AutoLab TF Dispenser Technical Manual – Revision 5

AutoLab TF dispensers Technical Manual TFTMTF / Rev 5.0 / 24

th

May 2006 Page 148 of 150

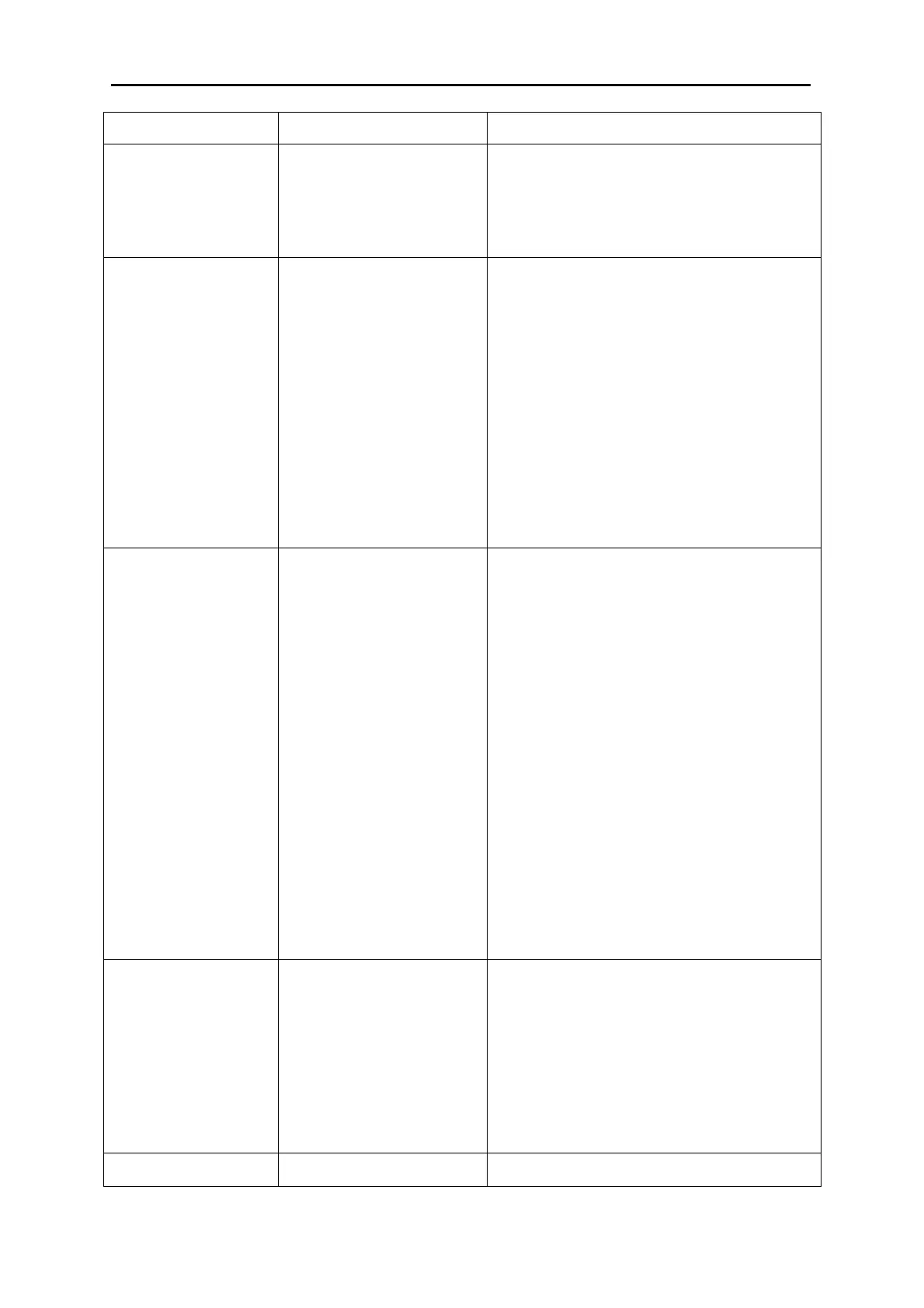

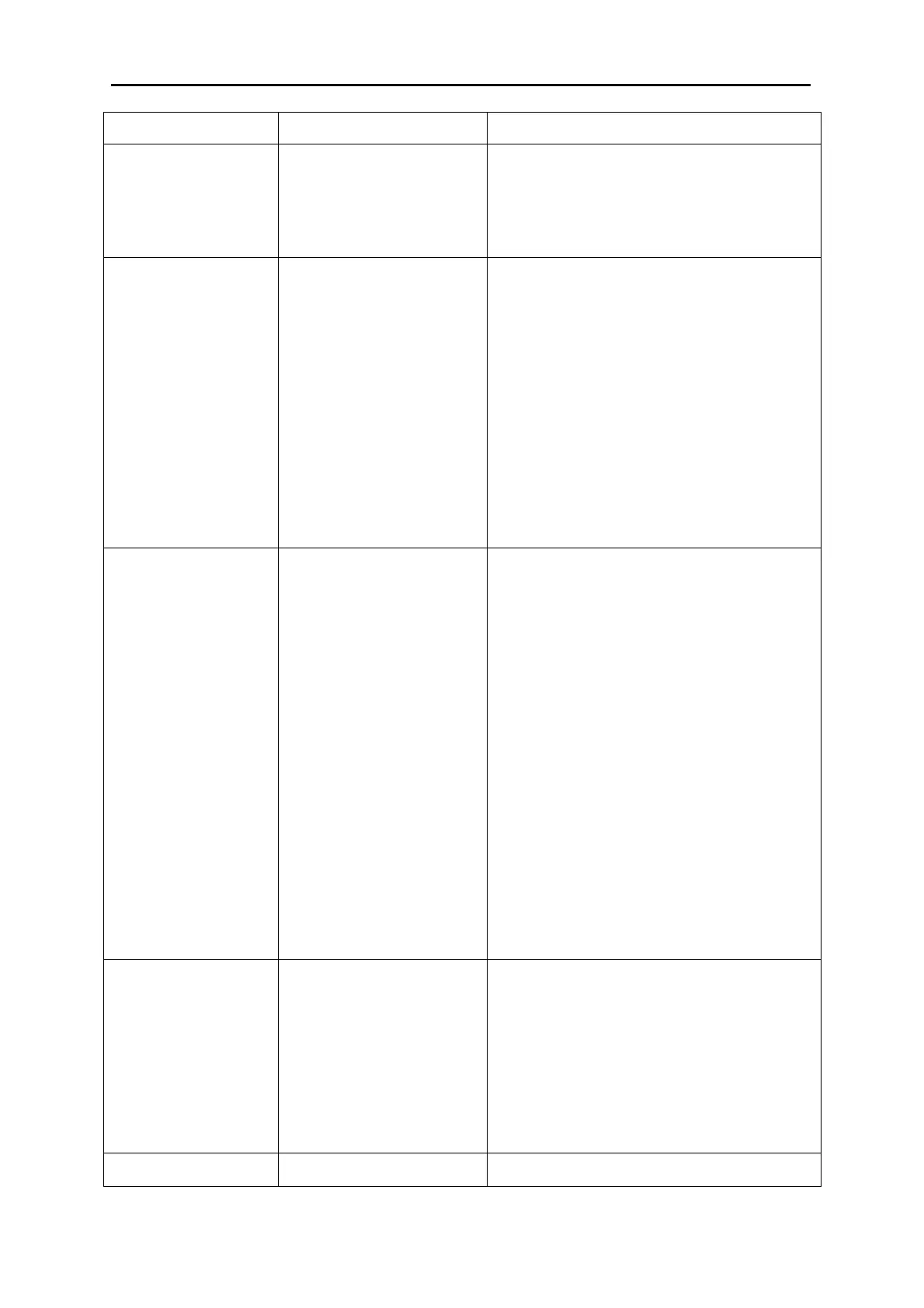

ERROR MESSAGE CAUSES

SOLUTION

Find air cylinder move not

smoothly

1. Air cylinder is not lubricated

for a while.

2. Air pressure inlet and outlet

on fast-fit connectors are not

adjusted correctly.

1. Recommend to grease the arm of air cylinder

monthly. But the frequency should be depended

on the environment quality of Lab.

2. Adjust the air pressure on inlet and outlet fast-fit

connectors to ensure the cylinder move

smoothly, not too fast and not to slow to cause

vibrated movement.

Dye Pot Tray Is Unable

To Move Into Dispense

Position

(AutoLab TF

88/128/168)

1. Inlet conveyor failure

2. Inlet limit sensor failure

3. The tray inlet cylinder

failure

1. Check the inlet conveyor by following:

a. Check the output bit7 LED of No.0 LA50B

DIO module illuminated? If not replace the

PLC. If yes, check the SSR-1 and replace it

if defective.

b. Check the capacitor of conveyor motor

works properly.

2. Check the limit sensor by following:

a. Check the output bit10 LED of No.0 LA50B

DIO module illuminated? If not replace the

PLC.

b. Check the signal line connects properly.

c. Check the sensor work properly? If not

replace the sensor.

3. Check the front/middle magnetic sensors of the

conveyor inlet cylinder work properly? If not

replace the sensor.

Dye Pot Tray Is Unable

Move To Outlet Conveyor

(AutoLab TF

88/128/168)

1. Middle conveyor failure

2. Outlet limit sensor failure

3. Outlet cylinder failure

4. Outlet conveyor failure

1. Check the middle conveyor by following:

a. Check the output bit11 LED of No.0

LA50B DIO module illuminated? If not

replace the PLC. If yes, check the SSR-2

and replace it if defective.

b. Check the capacitor of conveyor motor

works properly.

2. Check the limit sensor by following:

a. Check the output bit12 LED of No.0

LA50B DIO module illuminated? If not

replace the PLC.

b. Check the signal line connects properly.

c. Check the sensor work properly? If not

replace the sensor.

3. Check the front/back magnetic sensors of the

conveyor outlet cylinder work properly? If not

replace the sensor.

4. Check the outlet conveyor by following:

a. Check the output bit9 LED of No.0

LA50B DIO module illuminated? If not

replace the PLC. If yes, check the SSR-3

and replace it if defective.

b. Check the capacitor of conveyor motor

works properly.

Dye pot tray is unable to

move in dispense area.

1. Not to push “CONFIRM”

button.

2. The dye pot tray push

cylinder is not detected at

“front” position.

3. The dye pot tray U/D

cylinder is detected at

“down” position.

4. Air pressure too low for

cylinder to active.

5. Main air pressure is not

enough.

1. Press “CONFIRM” push button.

2. Check if the magnetic sensor of front position of

dye pot tray push cylinder works? If not, replace

the magnetic sensor.

3. Check if the magnetic sensor of down position of

dye pot tray U/D cylinder works? If not, replace

the magnetic sensor.

4. Adjust the air inlet pressure at fast-fit connector

to ensure enough pressure to move cylinder.

5. Ensure the air pressure is set to 4.5~6.0 kg/cm

2

.

6. Ensure the main air pressure is ON.

Dye pot tray is unable to

move to down position to

1. The dye pot tray U/D

cylinder is detected at

1. Check if the magnetic sensor of down position of

dye pot tray U/D cylinder works? If not, replace

Loading...

Loading...