There are 3 types of closed-loop control:

•

Speed control. This type of control requires a speed PID feedback for an input. A properly optimized speed closed-

loop control has higher accuracy than a speed open-loop control. The speed control selects which input to use as

speed PID feedback in parameter 7-00 Speed PID Feedback Source.

•

Torque control. Used in ux mode with encoder feedback, this control oers superior performance in all 4

quadrants and at all motor speeds.

The torque control function is used in applications where the torque on the motor output shaft is controlling the

application as tension control. Torque control is selected in parameter 1-00 Conguration Mode, either in [4] VVC+

open loop or [2] Flux control closed loop with motor speed feedback. Torque setting is done by setting an analog,

digital, or bus-controlled reference. The maximum speed limit factor is set in parameter 4-21 Speed Limit Factor

Source. When running torque control, it is recommended to make a full AMA procedure since the correct motor

data is essential for optimal performance.

•

Process control. Used to control application parameters that can be measured by dierent sensors (pressure,

temperature, and ow) and be aected by the connected motor through a pump or fan.

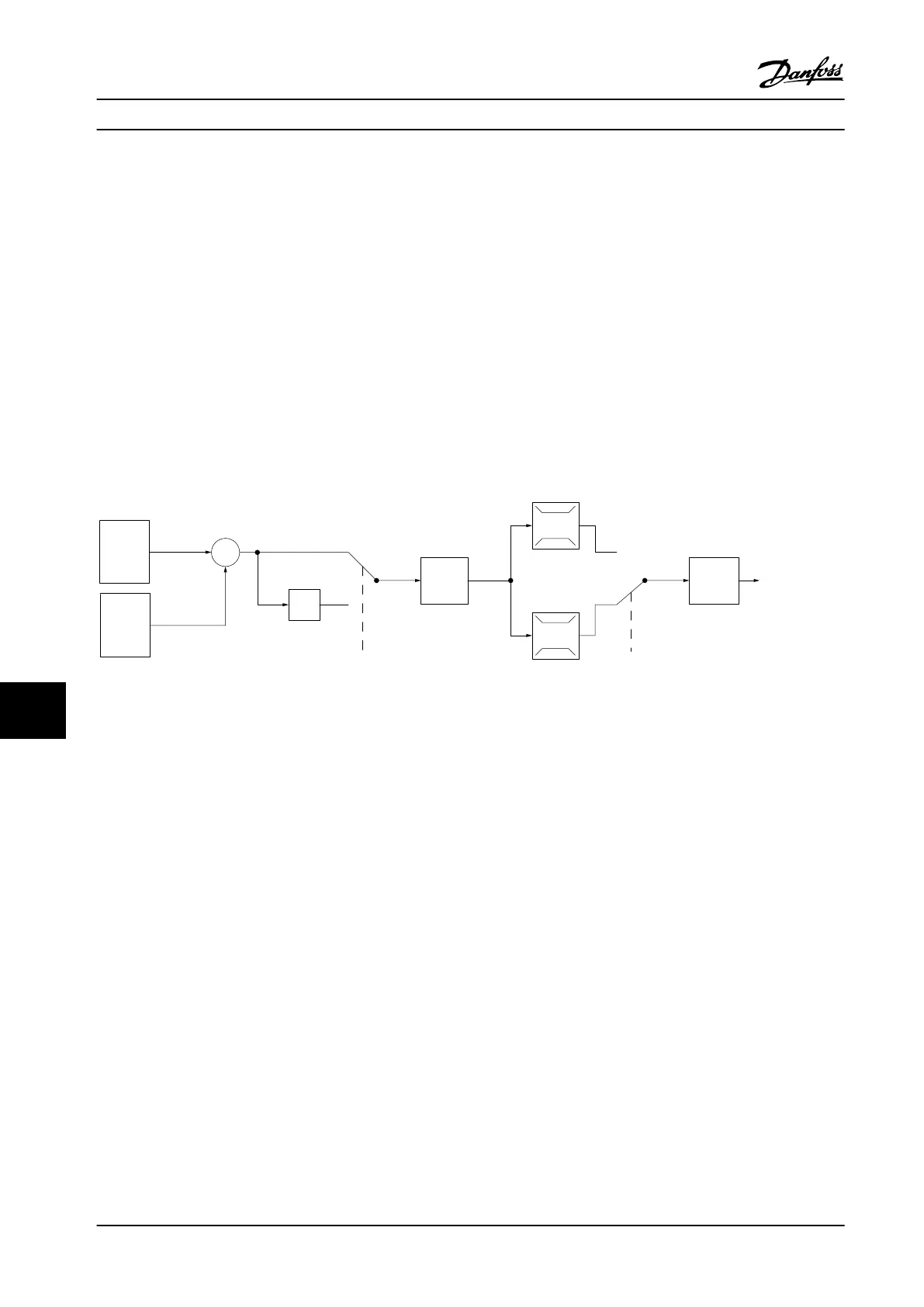

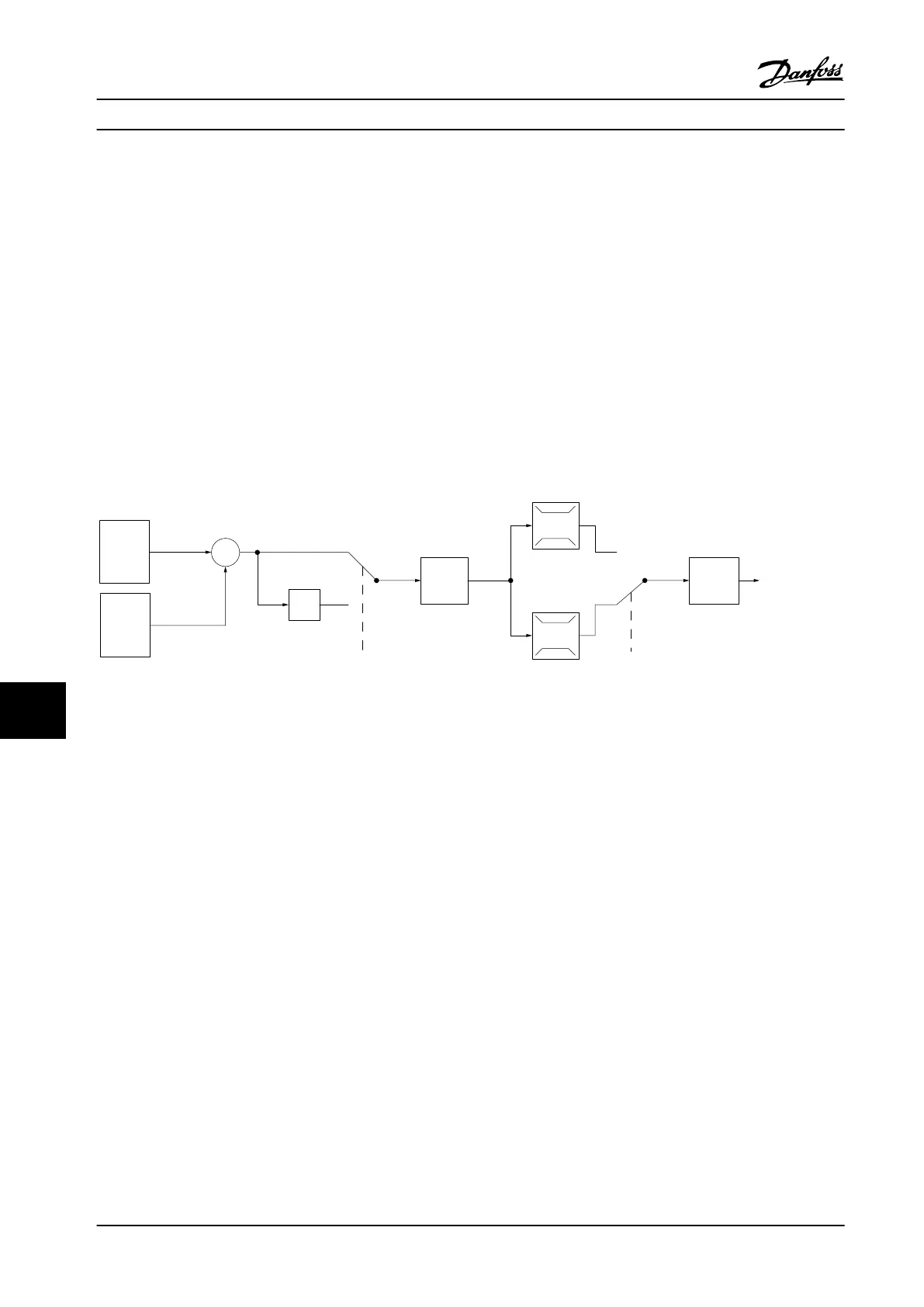

P 20-81

PID Normal/Inverse

Control

PID

Ref.

Handling

Feedback

Handling

Scale to

speed

P 4-10

Motor speed

direction

To motor

control

(Illustra-

tion)

(Illustra-

tion)

130BA359.12

100%

0%

-100%

100%

*[-1]

_

+

Figure 11.7 Block Diagram of Closed-loop Controller

Programmable features

While the default values for the drive in closed loop often provide satisfactory performance, system control can often be

optimized by tuning the PID parameters. Auto tuning is provided for this optimization.

•

Inverse regulation - motor speed increases when a feedback signal is high.

•

Start-up frequency - lets the system quickly reach an operating status before the PID controller takes over.

•

Built-in lowpass lter - reduces feedback signal noise.

11.2.7 Control Processing

See Active/Inactive Parameters in Dierent Drive Control Modes in the programming guide for an overview of which control

conguration is available for your application, depending on selection of AC motor or PM non-salient motor.

Basic Operating Principles ...

VLT

®

AQUA Drive FC 202

194 Danfoss A/S © 01/2018 All rights reserved. MG22B222

1111

Loading...

Loading...