50 Pictures for illustrating purposes only

ELECTROVAP MC2 STEAM BATH

Maintenance - Cleaning of steam cylinder

The ELMC steam generators are currently fitted with disposable

cylinder(s).The latter can however be easily substitued for cleanable

type at customer’s choice.

Drain the steam cylinder(s) fully using the manual drain key.

When the cylinder(s) is/are drained fully (a « DRAINING CYCLE

OVER » will appear on the display). Isolate the power both at the

general switchboard and at the humidifier (rocker power switch).

The steam cylinder(s) may be very hot. Allow it/them to cool down

before removing.

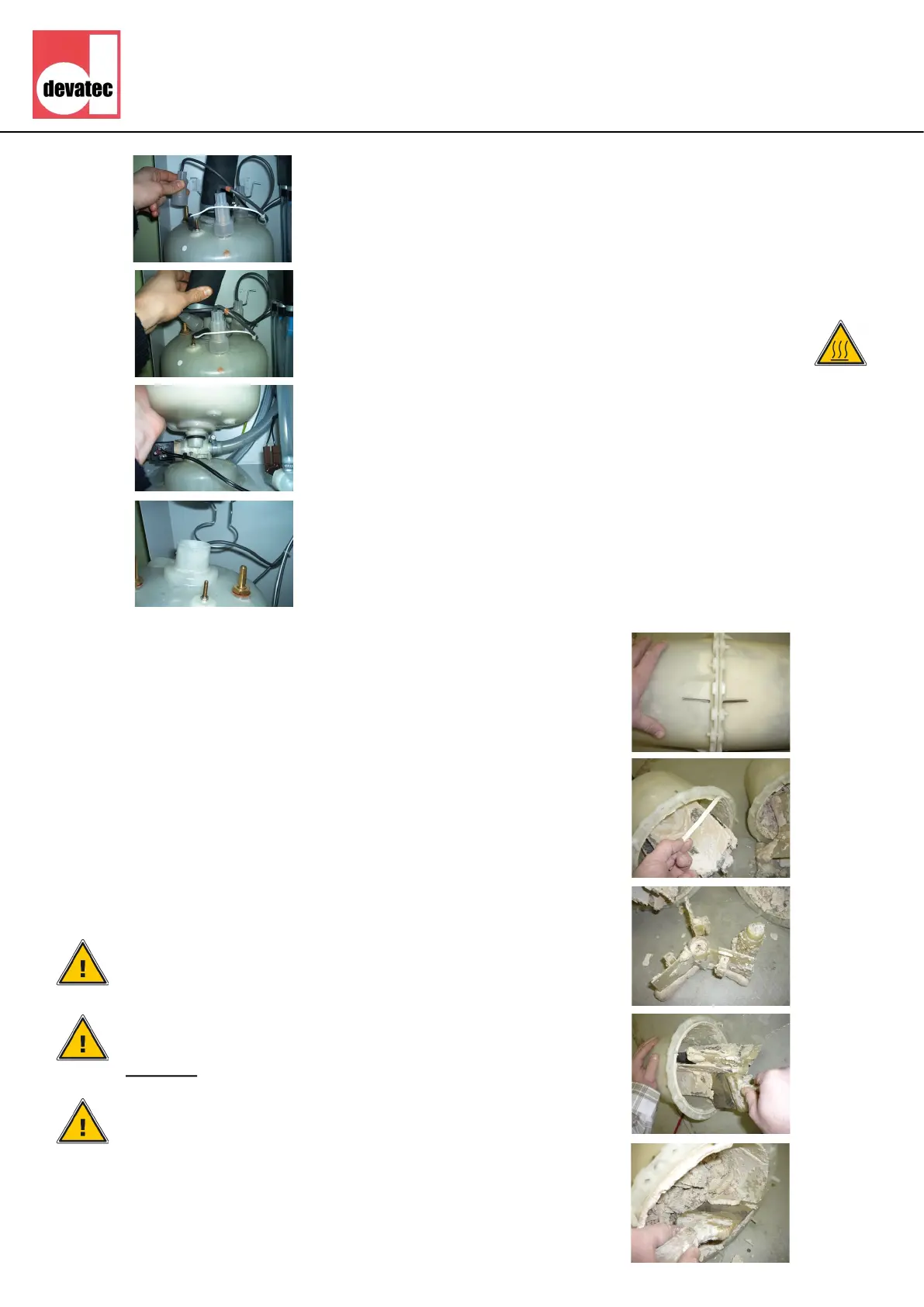

Remove the front panel from the generator to access the cylinder

compartment. Remove power and high water level electrode cables

from top of the cylinder(s) (picture 1).

Disconnect the steam hose(s) from the top of the cylinder(s) (pict. 2).

Lift the cylinder upwards until it is clear off the drain valve. Ensure that

the gasket remains in the drain valve (picture 3).

Release the top of the cylinder from the retaining clip and pull out the

cylinder (picture 4).

The disposable cylinder(s) will be merely replaced by new ones either

disposable or cleanable.

Retighten gently the steam hose on the cylinder outlet when the

cylinder has cooled down only to prevent deformation.

1.

2.

3.

4.

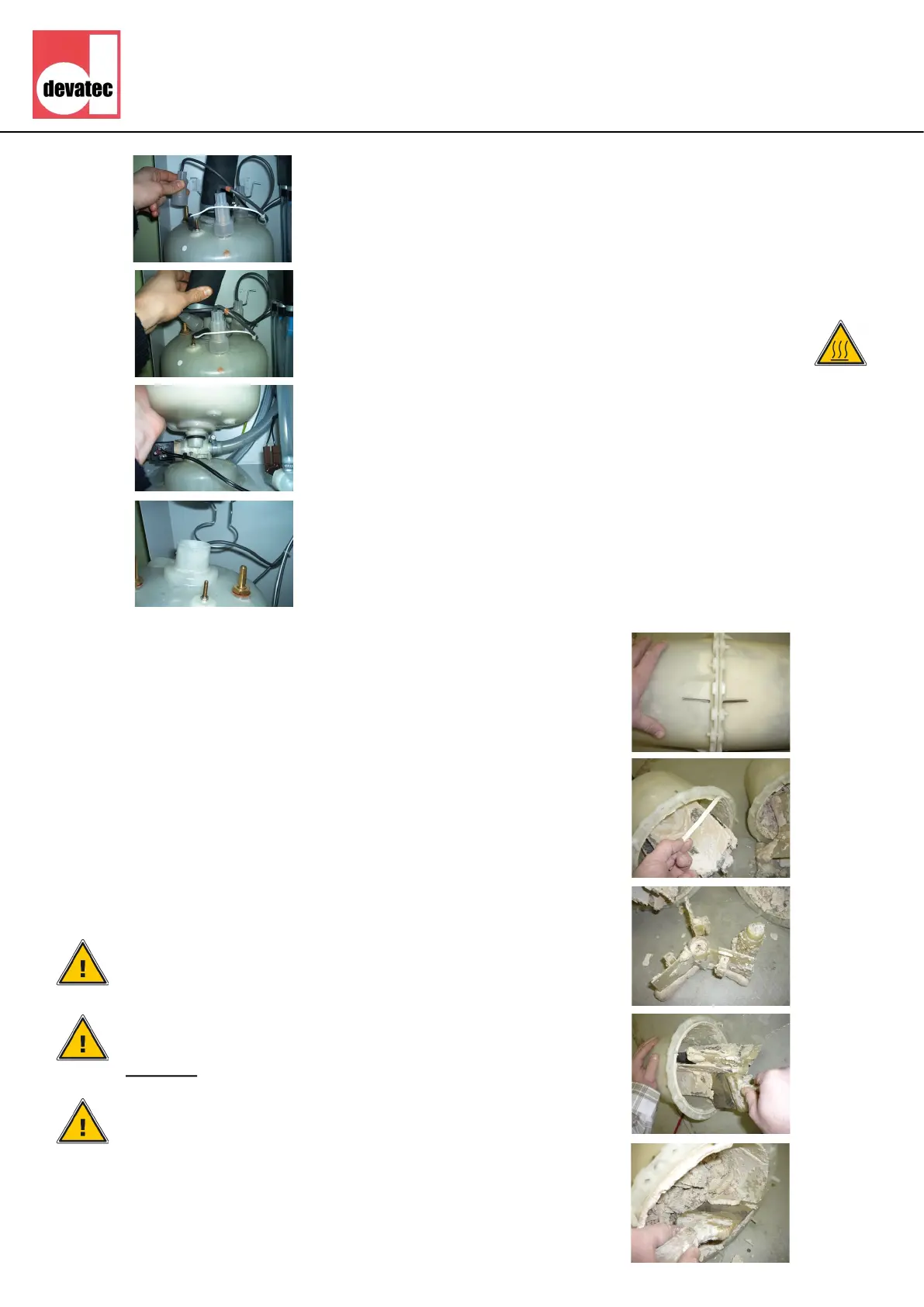

This method is intended for use with the cleanable cylinder only.

• Mark the edge of the cylinder halves so that they can be

matched up when reassembled (picture 5).

Remove the maintaining nuts and bolts, split the cylinder halves

and remove the gasket and the strainer that must be cleaned

(pict 6).

• Scrap mineral deposits off the electrode plates and the shells (a

weak descaling solution can also be used) (pictures 7, 8 & 9).

• Rince the electrodes, the cylinder shells and the divider. It is

important that the strainer at the cylinder bottom be also

cleaned.

Take care : never chock the shell rims to get rid of the deposits

Relocate the strainer into the cylinder bottom. Replace the cylinder

gasket, and fit it inside the groove of the lower shell and attach the

upper shell with the electrodes .

When re-assembling, take care to align both shells. Refit the bolts

and nuts. Retigthen them gently (when the cylinder is still cold). Rinse

the drain valve ‘o’ ring and grease it or replace it if needed.

Important

At this stage, the drain valve must be maintained.

NB : Refit the cylinder to the steam generator once the drain valve

is maintained.

5.

6.

7.

8.

9.

REPLACING THE STEAM CYLINDER

CLEANING THE CLEANABLE STEAM CYLINDER

Loading...

Loading...