6.18 Motor Installation

6.18.1 Motor Insulation

For motor cable lengths ≤

the maximum cable length

listed in 9.1 Specifications, the following motor insulation

ratings are recommended because the peak voltage can be

up to twice the DC link voltage, 2.8 times the mains

voltage, due to transmission line effects in the motor

cable. If a motor has lower insulation rating it

recommended to use a dU/dt or sine wave filter.

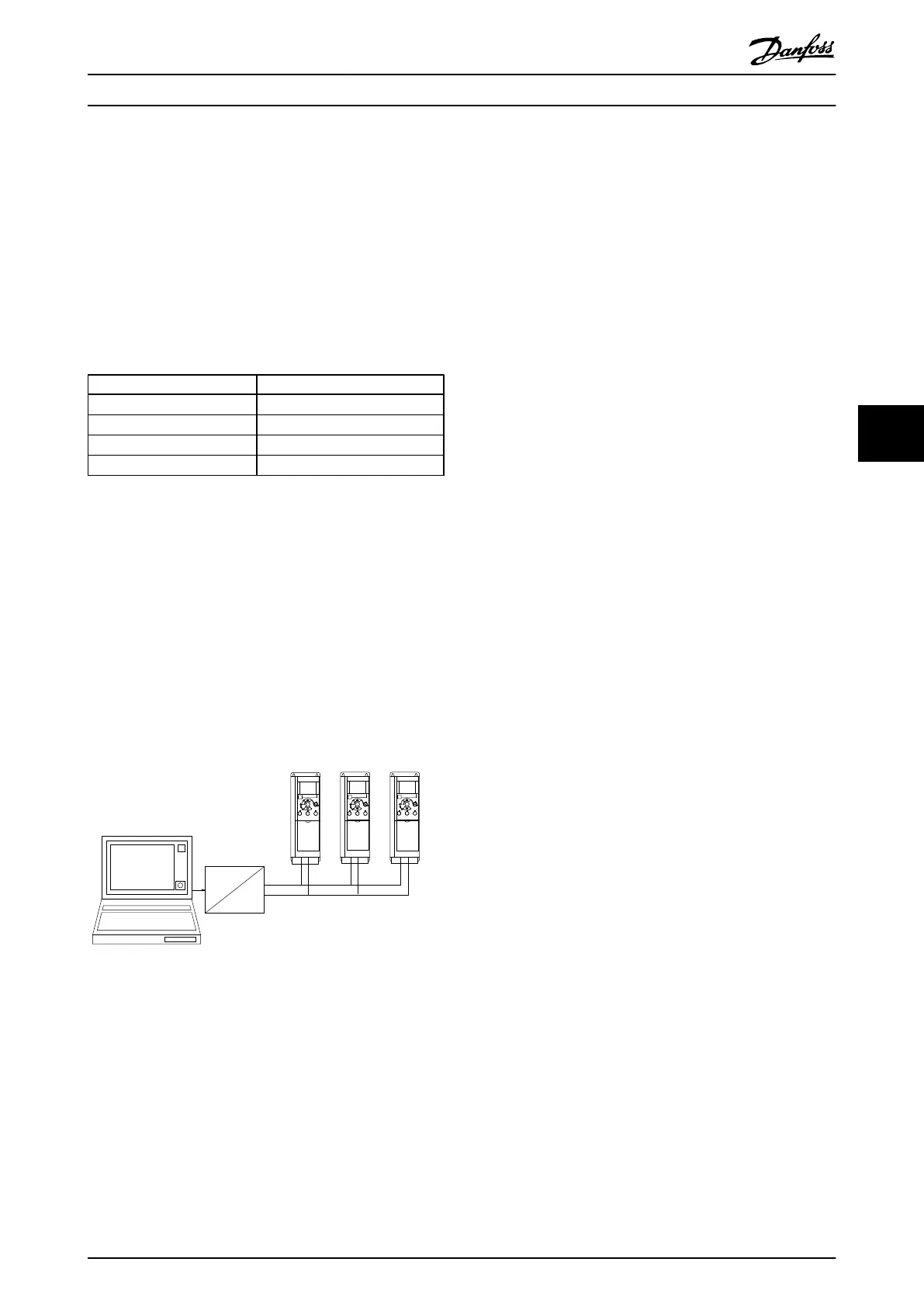

Nominal Mains Voltage Motor Insulation

U

N

≤420 V

Standard U

LL

=1300 V

420 V<U

N

≤500

V Reinforced

U

LL

=1600 V

500 V<U

N

≤600 V Reinforced U

LL

=1800 V

600 V<U

N

≤690 V Reinforced U

LL

=2000 V

Table 6.10

6.19 Installation of Misc. Connections

6.19.1 RS-485 Bus Connection

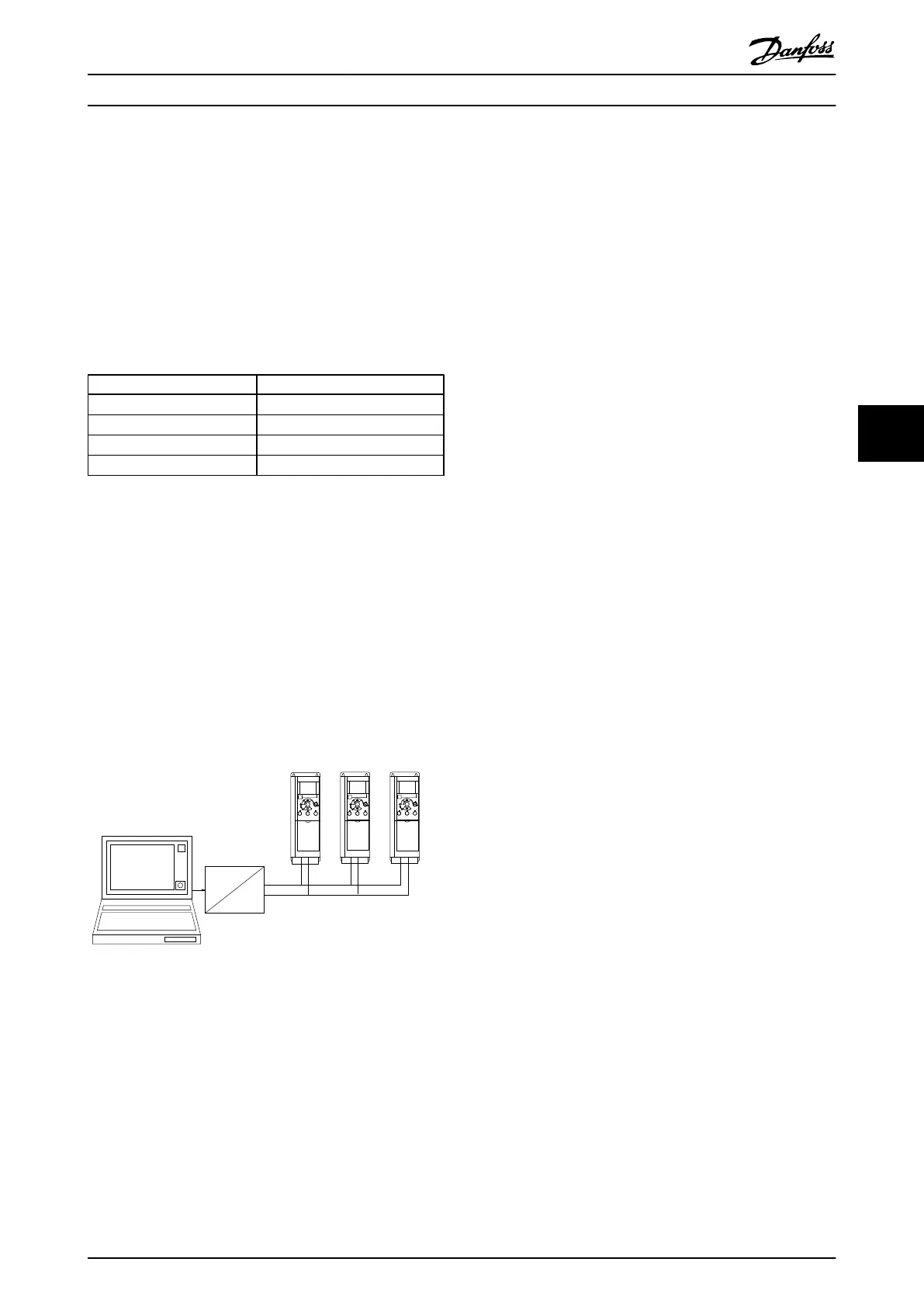

One or more frequency converters can be connected to a

control (or master) using the RS-485 standardized interface.

Terminal 68 is connected to the P signal (TX+, RX+), while

terminal 69 is connected to the N signal (TX-,RX-).

If more than one frequency converter is connected to a

master, use parallel connections.

130BC011.10

68 69 68 69 68 69

RS 485

RS 232

USB

+

-

Illustration 6.19

In order to avoid potential equalizing currents in the

screen, earth the cable screen via terminal 61, which is

connected to the frame via an RC-link.

Bus termination

The RS-485 bus must be terminated by a resistor network

at both ends. For this purpose, set switch S801 on the

control card for "ON".

For more information, see the paragraph Switches S201,

S202, and S801.

Communication

protocol must be set to 8-30

Protocol

.

6.19.2

How to Connect a PC to the

Frequency Converter

To control or program the frequency converter from a PC,

install the PC-based Configuration Tool MCT 10 Set-up

Software.

MCT 10 Set-up Software

MCT 10 Set-up Software has been designed as an easy to

use interactive tool for setting parameters in our frequency

converters.

The PC-based Configuration Tool MCT 10 Set-up Software

will be useful for:

•

Planning a communication network off-line. MCT

10 Set-up Software contains a complete

frequency converter database

•

Commissioning frequency converters on line

•

Saving settings for all frequency converters

•

Replacing a frequency converter in a network

•

Expanding an existing network

•

Future developed frequency converters will be

supported

Save Drive Settings

1. Connect a PC to the unit via USB com port

2. Open PC-based Configuration Tool MCT 10 Set-up

Software

3. Choose “Read from drive”

4. Choose “Save as”

All parameters are now stored in the PC.

Load Drive Settings

1. Connect a PC to the unit via USB com port

2. Open PC-based Configuration Tool MCT 10 Set-up

Software

3. Choose “Open”– stored files is shown

4. Open the appropriate file

5. Choose “Write to drive”

All parameter settings are now transferred to the

frequency converter.

A separate manual for PC-based Configuration Tool MCT

10 Set-up Software is available.

How to Install

VLT

®

Micro Drive FC 51 Design Guide

MG02K202 - VLT

®

is a registered Danfoss trademark

61

6 6

Buy: www.ValinOnline.com | Phone 844-385-3099 | Email: CustomerService@valin.com

Loading...

Loading...