ASDA-B2 Chapter 2 Installation

Revision May, 2018 2-7

2.4.4 Precautions for Using Couplings

Caution:

It is suggested to use a flexible coupling specifically designed for servo motors, especially

double spring couplings, which provide some buffer tolerance during eccentric motion and

deflection. Please select appropriate coupling size for the operating conditions. Improper

usage or connection may result in damage.

1. The anti-rust coating or oil on the motor shaft end must be wiped off.

2. If using a servo motor with a keyway, attach the supplied key or use a key that

matches the dimensions of the drawing to the motor shaft.

Note: when installing the key on the motor, do not apply excessive force to the keyway or

motor shaft.

3. Use dial gauge or other methods to ensure that the centering accuracy is within the

specification. If you cannot use the dial gauge or other methods, you can slide the

coupling along both axes and adjust it until it does not get stuck.

4. Servo motor shaft installation safety precautions

(1) When connecting the shaft, make sure that the required centering accuracy is

reached. If the shaft is not correctly centered, vibration may damage the bearings

and encoder.

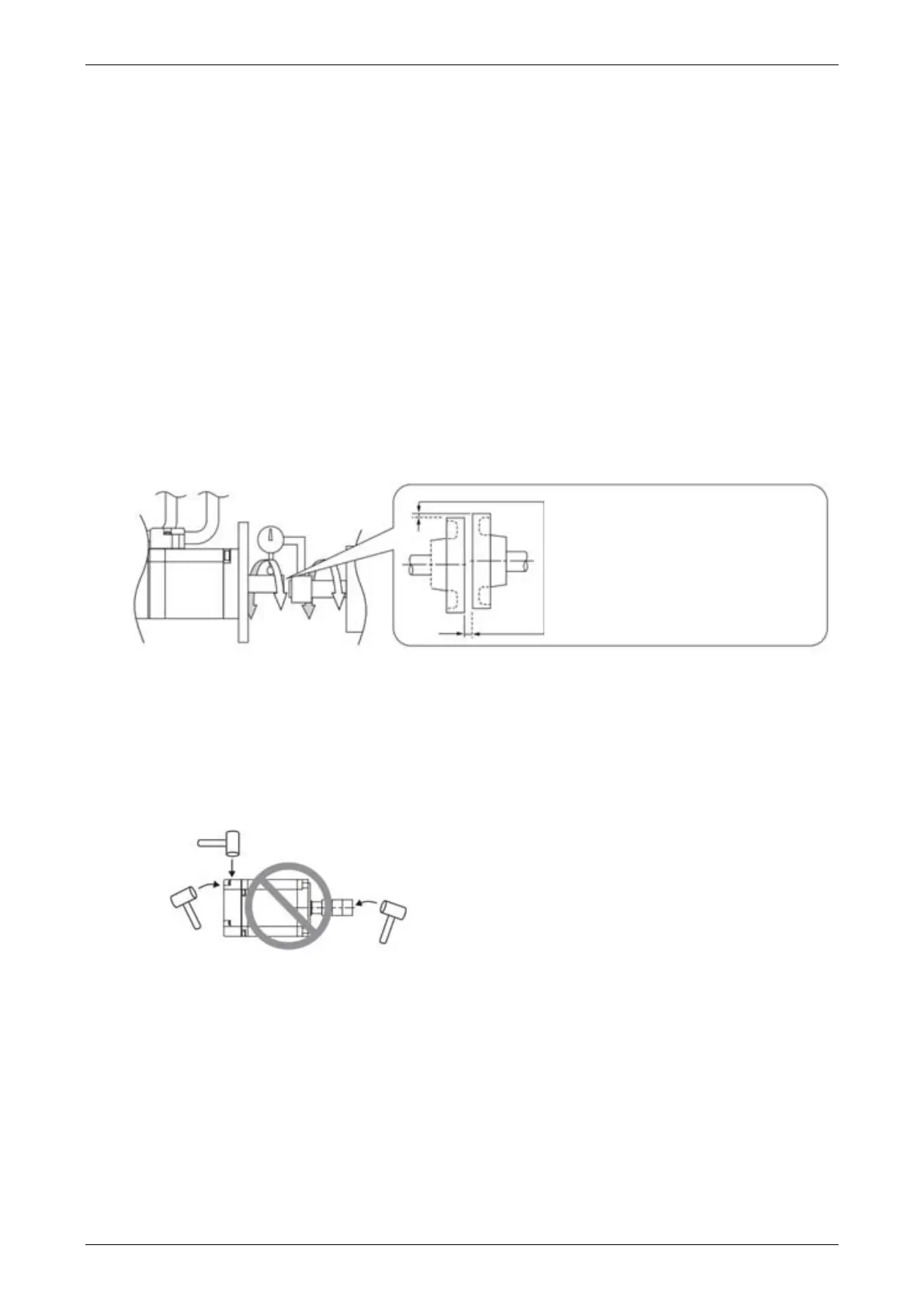

(2) When installing the coupling, do not apply excessive force to the shaft. Also, do

not apply excessive force to the area around the encoder, as the impact may

damage the encoder.

(3) If the coupling makes any abnormal noise, please re-align the shaft until the noise

disappears.

(4) Make sure that the axial load and radial load are within the specifications. Please

refer to the specifications for the maximum axial load (N) and maximum radial

load (N) for each servo motor.

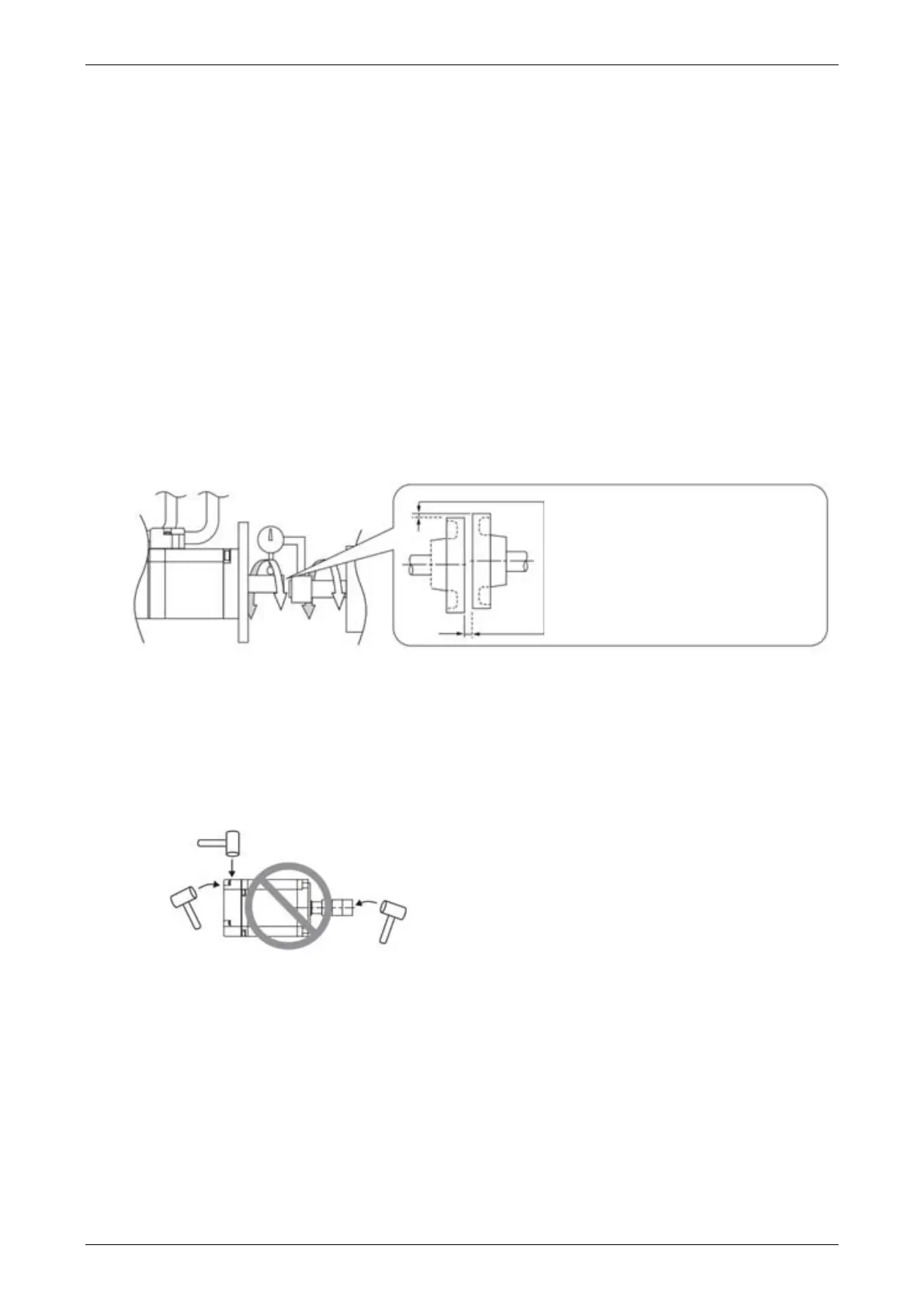

This distance is measured at four different

positions on the circumference for the centering

accuracy. The difference between the maximum

and minimum measurement values must be 0.03

mm or less; and even within this range, you can

make adjustments to increase the centering

accuracy as much as possible.

Note: when measuring, rotate the coupling and

the motor shaft together.

Loading...

Loading...