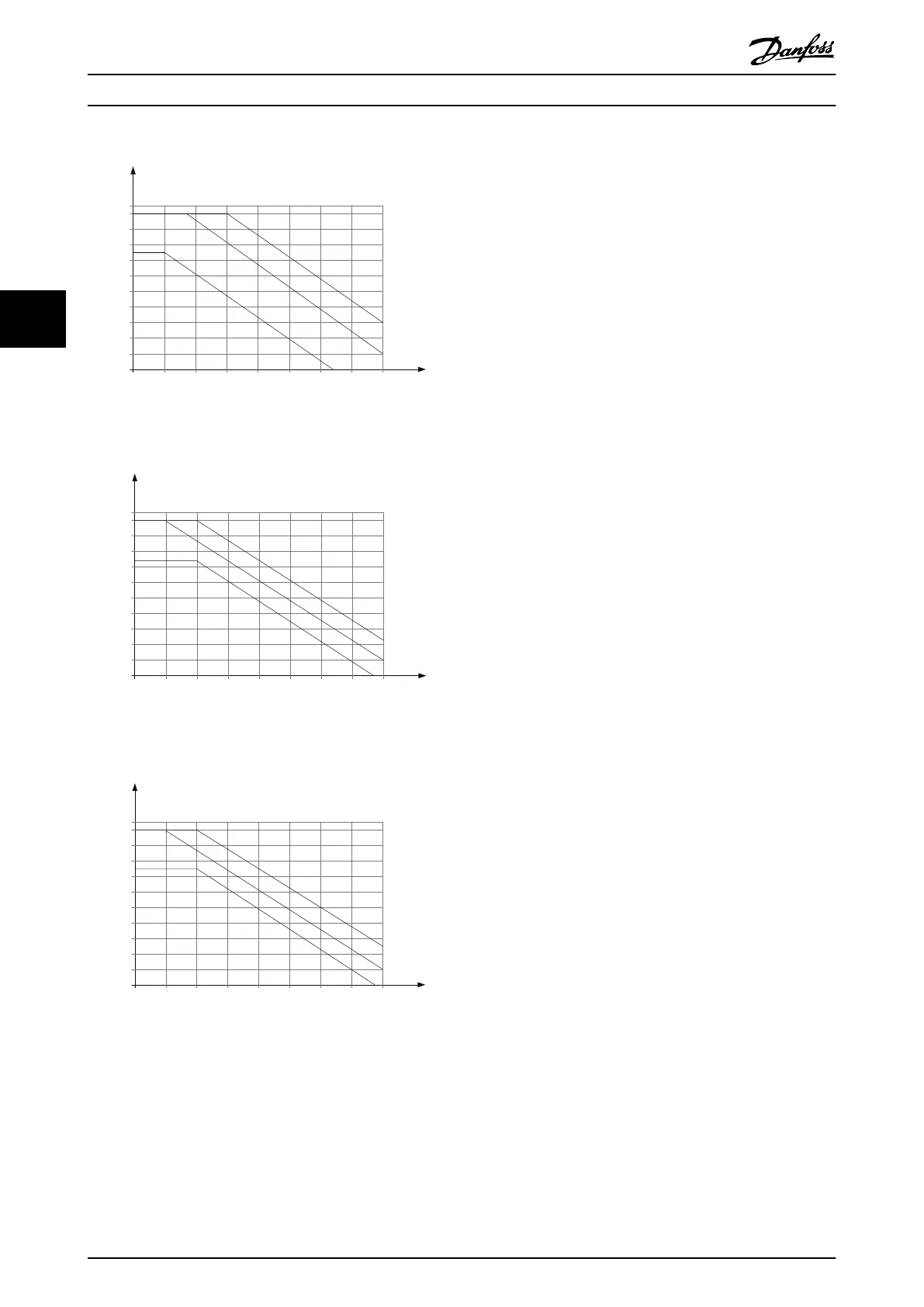

M3 400 V

fsw[kHz]20 64 108 1412

0

10 %

20

%

30 %

40 %

50 %

60 %

70 %

80 %

90 %

100 %

110

%

Iout [%]

16

40 ℃

45 ℃

50 ℃

130BC033.10

Illustration 4.40

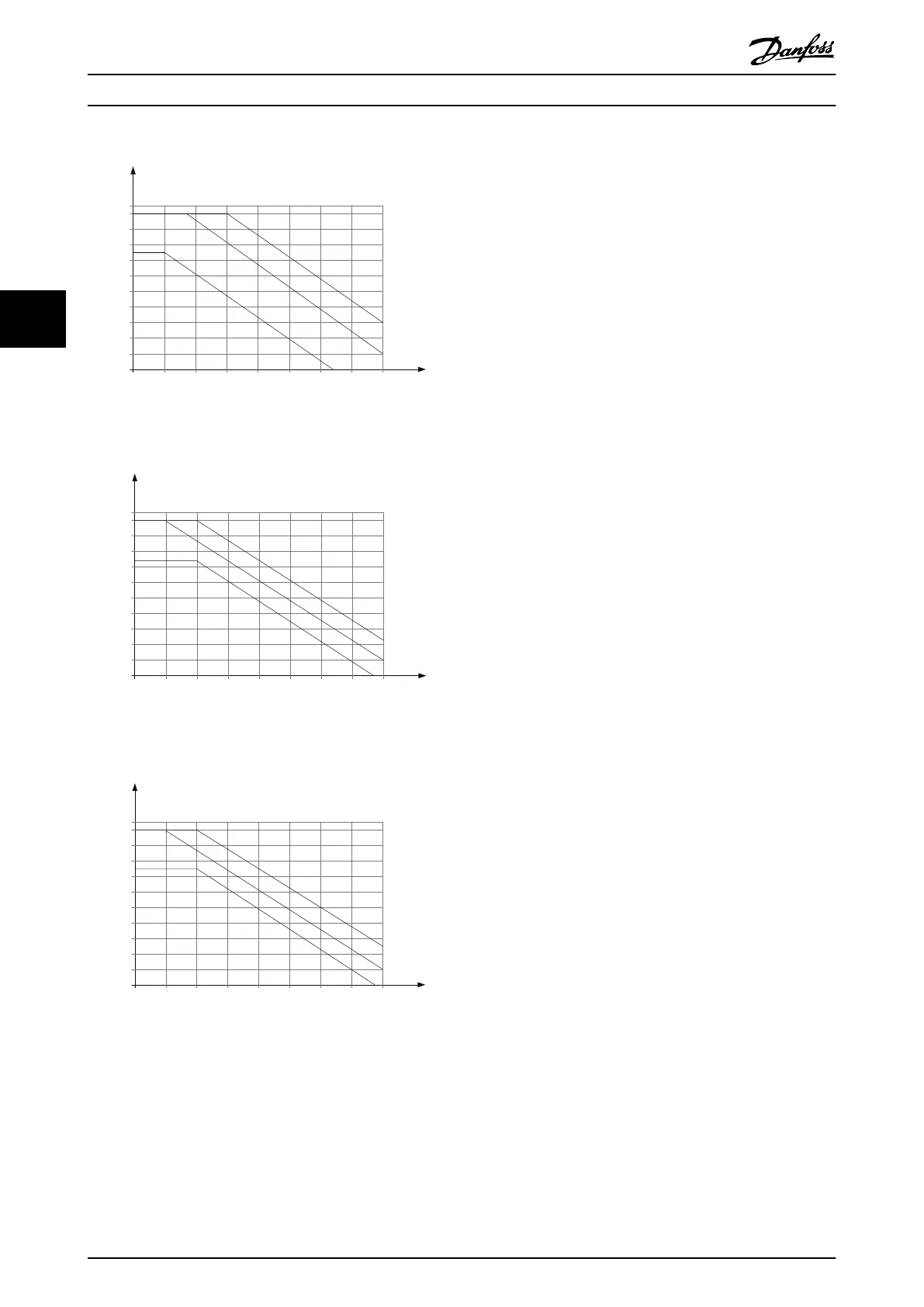

M4 400 V

fsw[kHz]20 64 108 1412

0

10 %

20

%

30 %

40 %

50 %

60 %

70 %

80 %

90 %

100 %

110

%

Iout [%]

16

40 ℃

45 ℃

50 ℃

130BC034.10

Illustration 4.41

M5 400 V

fsw[kHz]20 64 108 1412

0

10 %

20

%

30 %

40 %

50 %

60 %

70 %

80 %

90 %

100 %

110

%

Iout [%]

16

40 ℃

45 ℃

50 ℃

130BC035.10

Illustration 4.42

4.2.3 Derating for Low Air Pressure

The cooling capability of air is decreased at low air

pressure.

For

altitudes above 2000 m, contact Danfoss regarding

PELV.

Below 1000 m altitude no de-rating is necessary but above

1000 m the ambient temperature or the maximum output

current should be decreased.

Decrease the output by 1% per 100 m altitude above 1000

m or reduce the max. ambient temperature by 1 degree

per 200 m.

4.2.4 Automatic Adaptations to Ensure

Performance

The frequency converter constantly checks for critical levels

of internal temperature, load current, high voltage on the

intermediate circuit and low motor speeds. As a response

to a critical level, the frequency converter can adjust the

switching frequency and/or change the switching pattern

in order to ensure the performance of the frequency

converter. The capability automatically to reduce the

output current extends the acceptable operating

conditions even further.

4.2.5 Derating for Running at Low Speed

When a motor is connected to a frequency converter, it is

necessary to check that the cooling of the motor is

adequate. The level of heating depends on the load on the

motor, as well as the operating speed and time.

Constant torque applications (CT mode)

A problem may occur at low RPM values in constant

torque applications. In a constant torque application a

motor may over-heat at low speeds due to less cooling air

from the motor integral fan.

Therefore, if the motor is to be run continuously at an RPM

value lower than half of the rated value, the motor must

be supplied with additional air-cooling (or a motor

designed for this type of operation may be used).

An alternative is to reduce the load level of the motor by

choosing a larger motor. However, the design of the

frequency converter puts a limit to the motor size.

VLT

®

Micro Drive Selection VLT

®

Micro Drive FC 51 Design Guide

42 MG02K202 - VLT

®

is a registered Danfoss trademark

44

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Loading...

Loading...