Chapter 9 Troubleshooting ASDA-B2

9-6 Revision May, 2018

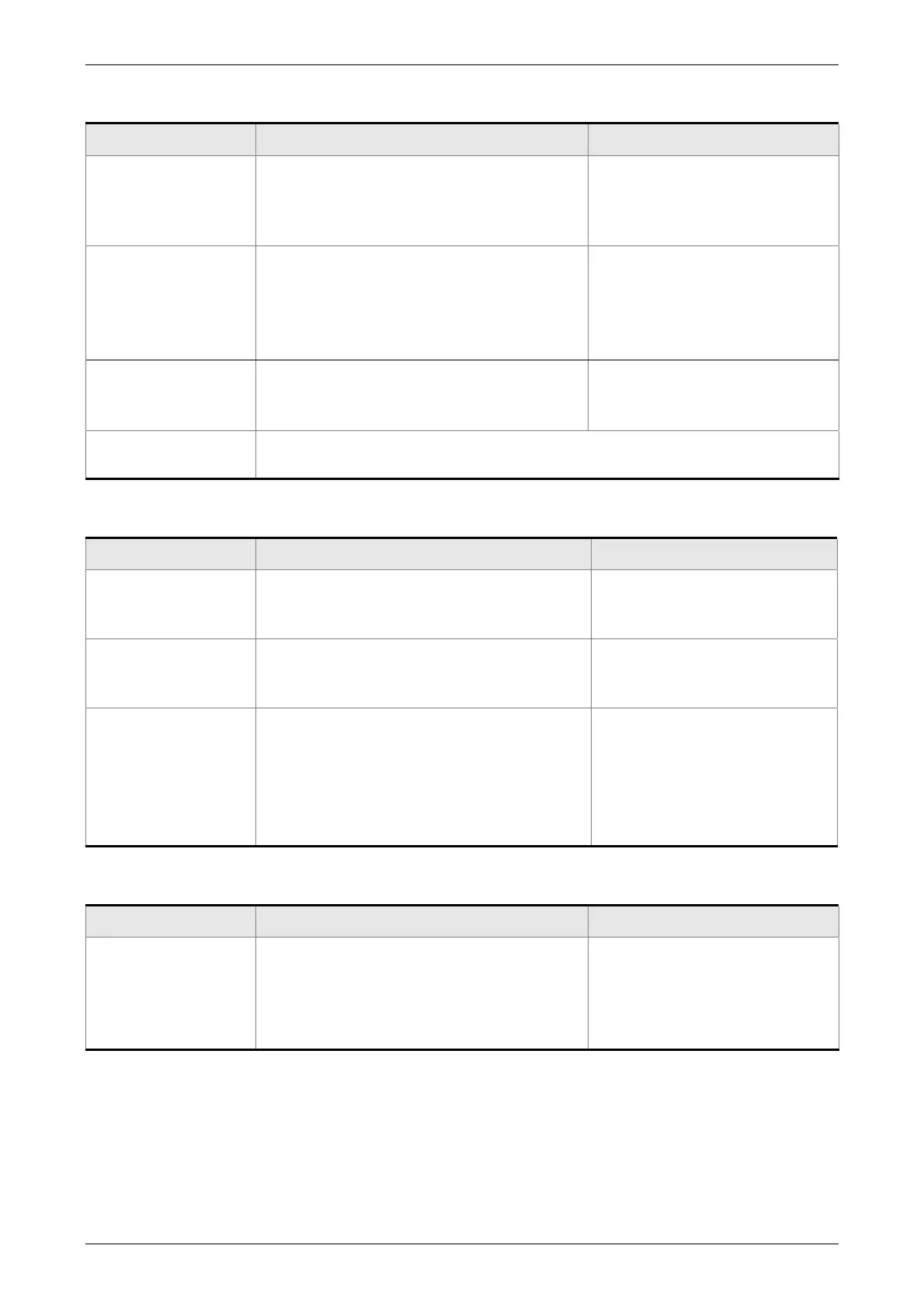

AL006: Overload

Causes Checking Method Corrective Actions

Over the rated

loading of the drive

and continuously

excessive using

Set parameter P0-02 to 11 and see if

the average torque [%] is over 100% all

the time.

Increase the motor capacity

or reduce the load.

The setting of the

control system

parameter is

inappropriate.

1. Check if there is any mechanical

vibration.

2. Check if the acceleration /

deceleration constant are set

too fast.

1. Adjust the gain value of

the control circuit.

2. Slow down the

acceleration /

deceleration setting time.

Wrong wiring of the

motor and the

encoder.

Check the wiring of U, V, W and the

encoder.

Correct wiring

The encoder of the

motor is defective.

Send the drive back to the distributors or contact Delta.

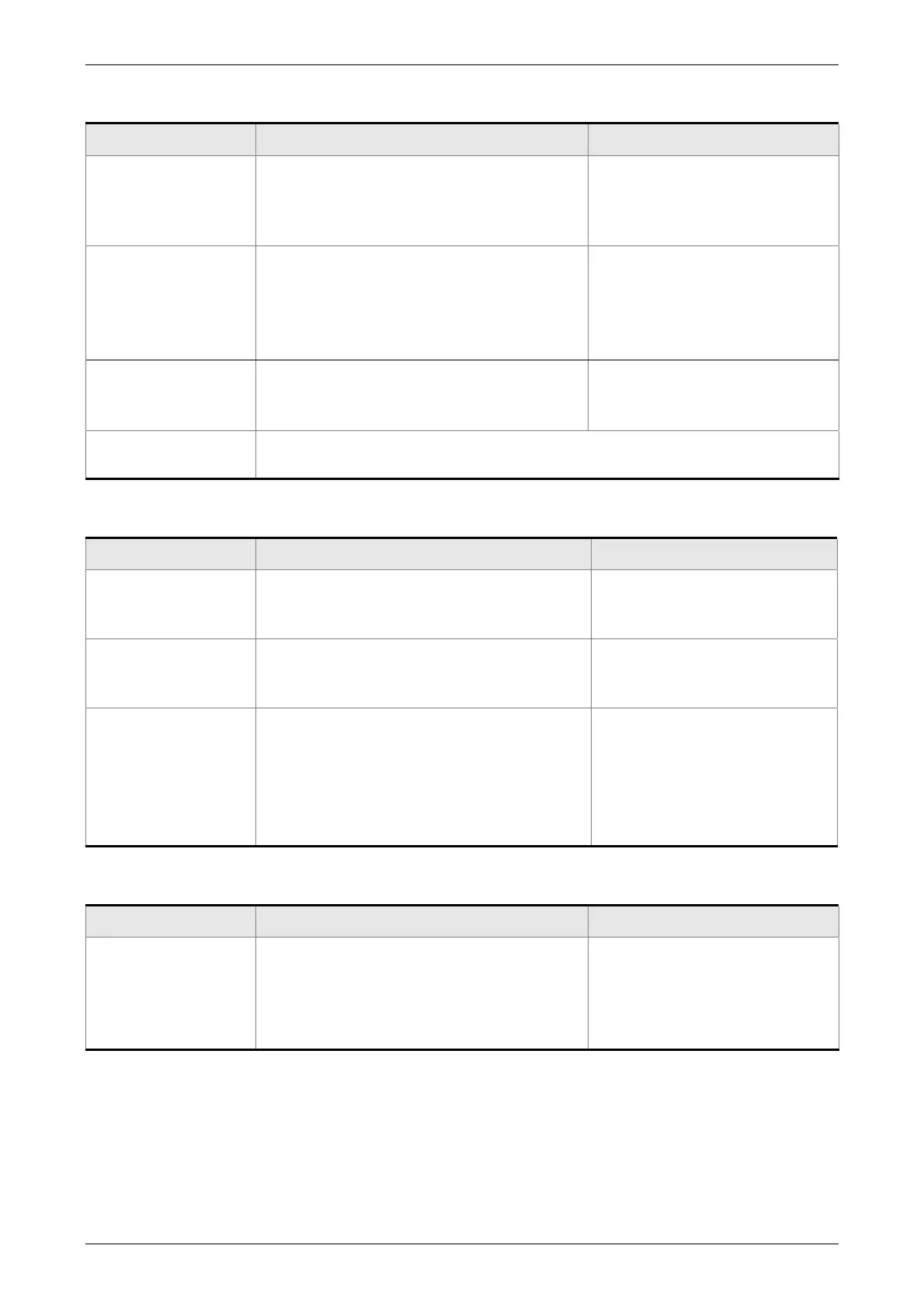

AL007: Overspeed

Causes Checking Method Corrective Actions

Unreasonable

command

Use the scope to check if the signal of

analog voltage is abnormal.

Less steep command used

or filter applying to smooth

command.

Inappropriate

parameter setting

Check if the setting of parameter P2-34

is too small (the condition of over-speed

warning).

Correctly set parameter

P2-34 (the condition of

over-speed warning).

Torque limit

1. Check if DI:TRQLM (torque limit) is

enabled.

2. Check if the torque limit default of

P1-02 is enabled.

3. Check if there is any torque limit

setting for P1-12 ~ P1-14.

1. Disable torque limit DI.

2. Disable the default

setting.

3. P1-12 ~ P1-14 = 100%

AL008: Abnormal pulse command

Causes Checking Method Corrective Actions

The pulse

command

frequency is higher

than the rated input

frequency.

Use the scope to check if the input

frequency is over the rated input

frequency.

Correctly set the input pulse

frequency.

Loading...

Loading...