85

Maintenance

Decommissioning and maintenance works

Inspection and maintenance interval

Boiler maintenance is only to be

carried out by qualied sta with

calibrated equipment.

When replacing spare parts only

original ELCO Service parts are to

be used. For this purpose, please

refer to the Service parts list to nd

article numbers and exploded views.

Please contact ELCO.

Maintenance intervals

Maintenancehastobecarriedoutat

least after 16,000 operational hours

max. or every 4 years, whatever comes

rst.(To verify with local

service depending by installing

condition).

Depending on the intensive use of

the device, maintenance intervals will

havetobedecreasedaccordingly.For

other situations, maintenance intervals

mayalsohavetobedecreased.In

such cases, please contact ELCO for

additional advice.

Inspection and maintenance tasks

havetobecarriedoutinaccordance

with the maintenance instructions at

alltimes.Sometasksaredescribedin

these maintenance instructions. For

complete inspection and maintenance

instructions, see pages 87-93.

When carrying out maintenance

on the boiler, the gas tap has to be

closed and secured against opening.

Maintenance works

- Use the ON/OFF switch (A) to turn

theboilero;

- Interrupt the power supply to the

boiler,byoperatingthemainscircuit

breakerintheboilerroom.

- Interruptthegassupplytotheboiler.

Duringemptyingoftheboiler,itis

possiblethatapartoftheheating

waterstaysbehind.Makesurethat

any remaining heating water cannot

freeze, in case of a frost hazard.

Decommissioning

Itmaybenecessarytosettheboiler

out of service in some situations.

Switchtheboilerto“o” mode (white

colorofpowerbutton)pressingthe

powerbutton.

ThisswitchesothefunctionsDHW

prog and Pump prog respectively.

ELCO recommends leaving the power

switch switched on to ensure that the

boilerpump(s)andthree-wayvalve

(iftted)areautomaticallyactivatedto

prevent them from sticking. The frost

protection remains active. Leave gas

supply open.

If frost, during the period when the

boiler is out of operation, is likely,

then you are advised to remove the

power from the boiler and drain the

boiler(s) and installation. In this

case: close the gas valve.

Maintenance

Pleaseobservethefollowingsafety

instructions:

All works on the boiler and

the heating facility (assembly,

maintenance, repairs) may only

be carried out by authorized

technicians, by using suitable

tools and calibrated measuring

instruments. The exchange of

components requires original

ELCO replacement parts.

Themainstopcockforgasmustbe

closed and secured against reopening.

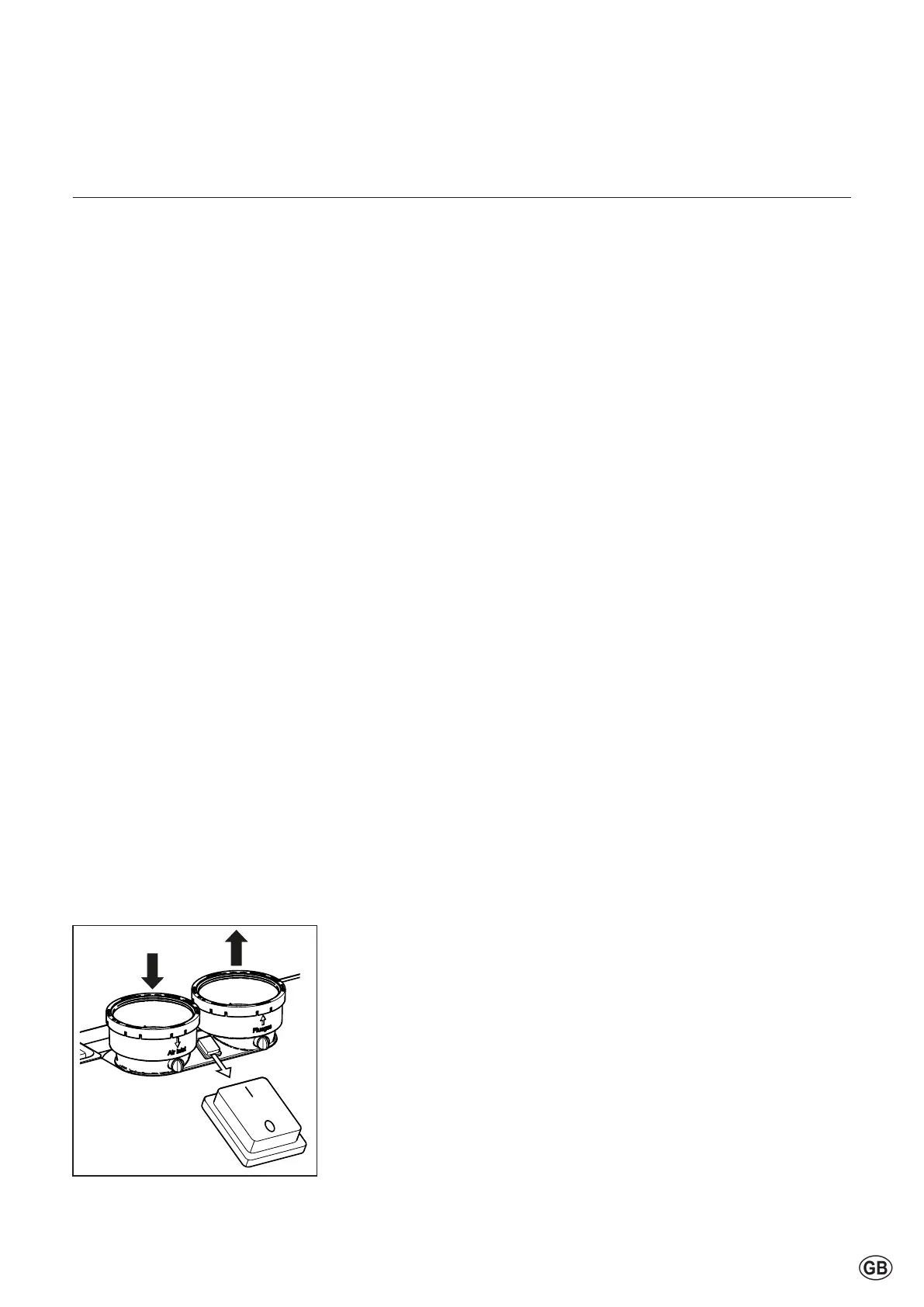

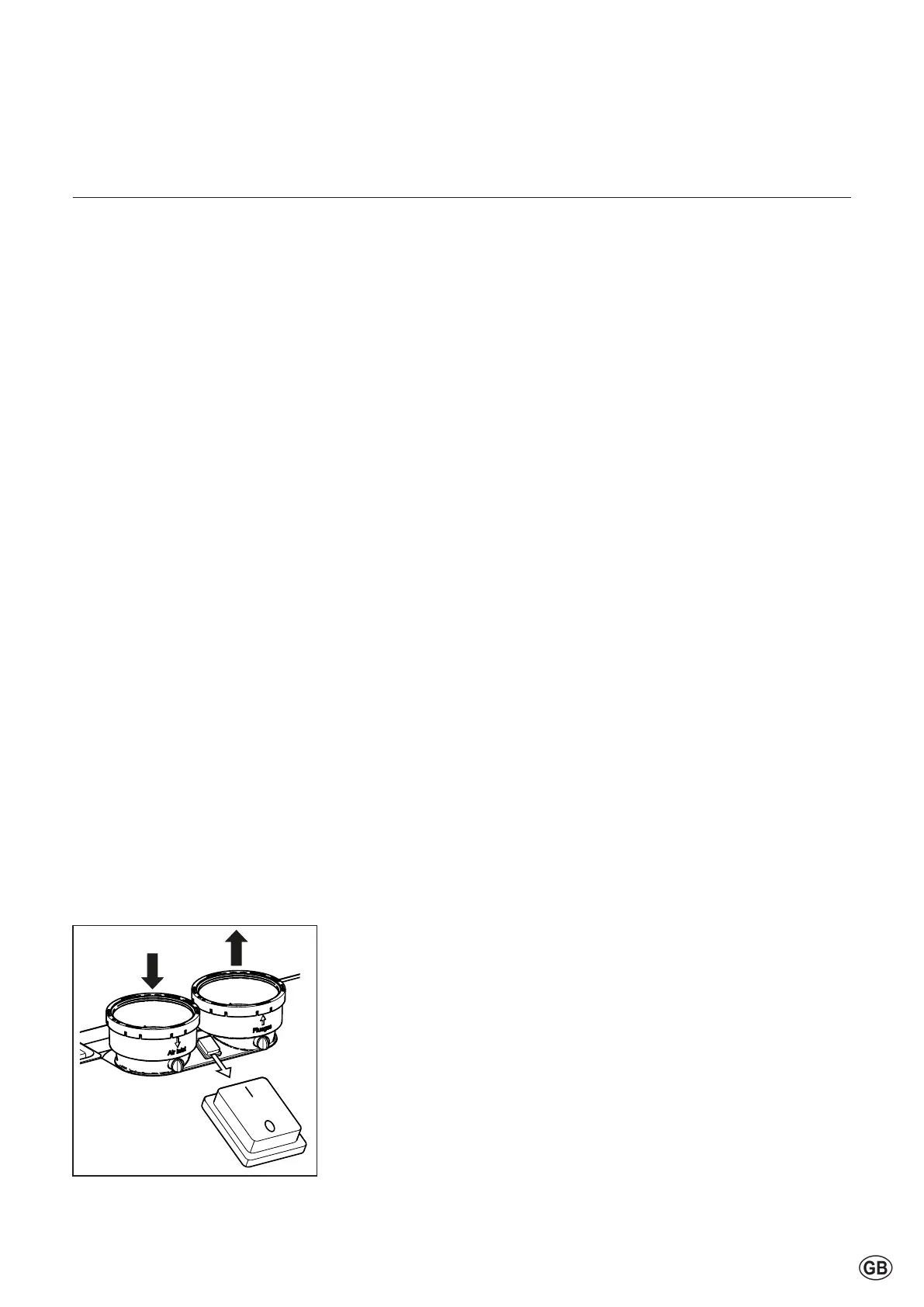

Thecasingmustrstberemoved,

tobeabletocarryoutmaintenance

ontheboiler.Thepanelissecured

by2screwsontopofthedoor.

After loosening the screw, the casing

canberemovedbypullingandliftingit.

Follow instruction on page 82.

All equipment is preset at the factory.

An O

2

/ CO

2

control measurement must

becarriedoutduringcommissioning.

Nochangeshouldbemadeonthe

zero-point setting. The zero-point

settingmustonlybecheckedafter

a malfunction, or after an exchange

of the gas valve, the venturi or the

ventilator motor.

The zero-point setting does not

serve for setting up the combustion-

technical characteristic values.

These are made exclusively through

the O

2

/ CO

2

setting.

All gas pipes and screws must be

tested for leakproofness, using

a leak-detecting spray, whenever

maintenance or repair works have

been carried out on the boiler.

Inthisregard,pleaseobserveallof

the individual maintenance steps

documentedonpage90.,aswell

as the overview of inspection and

maintenance procedures provided on

page 92 to 93.

Inspection interval

An inspection must be carried out

at least after every 4,000 boiler

operating hours, however at least

once every year. (To verify with local

service depending by installing

condition).

An inspection consists of a visual

check, of the general condition of the

boilerandtheinstallation.

Theobjectivesofaninspectionisan

assessment of the condition of the

equipment, and an evaluation as to

when maintenance works are required.

A visual inspection can lead to a

maintenance procedure.

No tools are required during an

inspection (except for tools for

removing the panelling). If necessary,

the corresponding individual

maintenancestepsmustbecarriedout,

which are listed as of page 93.

A

Loading...

Loading...