CVC TECHNOLOGIES, INC. CVC 310 OPERATION MANUAL

11.5.3 Label Dispense Speed (LAB SPD) Adjustment

Generally, this parameter is automatically synchronized with wrap station by SelfSet

TM

, and no

adjustments are necessary. Only the following two situations, the adjustments are required:

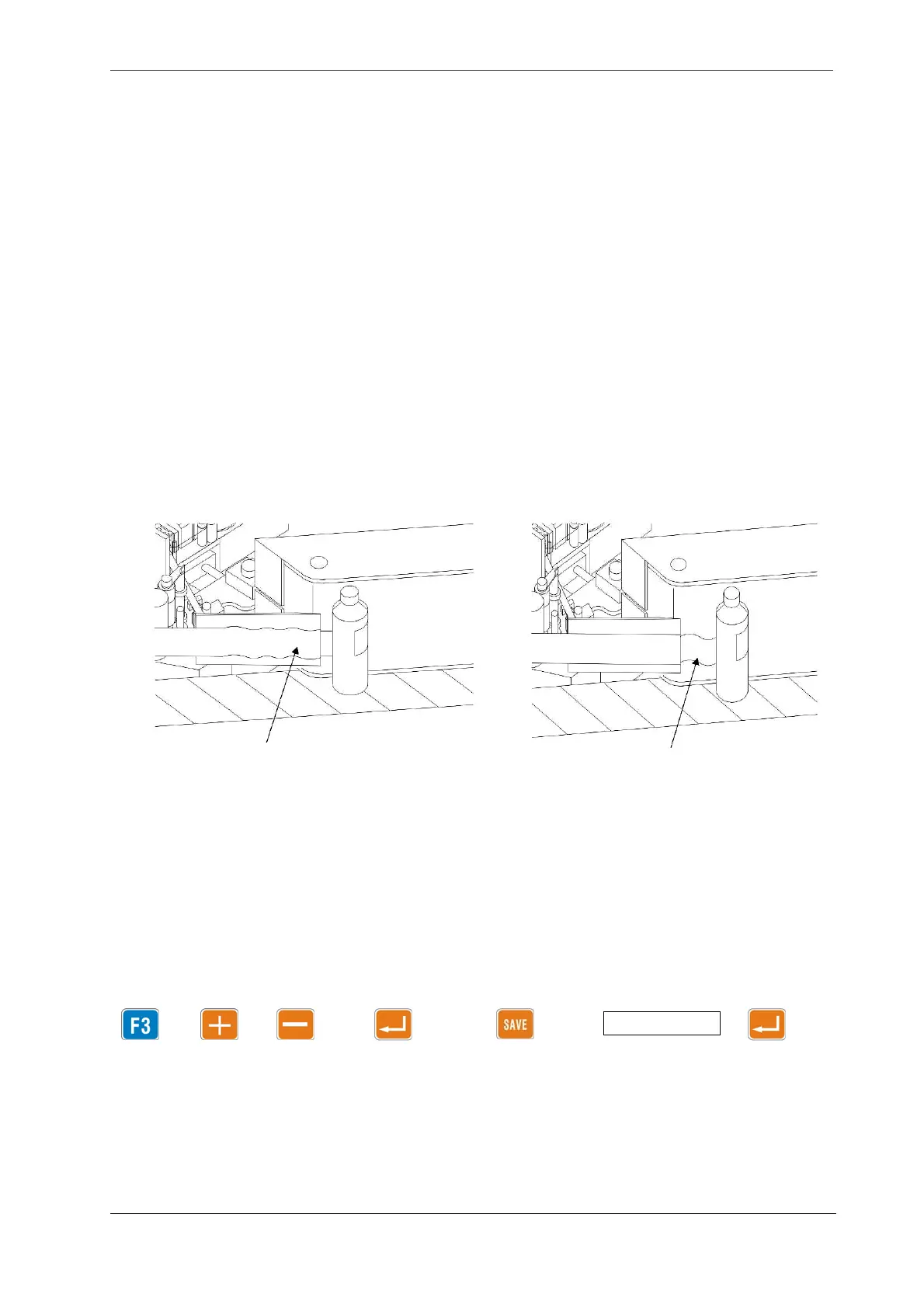

a. Backing paper is loose and not stretched out on the peel blade; this indicates wrapping speed is

faster than label dispensing speed. This appearance is not obvious; it is necessary to pay attention

to observe dispensing blade and backing paper to find this problem. This will leave label extension

unstable, causing the backing paper declination and poor labeling quality (FIG 11.5-1).

Countermeasure: Speed up the label dispensing speed.

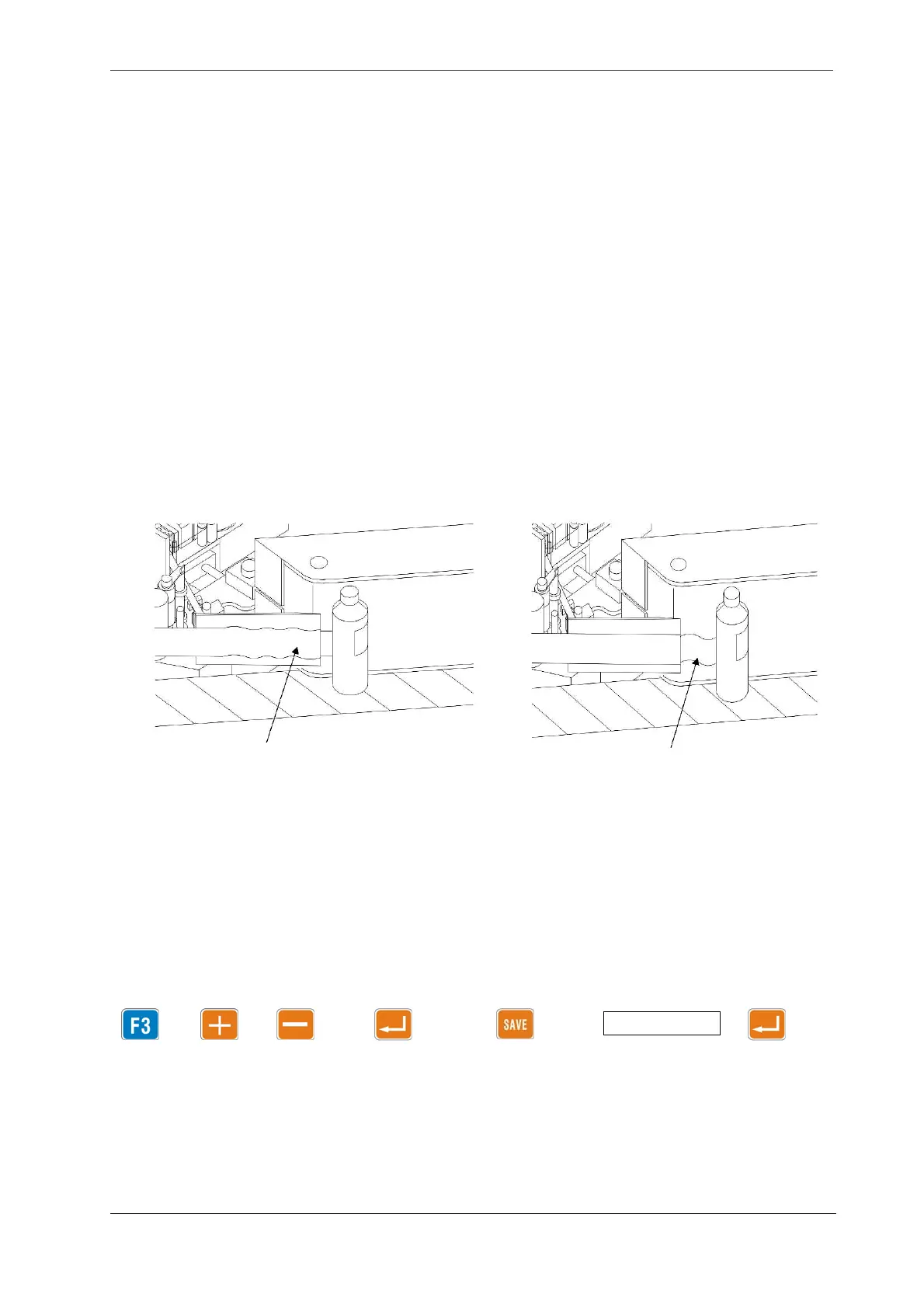

b. Label is loose and curved; this indicates label dispensing speed is faster than wrapping speed. This

will leave label wrinkle after labeling (FIG 11.5-2).

Countermeasure: Slow down the label dispensing speed.

Backing paper is loose and not

stretched out on the label peel blade

Label is loose and curve, label is

not stretched out on the wrap belt

Fig 11.5-1 Fig 11.5-2

c. The following figure shows correct labeling performance, the backing paper should be stretched out

on the peel blade, and the label should be pulled a little tight by the advancing bottle (FIG 11.5-3).

d. To save a new speed into memory:

→ or key → key → key → Memory (job) # → key.

11 - 5

Loading...

Loading...