Analog Output Control

Using the eldbus for analog output control requires:

• Drive parameter values set as dened below.

• Fieldbus controller supplied reference word(s) in the

appropriate location. (The location is dened by the

Protocol Reference, which is protocol dependent.)

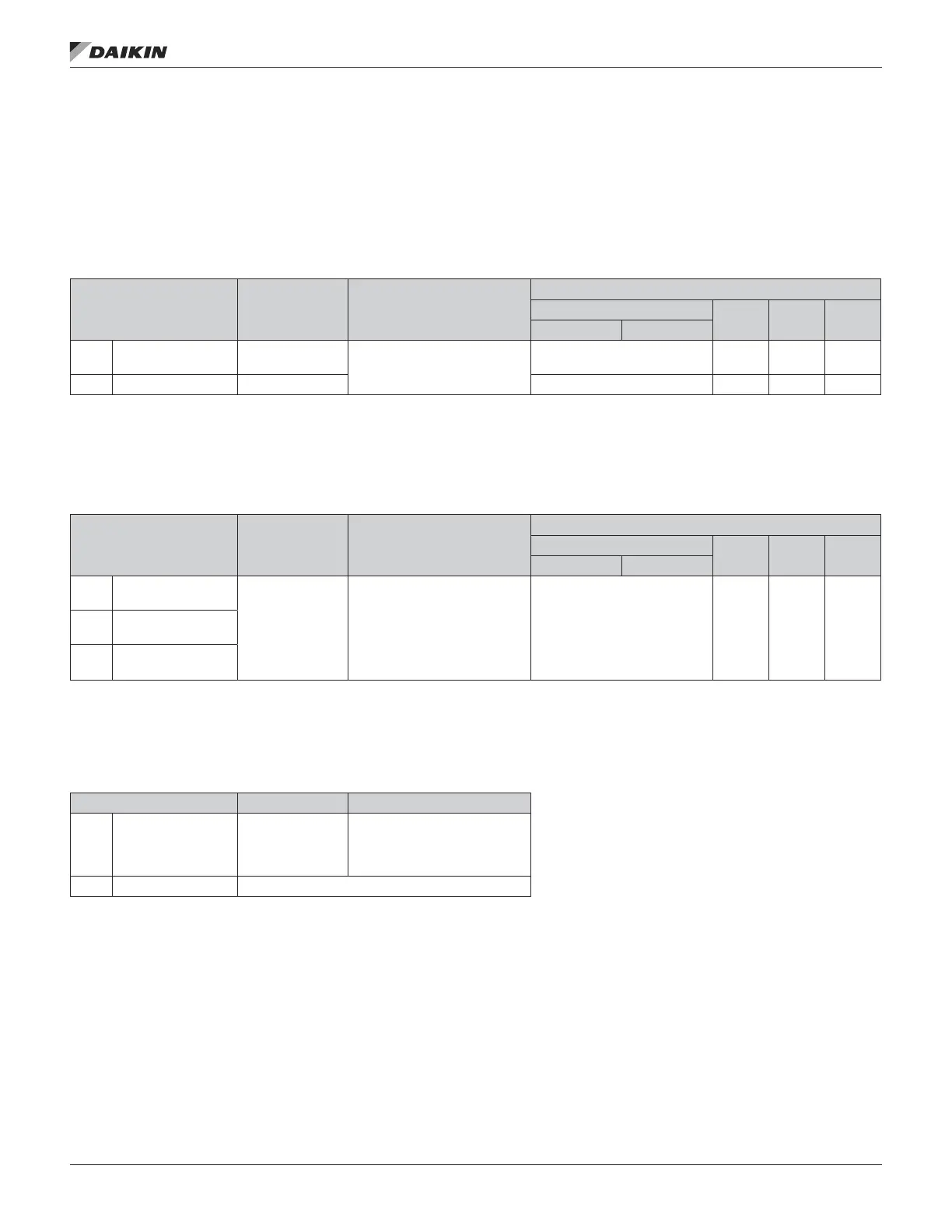

Table 55: Analog Output Control Protocol Reference

Drive Parameter Value Setting

Protocol Reference

Modbus

N2 FLN BACnet

abb drv dcu prole

1501 AO1 CONTENT SEL

135

(COMM VALUE 1)

Analog Output 1 controlled by

writing to parameter 0135.

— — — —

0135 COMM VALUE 1 — 40135 AO14 46 AO0

PID Control Setpoint Source

Use the following settings to select the eldbus as the setpoint source for PID loops:

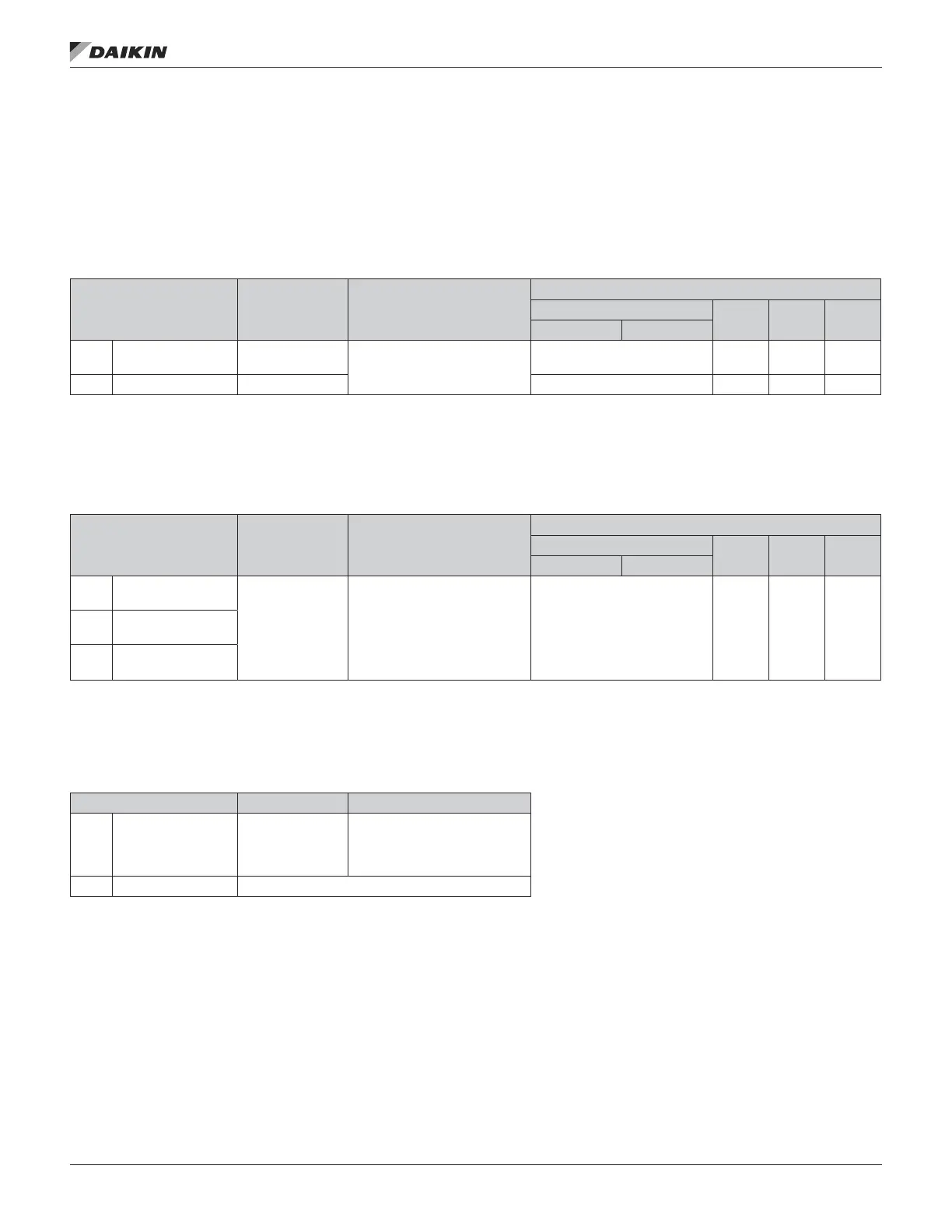

Table 56: PID Control Setpoint Source Protocol Reference

Drive Parameter Value Setting

Protocol Reference

Modbus

N2 FLN BACnet

abb drv dcu prole

4010

SET POINT SEL

(Set 1)

8 (COMM VALUE 1)

9 (COMM + AI1)

10 (COMM*AI1)

Setpoint is either: Input Reference

2 (+/-/* AI1). Control requires

parameter 1106 value = comm.

Process PID setpoint. Control

requires parameter 1106 value =

pid1 out and parameter 4010 value

= comm.

40003 AO2 61 AV17

4110

SET POINT SEL

(Set 2)

4210

SET POINT SEL (Ext/

Trim)

Communication Fault

When using eldbus control, specify the drive’s action if serial communication is lost.

Table 57: Communication Fault Reference

Drive Parameter Value Description

3018 COMM FAULT FUNC

0 (NOT SEL)

1 (FAULT)

2 (CONST SP7)

3 (LAST SPEED)

Set for appropriate drive response.

3019 COMM FAULT TIME Set time delay before acting on a communication loss.

OM 1190-1 • MD4 VFD 78 www.DaikinApplied.com

fIeldbus ConTrols

Loading...

Loading...