MINUTEMAN 320

82

REV 13.1:2020

5.5 Pusher Drive Belt Adjustment

Caution bar feeder and lathe must be emergency stop for belt

adjustment

Warning properly trained personnel are required to adjust drive belt

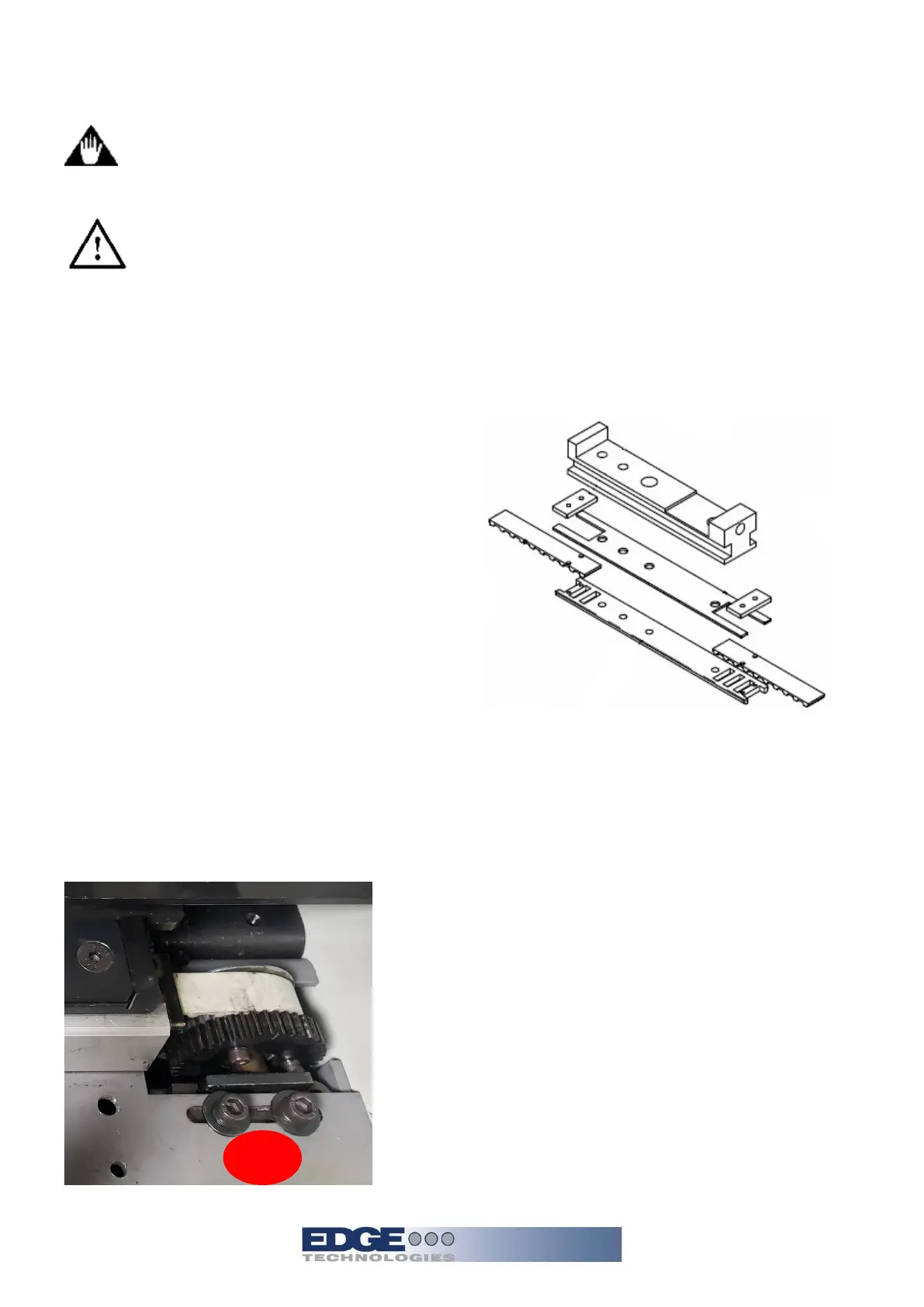

The pusher drive belt is connected to the carriage. The belt runs the length of the machine

contained inside of a channel. The belt is driven by a servo drive motor via gear reduction

system opposite of the lathe for adequate torque production.

If belt replacement required be sure the carriage

mounting screws and holes are clean and dry of

any oils. A medium thread lock is required.

Anytime the drive belt requires adjustment follow the procedure below.

1. Place bar feeder and lathe into emergency stop.

2. Material may need to be removed form channel if the pusher cannot be moved without

obstruction.

3. Open bar feeder hood.

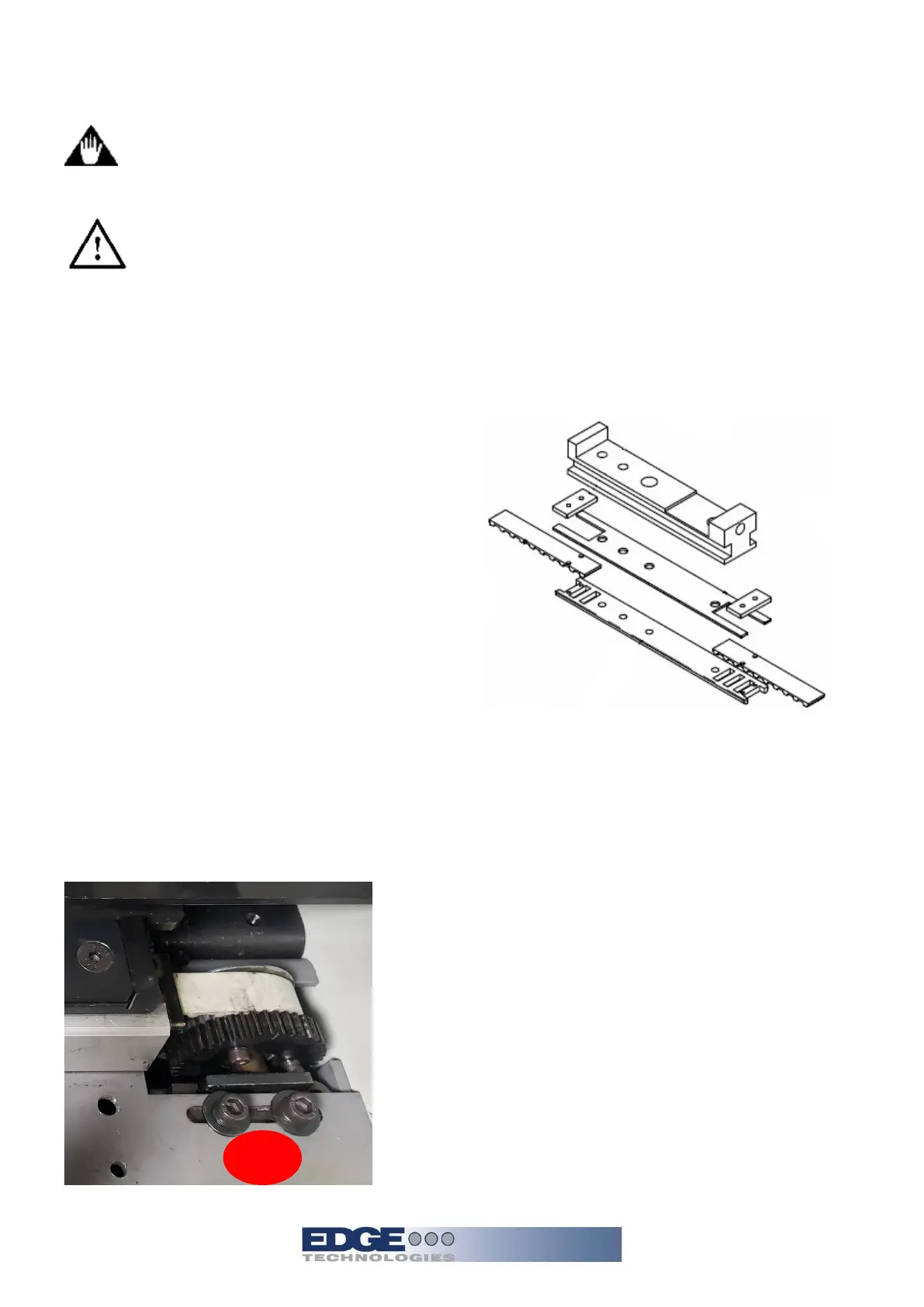

4. Loosen the 2 locking screws (1) for the

tensioner.

5. Move the motor assembly to the desired

tension. Warning do not set belt tension

too tight, as this will stretch the belt and

potentially lead to belt failure.

6. Tighten the locking screws (1).

7. Close the bar feeder hood.

8. Reset emergency stops and test pusher

operation with the hand held pendant.

Loading...

Loading...