17. Image quality problem Field Service Ver. 1.0 Apr. 2005

168

ineo 161

ineo 210

Troubleshooting

17.2.14 Printer Section: Low image density

A. Typical Faulty Images

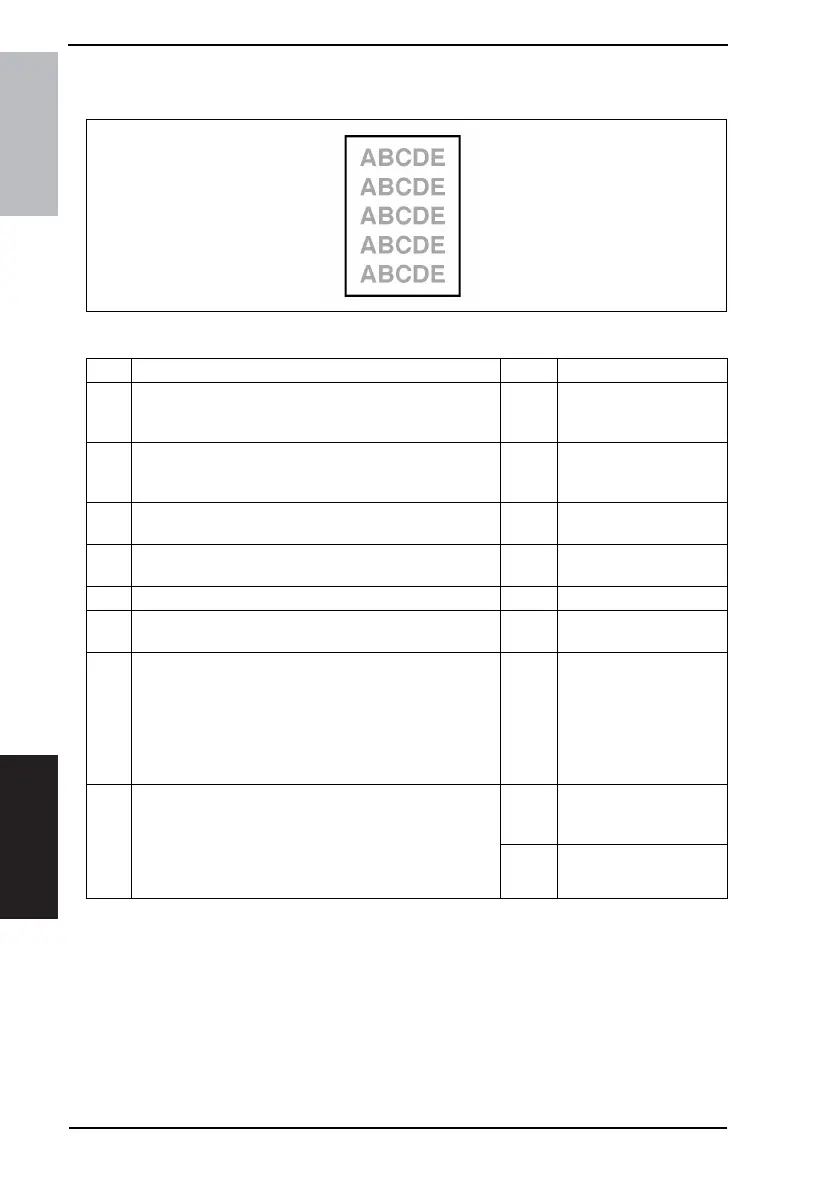

B. Troubleshooting Procedure

4011T003AA

Step Check Result Action

1

The image changes when “Toner Replenisher” is exe-

cuted.

• “Toner Replenisher” of Utility

YES

• Replenish the supply of

toner using Toner

Replenisher.

2

The image changes when “ID Adjust” and “VG Adjust” are

executed.

YES

• Readjust. For details,

see ADJUSTING/SET-

TING.

3 Image transfer current contact is dirty, folded, or bent. YES

• Clean, correct, or

change.

4 Developing bias contact is dirty, folded, or bent. YES

• Clean, correct, or

change.

5 High Voltage Unit (HV1) connectors is loose. YES • Reconnect.

6

ATDC Sensor (UN1) is dirty with foreign matter (such as

paper dust) other than developer.

YES • Clean.

7

The following voltages develop from the ATDC Sensor

(UN1).

<Check Procedure>

Check voltage across a Master Board pin and GND when

the Power Switch is turned ON.

• DC5.39 V to 8.15 V across PJ10A-1 and GND

• DC1.41 V to 4.98 V across PJ10A-3 and GND

NO

• Change ATDC Sensor

(UN1) and then change

developer.

8

The following voltage is supplied from the Master Board

(PWB-A).

<Check procedure>

• Check that there is 24 V developing across the Master

Board pin and GND when the Power Switch is turned

ON (during a copy cycle or a standby state).

YES

• Change IU.

• Change High Voltage

Unit (HV1).

NO

• Change Master Board

(copier: PWB-A).

Loading...

Loading...