22

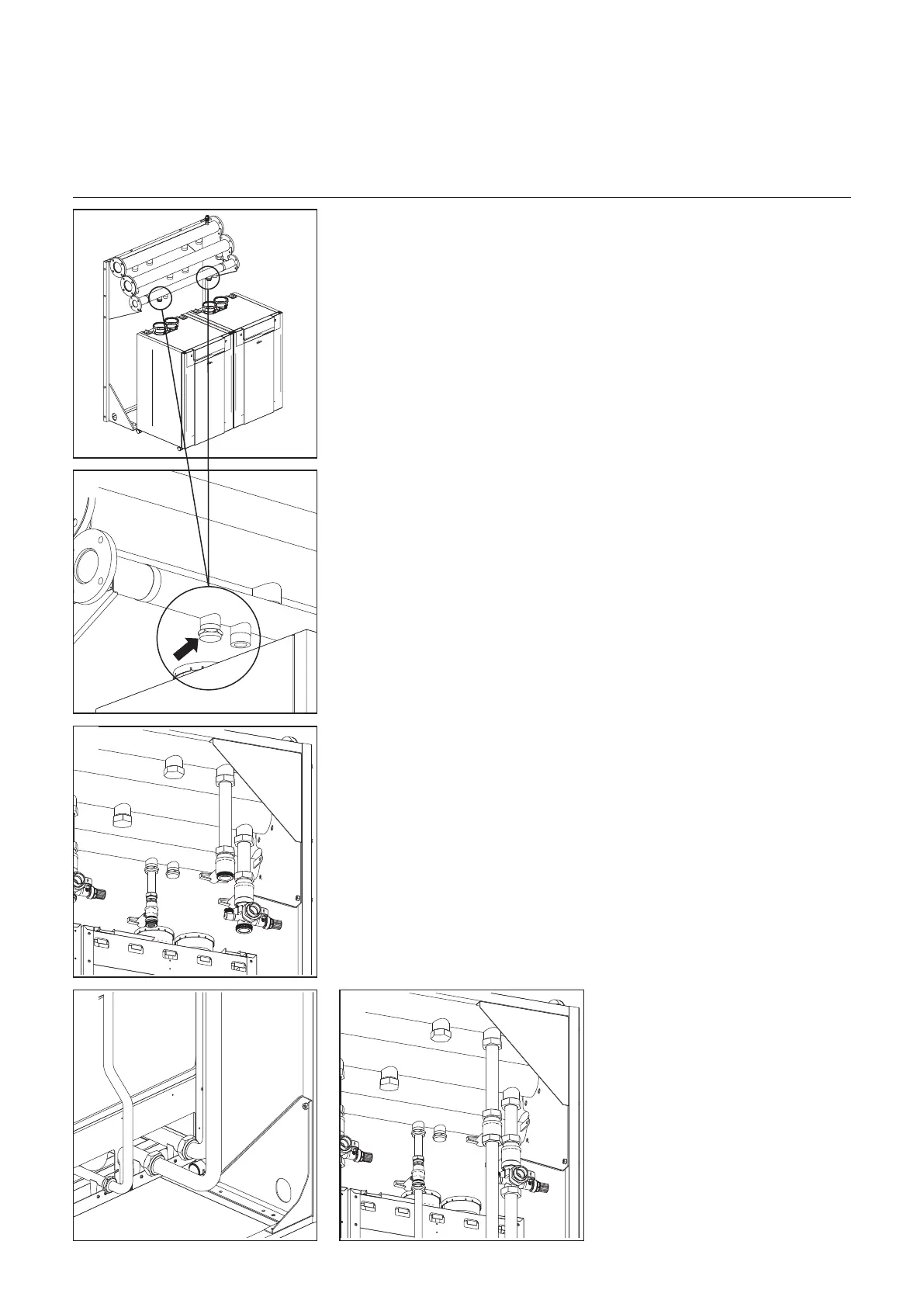

Installation

Connecting the boiler

1-2. Keep the cap on the connections

that are not used on the pipe work

headers:

Flowandreturn:2"blindcapwith

gasket(2items/boiler).

Gas:1¼"blindcapwithgasket

(1item/boiler).

For connections, use the supplied

gaskets. Check all connections for

leakage and gas-tightness.

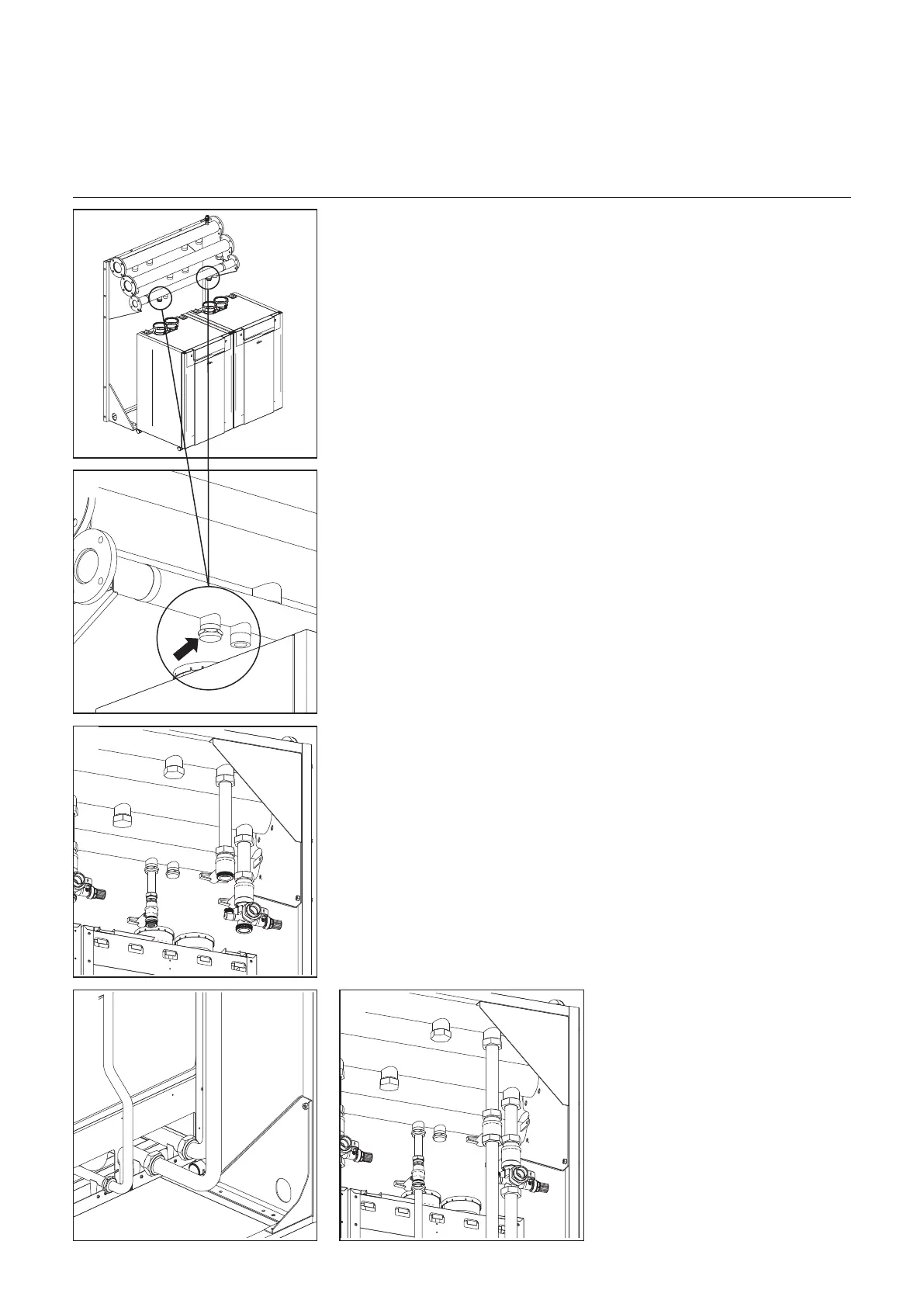

3. Connect the valves to the pipe work

headers:

Flow:45mmpipepieceswith2"at

coupling,2"atcouplingisolation

valve with red handle.

Return: 45mm pipe pieces with 2"

atcoupling,2"atcouplingtting

crossunionwithll/drainvalveand

isolationvalvewithbluehandle.

Theboilerissuppliedwitha3and

6barsafetyvalve.

ELCOrecommendttingthe

6barsafetyvalveduetothecontrol

settingsshuttingtheboileroat

6bar.

Gas: 28mm short gas pipe with

11/4"atsealingand28mm

compressionttingwith1¼"gas

isolation valve.

Polluted test water may be released

when removing the plastic caps on

the boiler ow and return.

For connections, use the supplied

gaskets. Check all connections for

leakage and gas-tightness.

4. Connectthepipestotheboiler:

Flow:45mmpipepieceswith2"at

coupling.

Return: 45mm pipe pieces with

2"atcoupling.

Gas:28mmpipepiecewith1¼"at

coupling.

5. Connect the pipes to the valves

Flow: 45mm pipe pieces with

2"atcoupling.

Return: 45mm pipe pieces with 2"

atcoupling.

Gas:28mmpipepiecewith1¼"at

coupling.

For connections, use the supplied

gaskets. Check all connections for

leakage and gas-tightness.

1

2

3

4 5

Loading...

Loading...