CVC TECHNOLOGIES, INC. CVC 310 OPERATION MANUAL

16 - 1

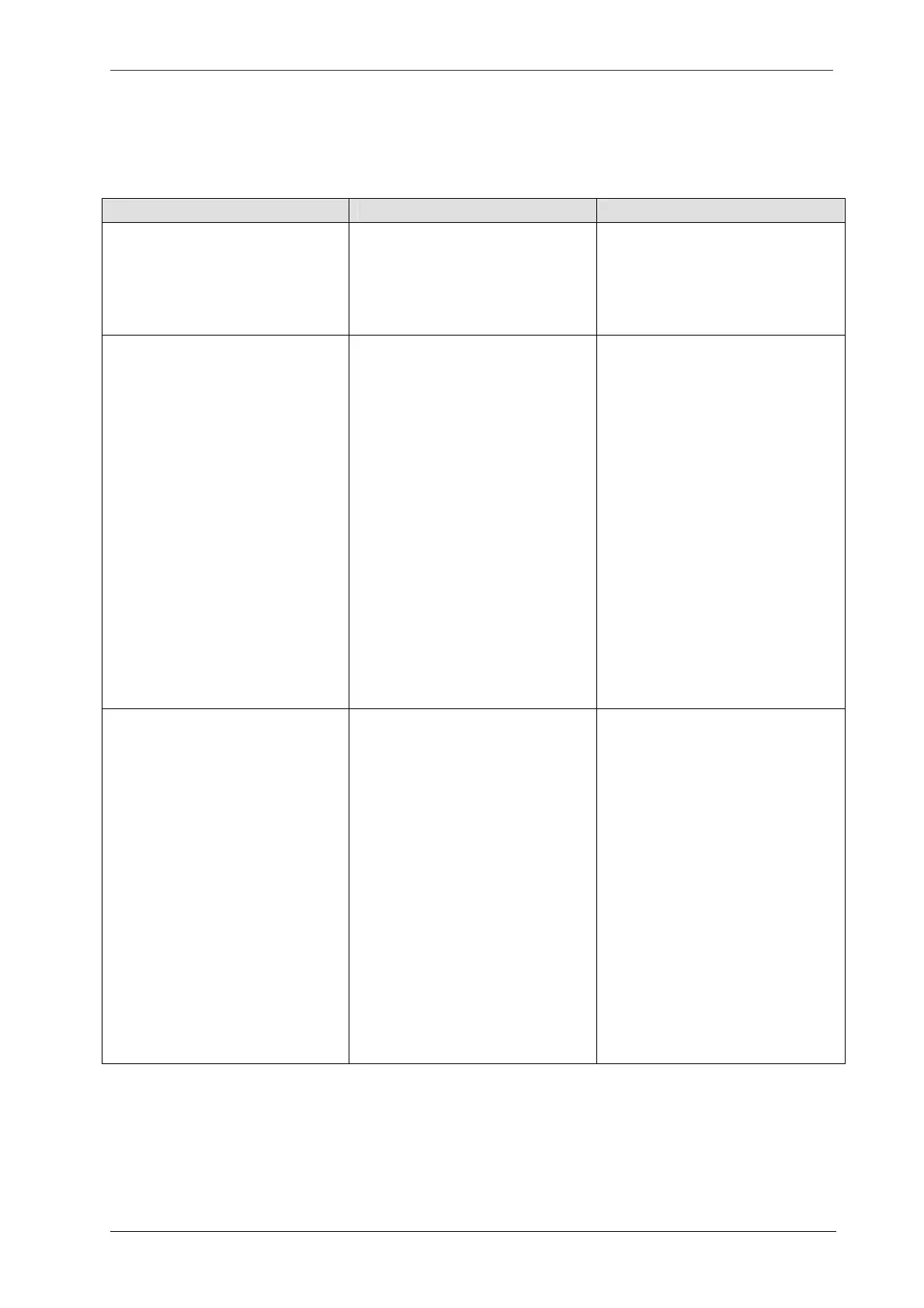

16. TROUBLESHOOTING

16.1 Troubleshooting for Labeling

Problem Possible Cause Suggested Solution

1. Label partially dispensed so that the

backing paper is pulled by container.

(This problem may make labeling

unstable or unavailable.)

a. Improper adjustment of label sensor

due to operator's not removing label

in front of label sensor.

b. Label sensitivity value too high

c. Transparent label.

a. Remove the label in front of label

sensor; use F1 (AUTO ADJ). (Refer

to chapter 10 Operating Instruction.)

b. Refer to "chapter 11 Label Sensor

Adjustment".

c. Use special sensor.

2. Label extension beyond peel blade

is not constant causing improper

label position.

(This problem will cause imprecise

labeling position)

a. Backing paper is loose between

label sensor and label peel blade.

b. Backing paper is too tight between

label sensor and label peel blade.

c. Advanced roller lock is unfastened.

d. Label extension length is too short

or none.

e. The gaps between the labels on the

backing paper are various.

f. The distances are various between

the edge of the labels and the edge

of backing papers, causing label

sensor to detect the different

starting points.

g. Label dispensing speed is too slow

to synchronize with conveyor

speed.

h. The connection screw between

driver roller and stepper motor is

loose.

a. Tighten the screw on the web

clamp.

b. Loose the screw on web clamp.

c. Lock the roller lock.

d. Adjust label extension from 1.5 mm

to 3mm.

e. Ask label roll supplier to correct it.

f. Ask label roll supplier to correct it.

g. Increase the label dispensing speed.

h. Tighten the screw.

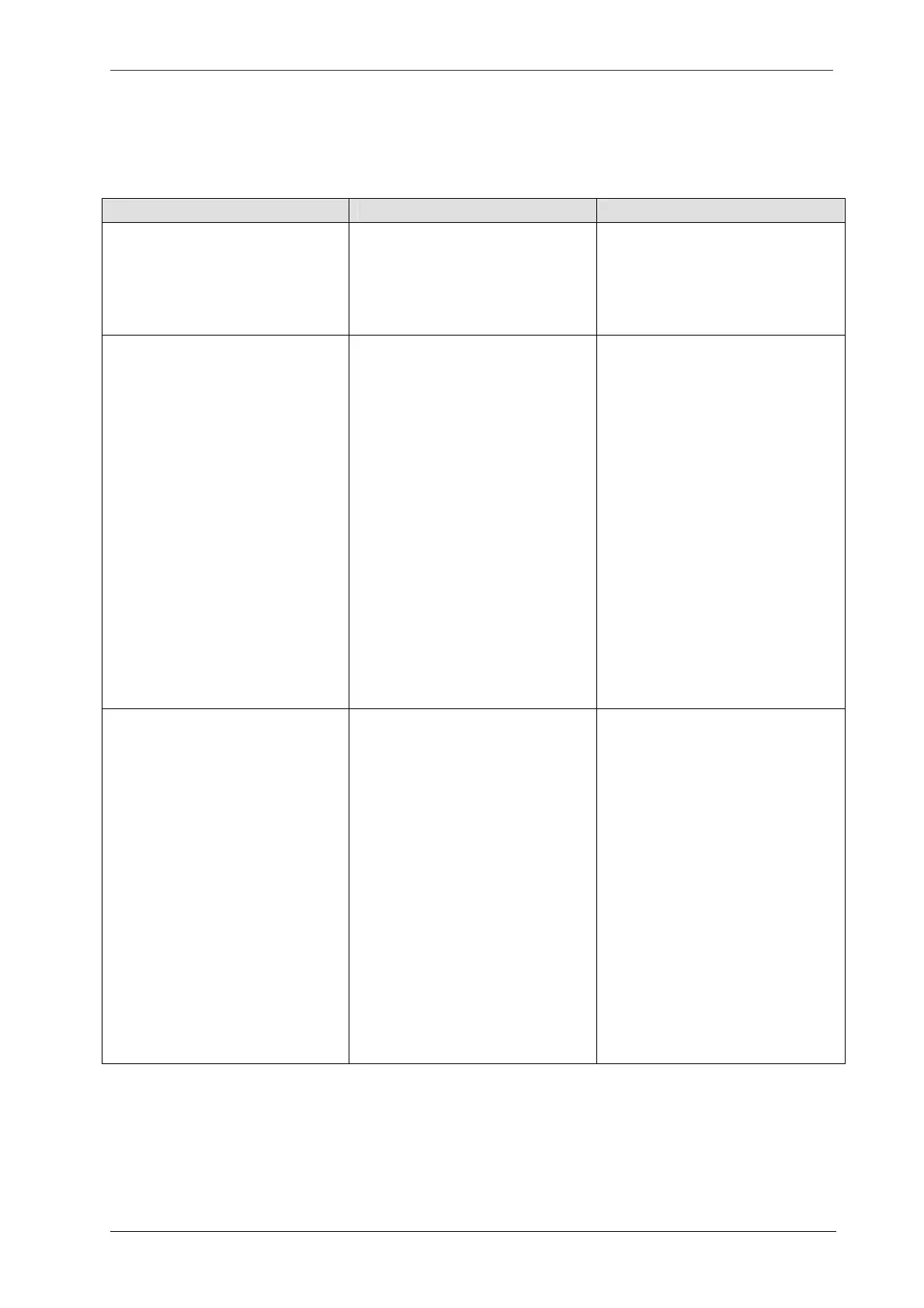

3. No label dispensing a. Label head is turned off.

b. Label sensor does not work.

c. Improper adjustment of product

sensor.

d. Product sensor does not work.

a. Check display panel.

b. If the red LED light on the sensor is

not lit, indicating the sensor is

malfunctioning.

If the LED light is lit, then move the

backing paper in the sensor slot to

check the backing paper value. If the

value shown on the screen is not

changed, indicating the sensor is

malfunction, and then replaces the

label sensor.

c. Refer to chapter 11 Product Sensor

Adjustment.

d. Check and make sure LD 5 indicator

(product sensor lamp) on the

master board is on. This light should

be always ON whenever the power

is turned on, and should be OFF

while label is being dispensed

Loading...

Loading...