Field Service Ver. 1.0 Apr. 2005 17. Image quality problem

153

ineo 161

ineo 210

Troubleshooting

17. Image quality problem

17.1 How to identify problematic part

• In this chapter, troubleshooting is divided into “initial checks” and “troubleshooting proce-

dures classified by image failures.”

• If any image failure has occurred, first make the initial checks, then proceed to the corre-

sponding image failure troubleshooting procedure.

17.1.1 Initial Check Items

• Determine if the failure is attributable to a basic cause or causes.

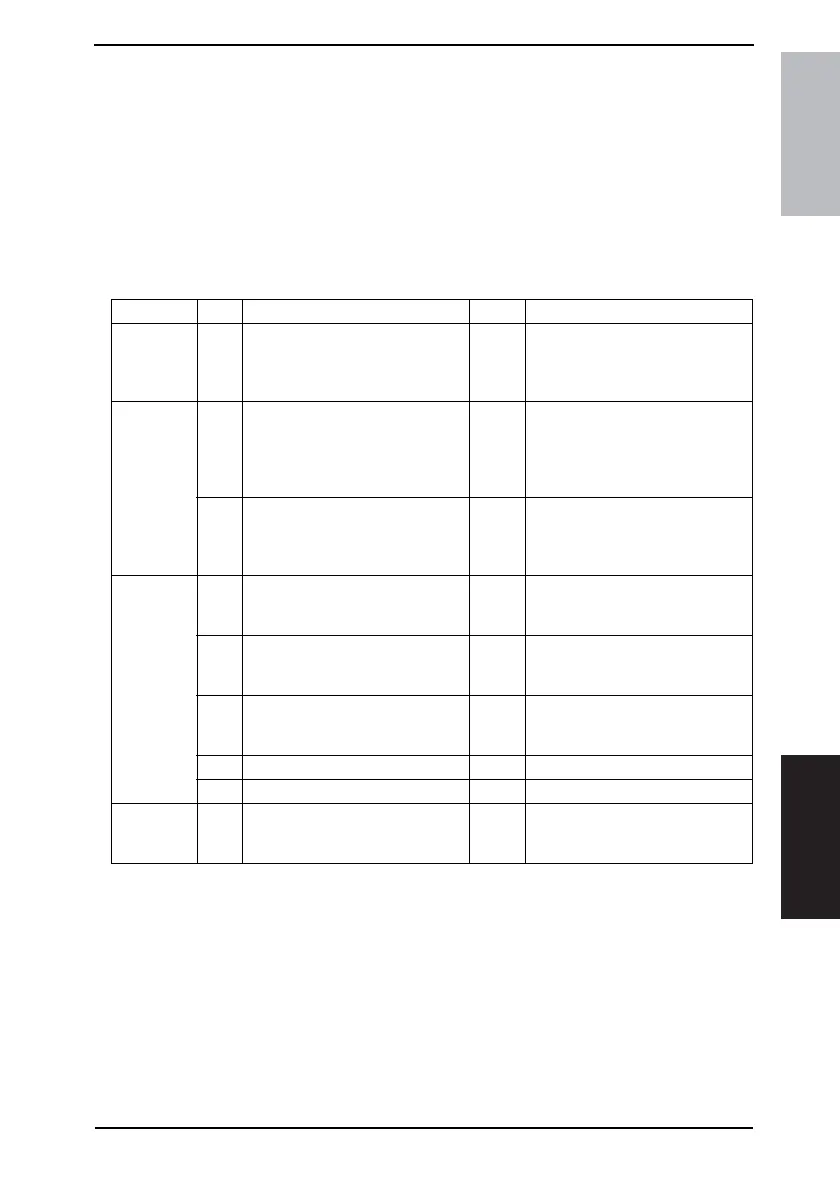

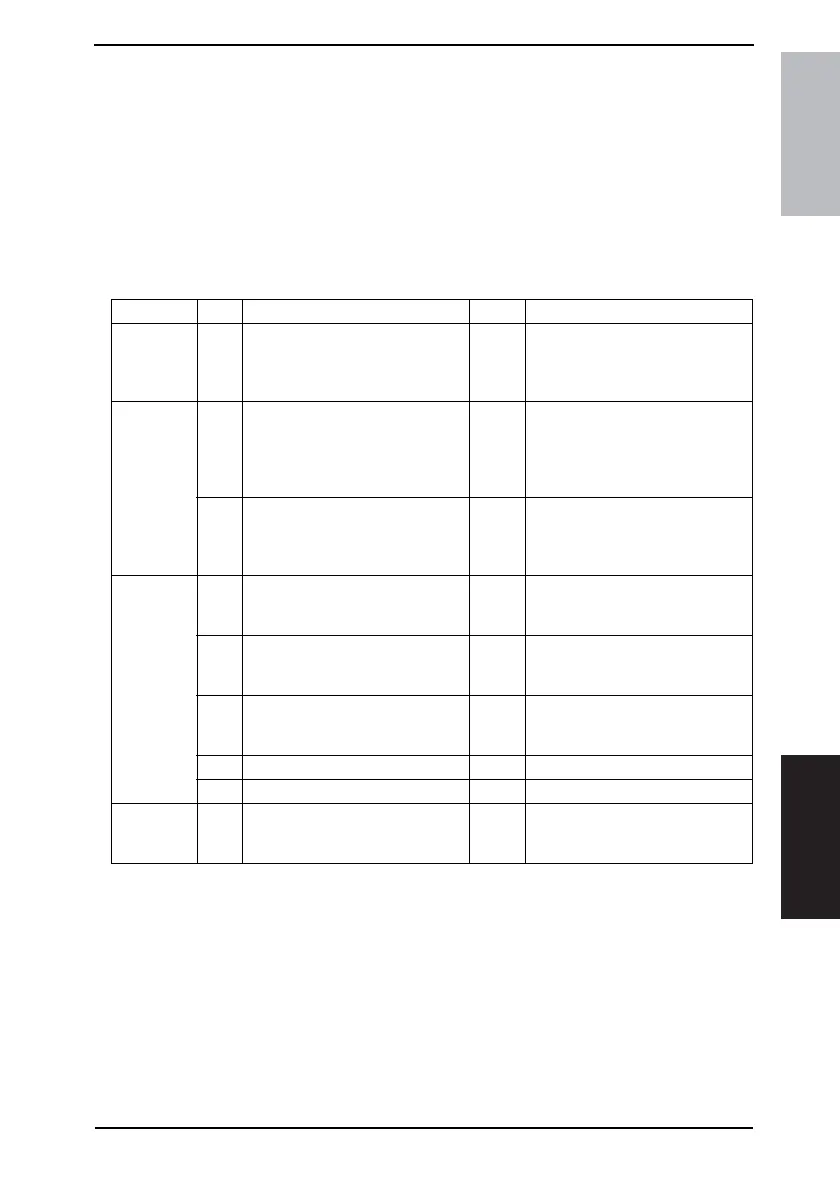

Section Step Check Result Action

Installation

site

1

The installation site complies with

the requirements specified in

“PRECAUTIONS FOR INSTALLA-

TION” contained in GENERAL.

NO • Change the installation site.

Paper

2

Paper meets product specifica-

tions.

NO

• Change paper for one that meets

specifications.

• Instruct user to use paper that

meets specifications and is rec-

ommended.

3 Paper is damp. YES

• Change paper for one that is dry.

Then, instruct user to use paper

that meets specifications and in

how to store paper.

Original

4 Original is placed correctly. NO

• Reposition original.

• Instruct user in how to place orig-

inal correctly.

5 Original is written in light pencil. YES

• Change original.

• Instruct user to use original with

appropriate image density.

6

Original is transparent (OHP film,

etc.).

YES

• Change original.

• Instruct user to use originals that

meet specifications.

7 Original Glass is dirty. YES • Clean Original Glass.

8 Original Glass is scratchy. YES • Change Original Glass.

PM parts 9

The PM parts relating to image for-

mation have reached the end of

cleaning/replacement cycles.

YES

• Clean PM parts.

• Change PM parts.

Loading...

Loading...