AutoLab TF Dispenser Technical Manual – Revision 5

AutoLab TF dispensers Technical Manual TFTMTF / Rev 5.0 / 24

th

May 2006 Page 147 of 150

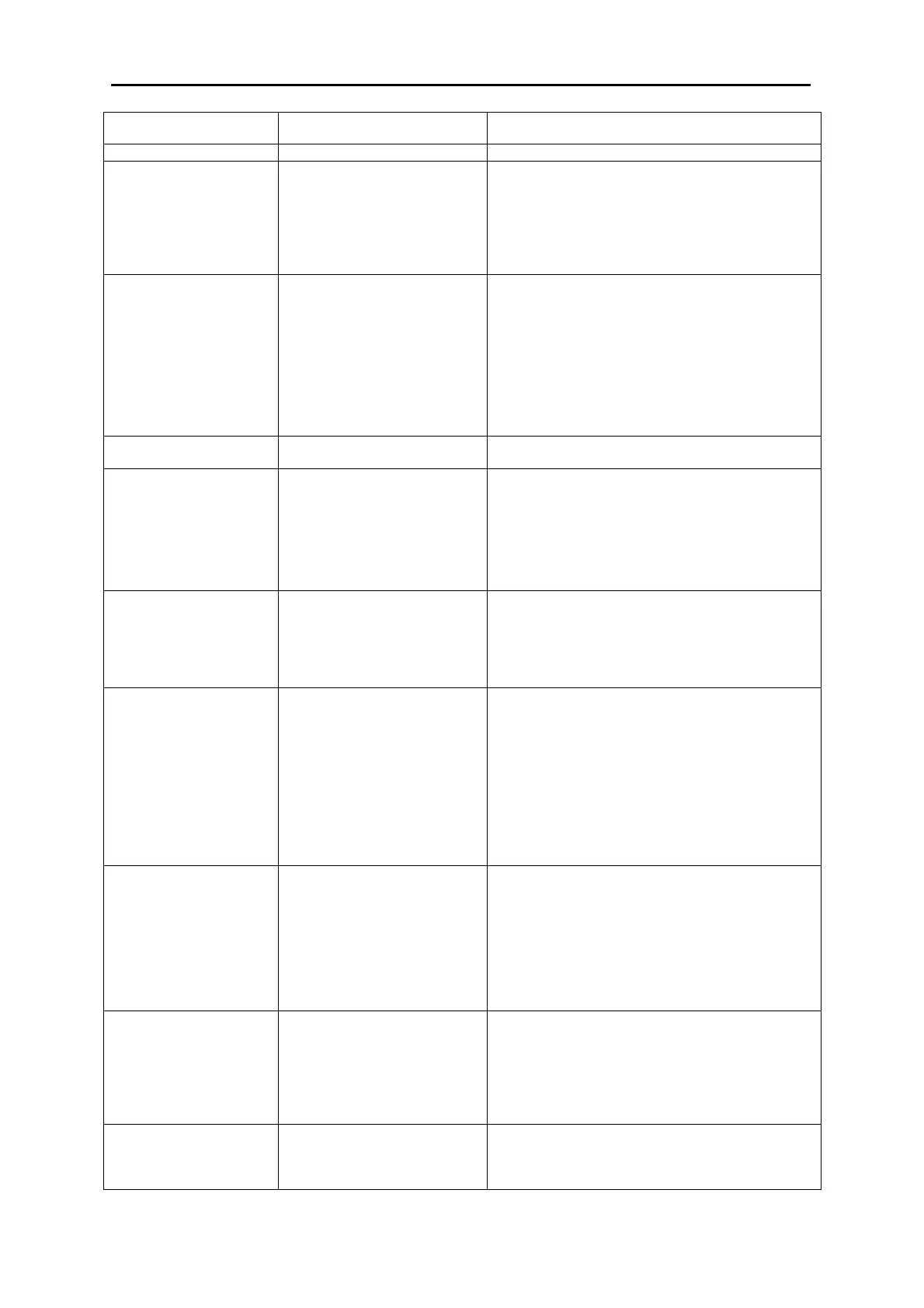

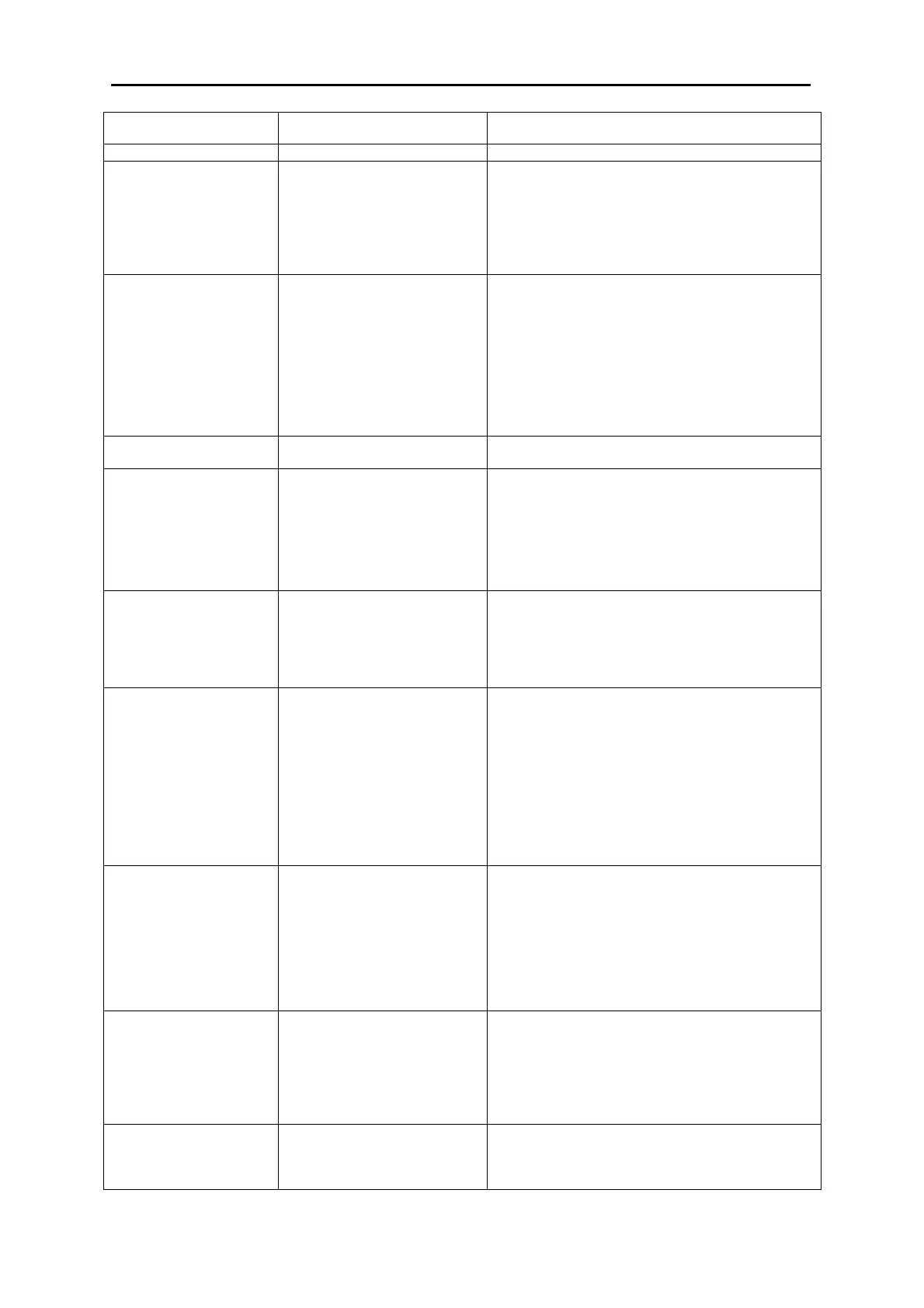

ERROR MESSAGE CAUSES

SOLUTION

iii. Replace the LA50B servo module.

Robot Can Not Reset Reset sensor failure 1. Check that if the reset sensor works properly. If

not replace the sensor. If yes re-adjust the

position of reset sensor.

2. Replace LA50B servo module.

3. Check that if the robot works properly. If not,

check that if the servo amplifier shows warning.

4. Check if all the safety doors are closed.

Can’t turn on scale 1. Vibration on floor.

2. Air flow inside the machine.

3. Defective scale.

1. Install the anti-vibration material, such like rubber

pad to check if can resolve the vibration.

2. Take the scale to a non-vibrate and non-air flow

environment and turn on scale to check if

problem caused by above. If not, replace the

scale

3. Ensure anti-wind acrylic plate and rubber skirt

have been installed.

4. Ensure the doors are all close during power on

machine.

Can Not Reset Scale 1. Can’t read data from scale.

2. Scale unstable.

Refer to “Can’t read data from scale” and” Scale

unstable”.

Can Not Read Data From

Scale

1. Scale is off.

2. Communication failure.

1. Check that if the power line of the balance is

connected properly.

2. Check the communication by following:

i. Check the connection of the RS232 cable.

ii. Replace the RS232 cable if it is defective.

iii. Check the setting of the scale.

iv. Replace the scale if it is defective.

Scale Unstable Bad environment will affect the

stability, like as wind blows to

balance directly, vibration, high

frequency and magnetic field,

etc.

1. Check if the scale is level.

2. To eliminate affected causes (wind, vibration

and high magnetic filed etc).

3. Replace the scale if it is defective.

4. Check that the container is on scale stable and

no touch other objects.

Agitation failure 1. Agitation pulley needs

lubrication.

2. Drive wheel of agitation

motor is loosen.

3. Connector of agitation

motor loosen.

4. Agitation motor failure.

5. Agitation controller failure.

6. Agitation control board

failure.

7. Agitation belt broken.

1. Grease the agitation pulley.

2. Ensure connector is in well connection.

3. Fix the drive wheel.

4. Replace agitation motor to assure its

defectiveness.

5. Replace agitation controller to assure its

defectiveness.

6. Replace agitation control board(DS Relay

Board)to assure its defectiveness.

7. Replace agitation belt.

Agitation Not Smooth 1. The bottom of glass bottle is

not flat.

2. The stirrer is worn.

3. The bearing of agitation

pulley is worn.

4. The bearing of agitate motor

is worn.

5. The agitation belt is not with

correct adjustment.

1. Replace the defective bottle.

2. Replace the defective stirrer.

3. Grease the bearing of agitation pulley.

4. Replace the defective pulley.

5. Adjust the fix position of agitation motor to

ensure the agitation belt is set to a tighten

position. Please notice the belt should be

tension but not very tight.

Agitation Noisily 1. Agitation motor is noisy.

2. Agitator makes noise.

3. The belt of agitation is not

adjusted correctly.

1. Adjust agitation motor position and lubricate the

motor.

2. Check if the pulleys work properly and

smoothly; if not, lubricate it.

3. Adjust the position and tension of belt.

4. Check agitation belt is not too loose or tight and

lubricate by belt wax.

Auto-Refill Failure Water tank can’t auto-refill 1. No water supplied from main water source.

2. The water pressure regulator adjusted to wrong

or lower pressure.

3. Replace the floater to assure its defectiveness.

Loading...

Loading...