CVC TECHNOLOGIES, INC. CVC 310 OPERATION MANUAL

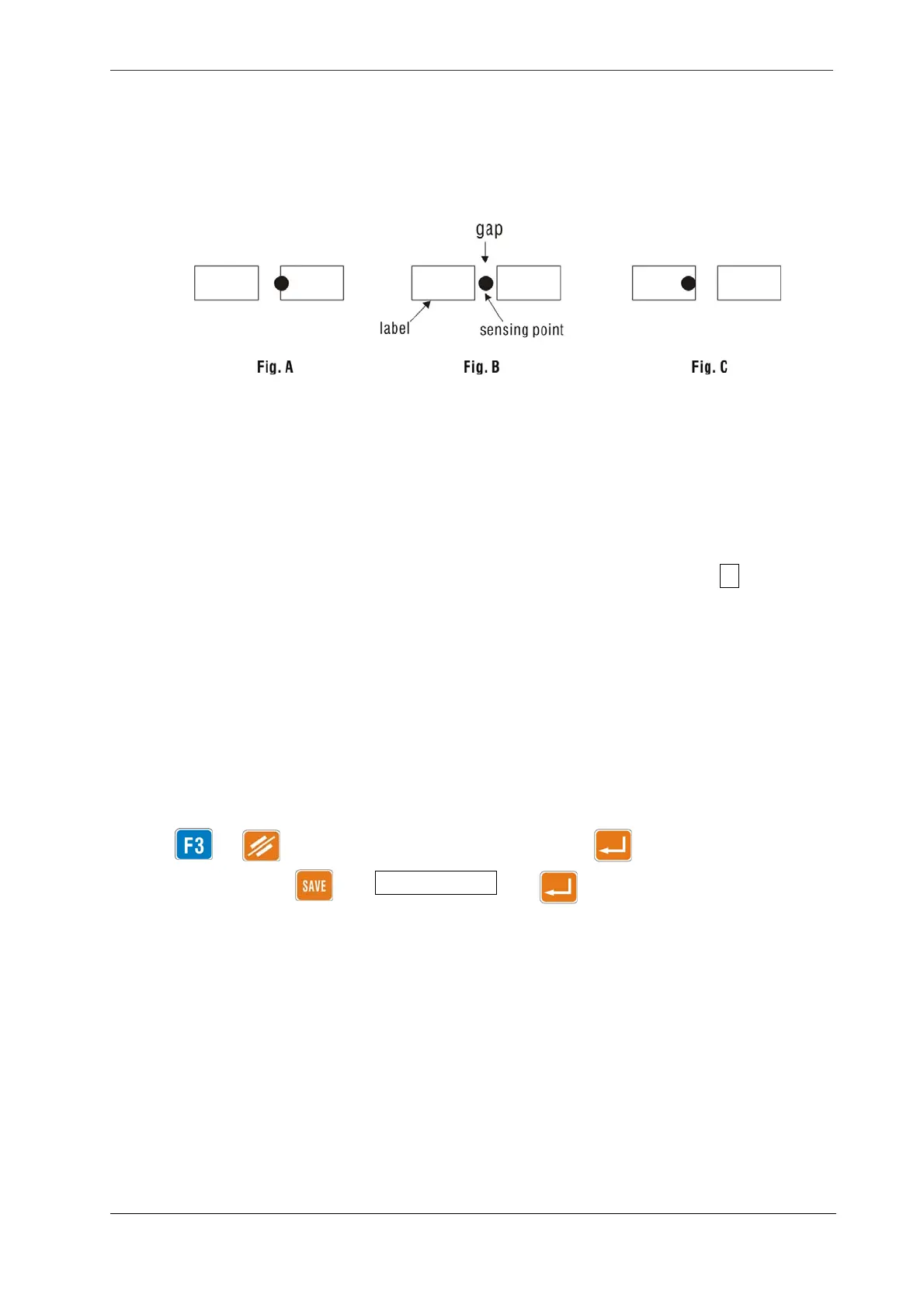

f. Two or more labels dispensing may also be caused by an incorrect detecting point of the label

sensor to label (e.g. If the sensor detecting point is positioned on the label edge as shown in Fig. A

& B). In these two cases, the label extension (EXTNSN) should be adjusted to shift the label

stopping position, thus the sensor detecting point will fully fall on the label (Fig. C).

O

Х

Fig

11.5-6

g. The thinner or clear label may be mistaken as gaps, causing incomplete label dispensing (half

labels), the label will be abnormally pulled out by the bottle. The reference value F3 (LAB SENS)

should be decreased to correct this problem.

h. Backing paper and label transmittance can be manually measured by pressing F2. Place either

backing paper or label in the label sensor slot to measure the transmittance value. The value

measured by this way may not represent the actual transmittance of the whole. Therefore, it is

recommended to have the minimum differences of 30 among the backing paper value, F3 (LAB

SENS) value and the label value.

i. Use a special label sensor if the value of the label sensitivity is very close to the value of backing

paper sensitivity.

j. Setting procedure:

Press → clear existing valve → enter new value → key

11 - 9

To save into memory: → Memory (Job) # →

Loading...

Loading...