D439E Service Manual 2. Engine Mechanical System (D439E)

79

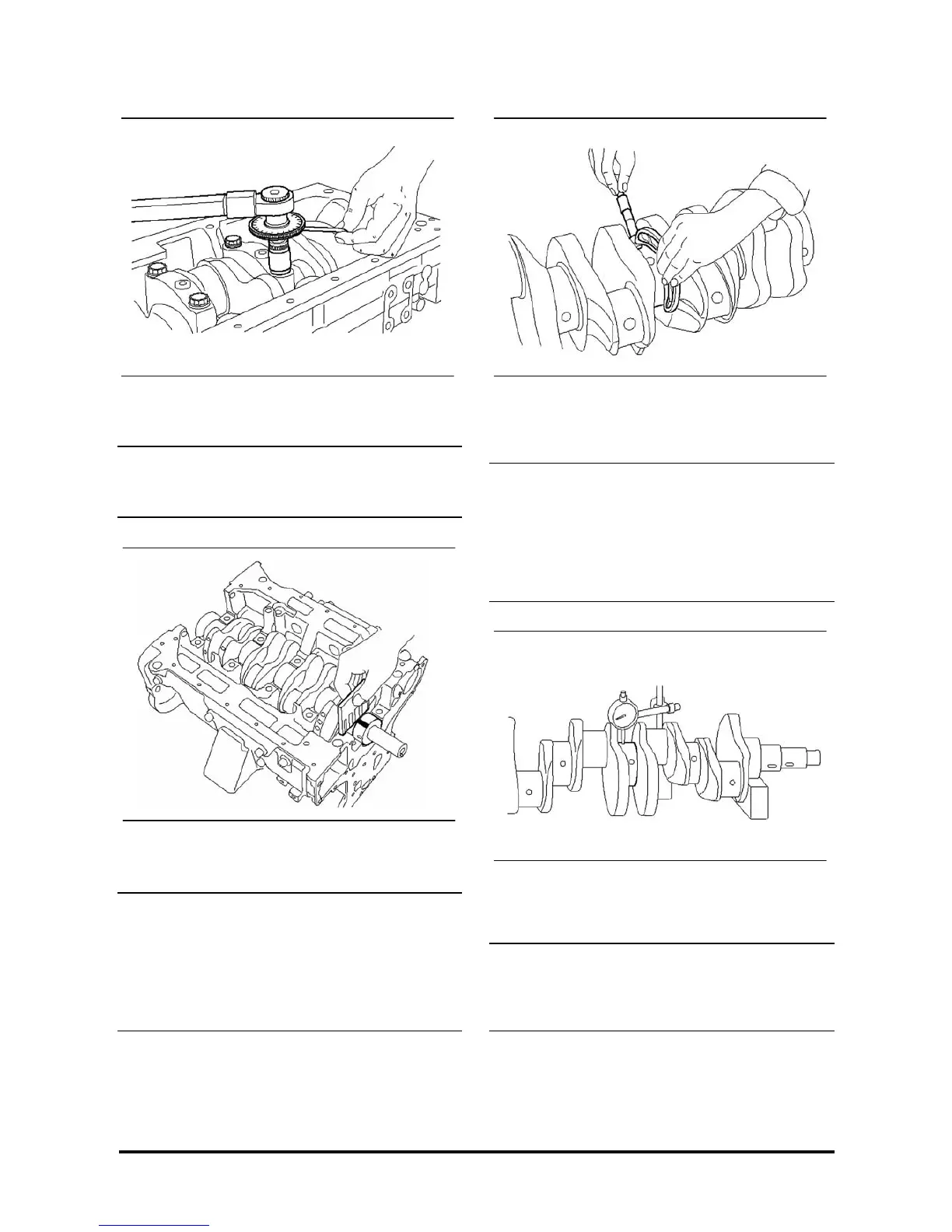

3) Install the main bearing cap and fasten the

bolt.

Tightening torque : 49.0 Nm + 90°

(5.0 kgf.m + 90°, 36.4 Ib-ft + 90°)

4) Remove the main bearing cap and measure

oil gap at each journal.

Oil gap of journal #1, 2, 4 and 5

Reference : 0.036 ~ 0.098 mm

Limit : 0.15 mm

Oil gap of journal #3

Reference : 0.056 ~ 0.118 mm

Limit : 0.15 mm

5) If the oil gap of the main bearing is

excessively large, replace the main bearing.

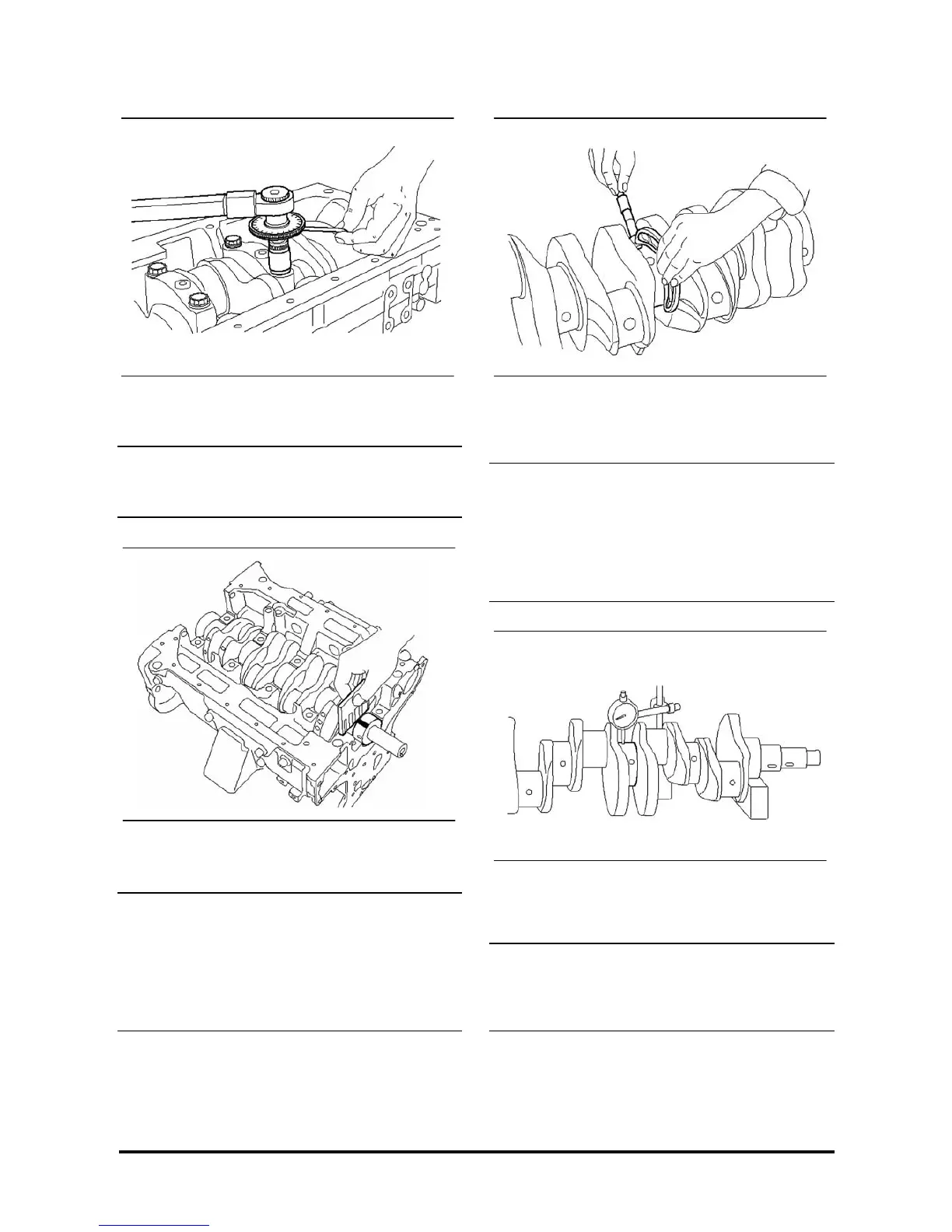

3. Measure roundness and cylindricity of crankshaft

journal and pin. If the measurement exceeds the

limit, repair it with under size.

Roundness of crankshaft

Reference : less than 0.01 mm

Limit : 0.03 mm

Cylindricity of crankshaft

Reference : less than 0.006 mm

Limit : 0.03 mm

4. Check to see if the crankshaft is bent.

Install the dial gauge of crankshaft center journal,

and check the bending of the crankshaft.

Bending of the crankshaft

Standard : Below 0.02 mm

Limit : 0.05 mm

NOTE : Actual bending is a half of the measurement.

Loading...

Loading...