Rosemount Model 8800C Vortex Flowmeter

2-12

Flanged-Style

Flowmeter Mounting

Physical mounting of a flanged-style flowmeter is similar to installing a

typical section of pipe. Conventional tools, equipment, and accessories

(such as bolts and gaskets) are required. Tighten the nuts following the

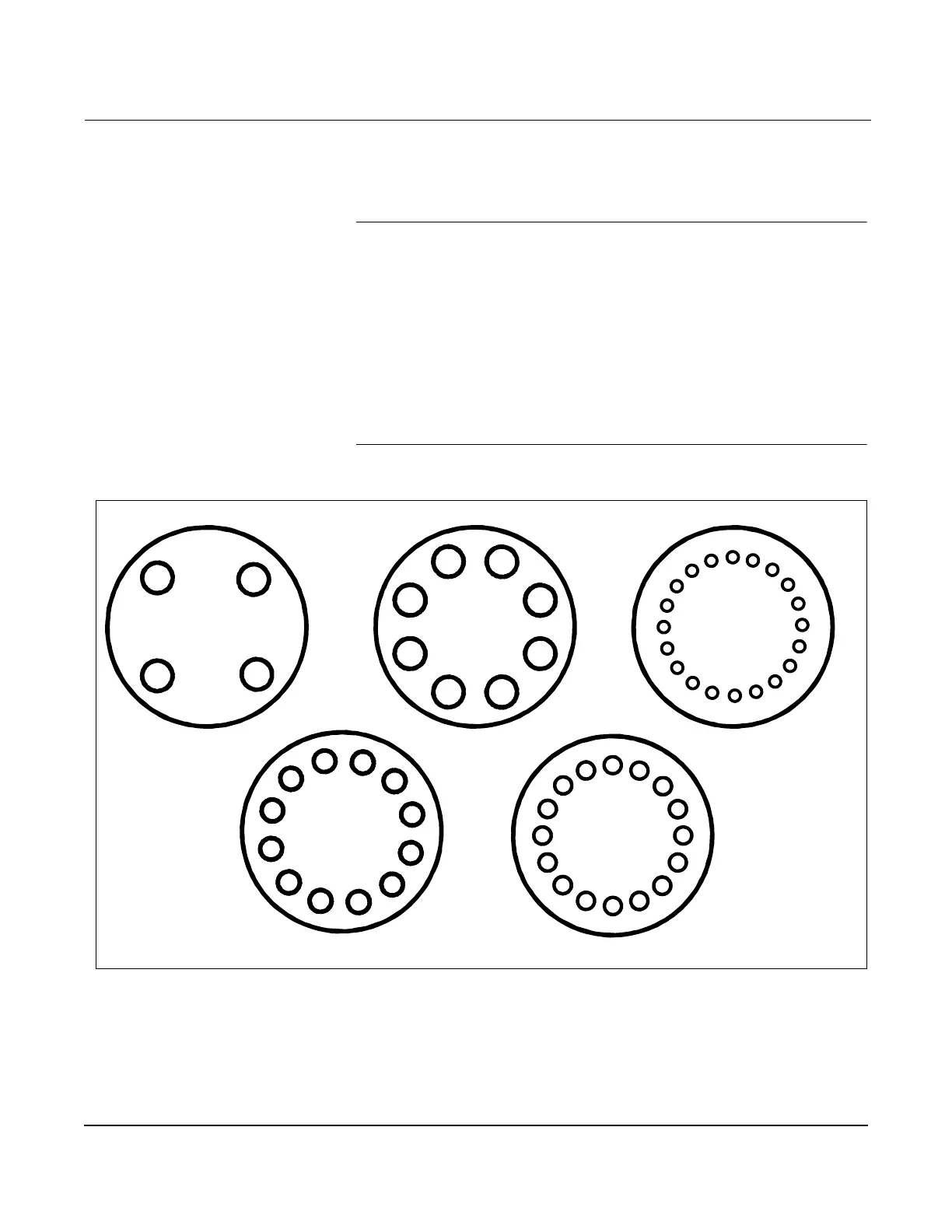

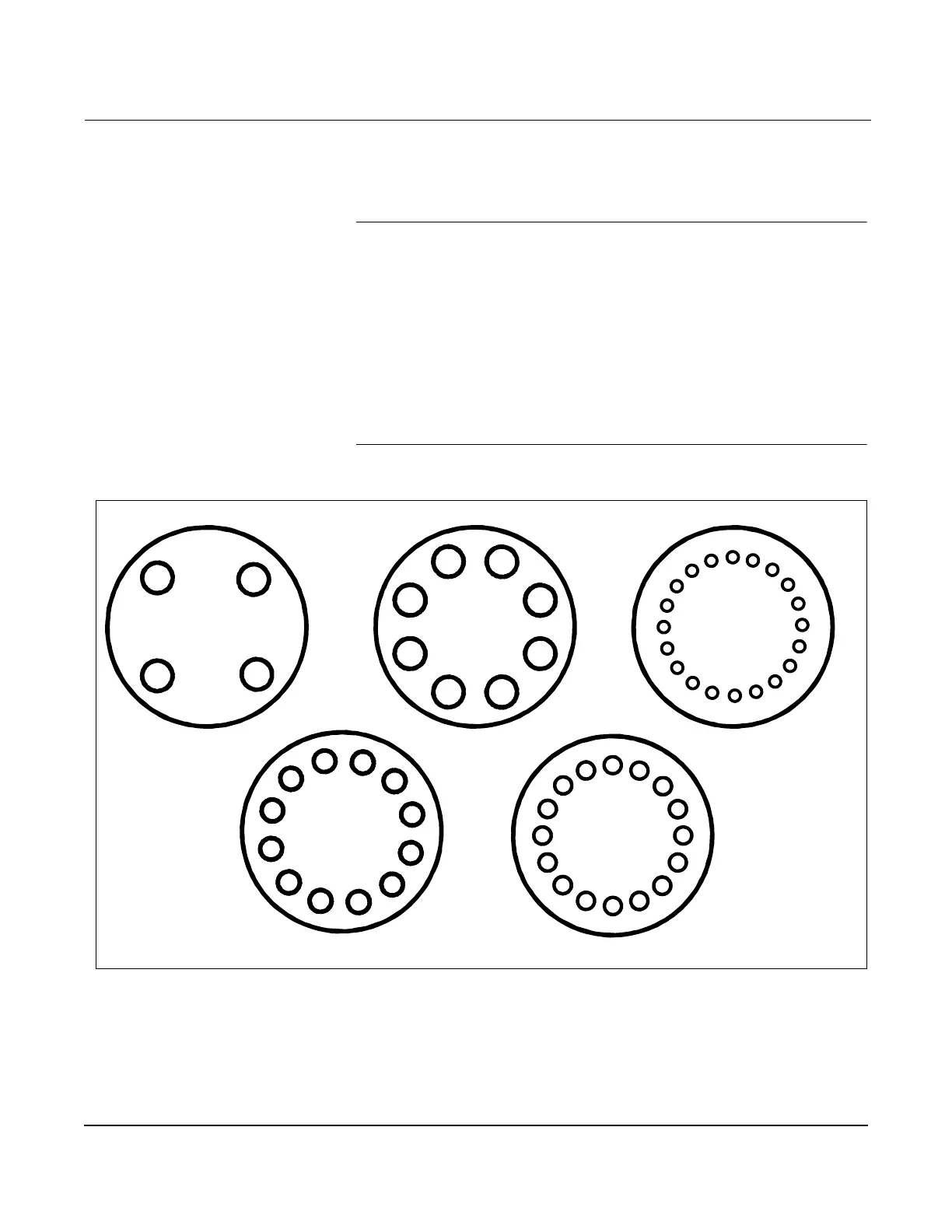

sequence shown in Figure 2-9.

NOTE

The required bolt load for sealing the gasket joint is affected by several

factors, including operating pressure and gasket material, width, and

condition. A number of factors also affect the actual bolt load resulting

from a measured torque, including condition of bolt threads, friction

between the nut head and the flange, and parallelism of the flanges. Due

to these application-dependent factors, the required torque for each

application may be different. Follow the guidelines outlined in the ASME

Pressure Vessel Code (Section VIII, Division 2) for proper bolt tightening.

Make sure the flowmeter is centered between flanges of the same

nominal size as the flowmeter.

Figure 2-9. Flange Bolt Torquing Sequence

8800-0088A

1

3

4

2

3

8

1

5

2

7

6

4

14

18

9

1

9

5

11

3

19

15

7

13

17

2

10

6

12

4

20

16

8

3

7

2

6

10

4

8

12

1

5

16

1

9

5

11

3

13

7

15

2

10

6

12

4

14

8

16-Bolt

12-Bolt

8-Bolt

4-Bolt

20-Bolt

11

Loading...

Loading...