33

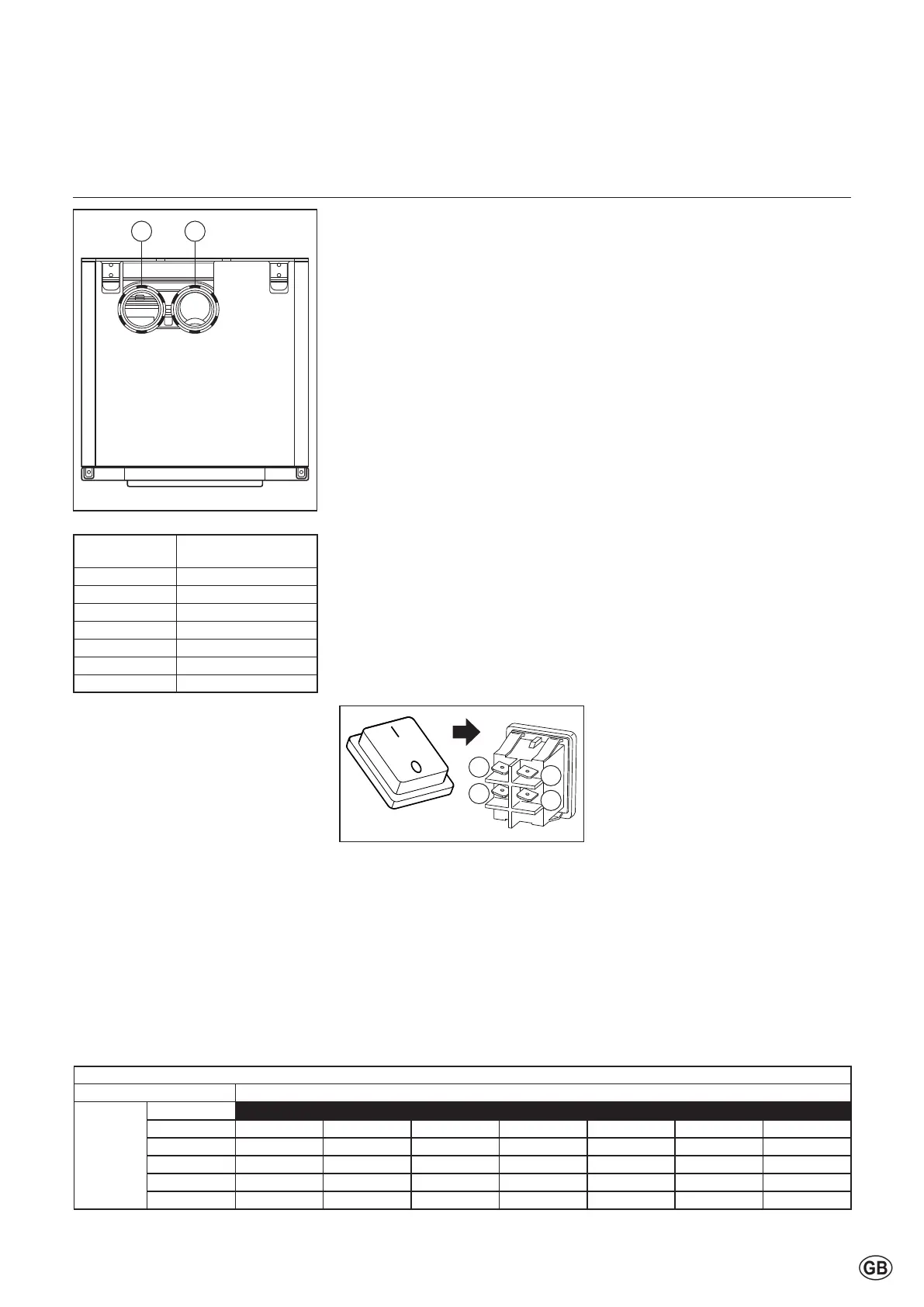

Parallel boiler connection

Theboilercomesasstandardwitha

parallelconnectionfortheuegas

outlet and air supply system.

For the air supply opening (1) diameter

andtheuegasoutletconnection(2),

seetablebelow.

Theairsupplychannelcanbe

connected to it, or, if it involves an

“open device” (Drainage category B),

anairlterisrecommended.

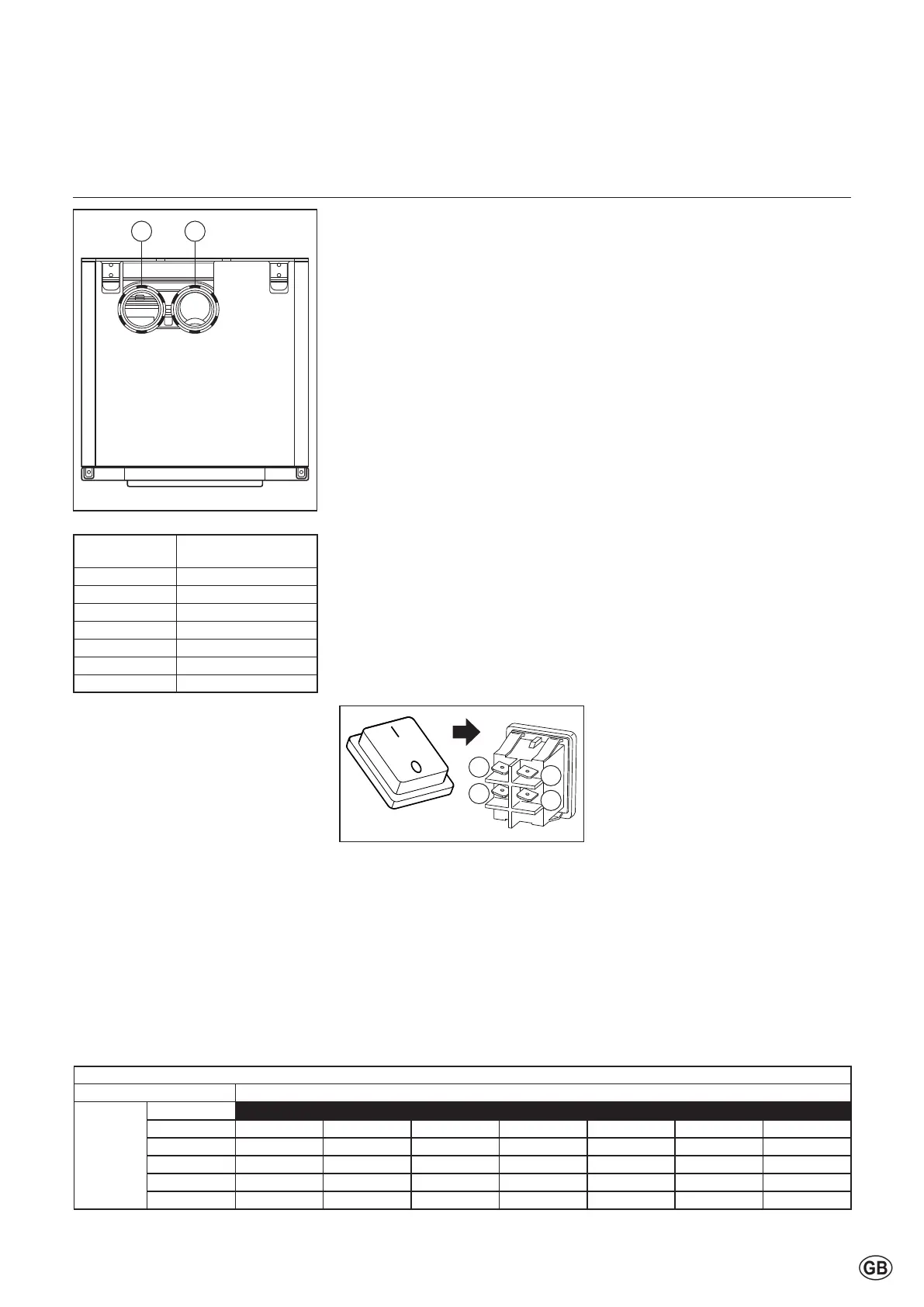

Concentric boiler connection

Theboilers60-70-100-120-140canbe

converted into a concentric connection

using the parallel/concentric adapter

100/150 (optional) and carrying out the

following tasks:

- Open and remove the frontal

panel and the top panel (follow the

instruction on page 42.

- Lift the parallel connection.

- Disconnect the main switch 230V

connection and remove it.

- Replace the parallel connection

with parallel concentric adapter.

- Connectandtthemainswitch

230V according to previous

conguration.

The air supply opening has a diameter

of ø150mm.

Theuegasoutletconnectionhasa

diameter of ø100mm.

Theuegasoutlet-/airsupplysystem

is then connected to the concentric

connection component.

Installation

Connections

Air- / ue gas ducts for individual boilers

TheTRIGONLPLUS-boilerscanbe

usedbothinan“open”andin“closed”

system.

Open system

Therequiredcombustionairistaken

from the immediate environment

(boilerroom).Forthispurpose,please

complywiththeapplicableboilerroom

ventilation regulations.

WhenusingboilercategoryB23and

B33asan‘openboiler’,theprotection

degreeoftheboilerwillbeIPX0D

instead of IPX4D.

Anairlteroragridisrecommended

ontheairintakeoftheboiler(available

as an accessory on pages 15-17.

Closed system

Therequiredcombustionairissucked

in from the outside through a channel.

Thisimprovesinstallationpossibilities

withinabuilding.Ingeneral,outsideair

iscleanerthanairfromtheboilerroom.

When the boiler is op erational,

it produces a white plume of

condensation. This condensation

plume is harmless but may cause

some inconvenience, particularly

in the case of wall terminal. As a

result, roof terminals are preferred.

In a closed installation, roof

terminals should be at the same

height preventing ue gas from

being sucked in by the other boiler

(recirculation). Outlets in recesses

and near erected walls may also

bring about ue gas recirculation.

Recirculation has to be prevented at

all times.

For installation in UK please refer to

installation guidance in BS6644 and

IGE UP10.

Boiler type Air duct - ue gas

diameter

60 100 - 100

70 100 - 100

100 100 - 100

120 100 - 100

140 100 - 100

170 130 - 130

200 130 - 130

21

2

4

1

3

Fan settings correction

By setting parameter (21-2-4) it is

possibletocompensateforahigher

uegaspressuredierence.Itis

required to have a pressure drop

calculationoftheapplieduegas

system.

According the calculated pressure

drop, the correct value for parameter

(21-2-4)hastobechosenfromthe

tablebelow.

For setting parameters see the

applicablechapter.

Flue Gas System pressure drop

Boiler type

Parameter

(21-2-4)

60 70 100 120 140 170 200

0 - 600 161 156 243 143 200 215 265

700 189 204 295 177 230 280 321

800 226 224 350 207 275 313 370

900 250 250 405 240 300 375 -

1000 278 278 457 260 304 375 -

Loading...

Loading...