- AB620A5035 Instruction Manual

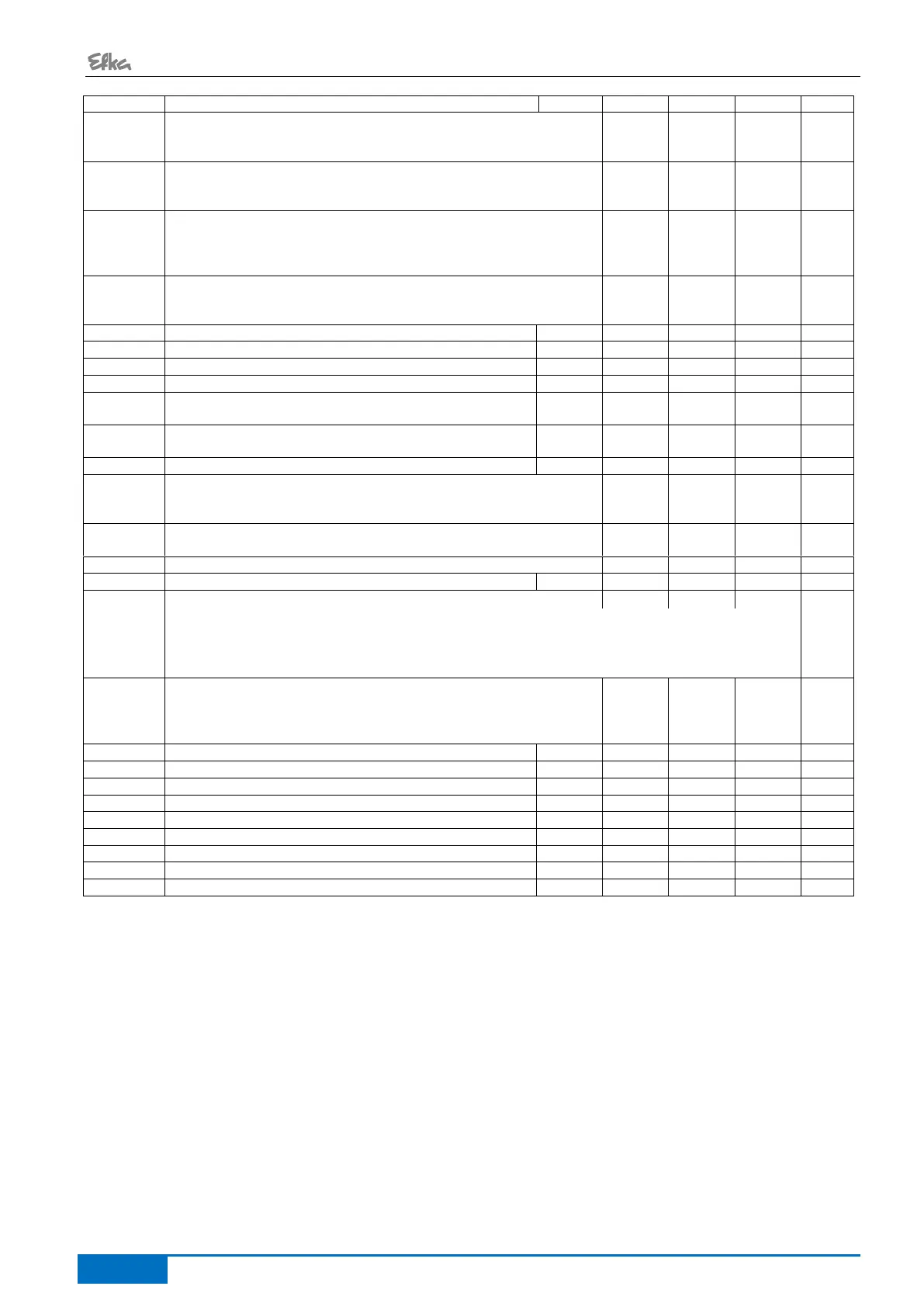

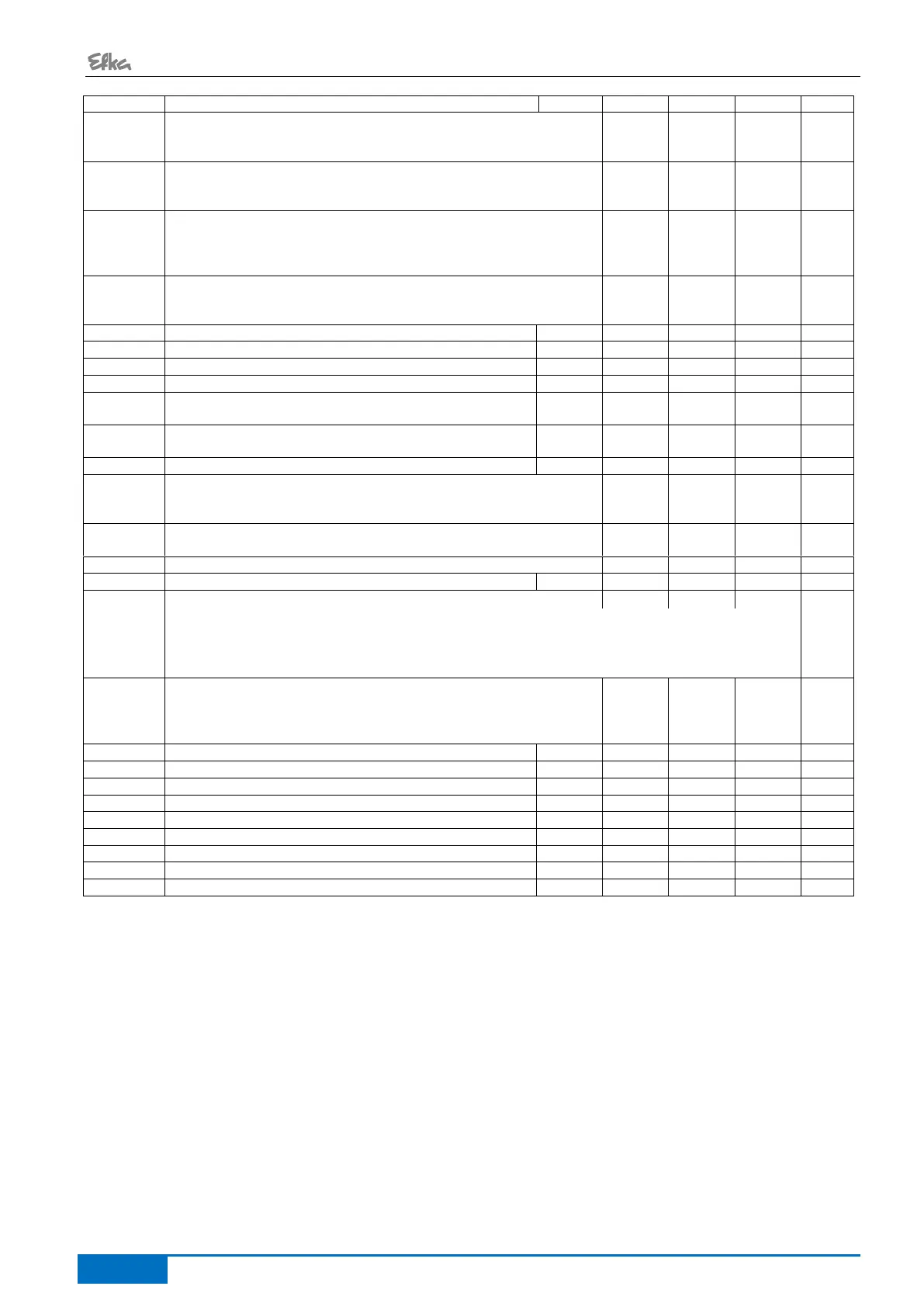

Selection of input function on socket ST2/8 for input 4

0 = No function

All other functions of the keys as with parameter 240

Selection of input function on socket ST2/5 for input 5

0 = No function

All other functions of the keys as with parameter 240

Selection of input function on socket ST2/12 for input 6

0 = No function

All other functions of the keys as with parameter 240

Selection of input function on socket ST2/9 for input 7

0 = No function

All other functions of the keys as with parameter 240

Thread trimmer activation angle

Switch-off start backtack of thread tension release

Switch-on start backtack angle of thread tension release

Stopping time for thread trimming

Upper limit (Pa.204) clocking the sewing foot lifting switch

on period (ED) 1...100 %

Upper limit (Pa.213) clocking the sewing foot on period

(ED) 1...100 %1...100

Activation start backtack angle of the thread trimmer

0 = Signal “high lift for walking foot”, when key is closed.

1 = Signal “high lift for walking foot”, when key is open. (Function

only if parameter 137 = 1)

Overlock mode: Interrupt the start count

And seam end initiation by light barrier uncovered

Speed limitation via "select". (F290=55 & F290=74)

0 = No external sensor. Positions are created via the sensor integrated in the motor.

5 = No position sensor available. The drive stops unpositioned. The thread trimmer function is

suppressed with this setting.

6 = With external sensor (e.g. IPG, HSM...).

Transmission ratio between motor shaft and machine shaft

(calculation formula see instruction manual!)

The transmission ratio should be determined and indicated as

precisely as possible!

Start backtack time output M1

Start backtack time output M2

Start backtack time output M3

Start backtack time output M4

Start backtack time until sewing foot On

Loading...

Loading...