Installation Proline Promass E 100 Modbus RS485

22 Endress+Hauser

Sanitary compatibility

When installing in hygienic applications, please refer to the information in the

"Certificates and approvals/hygienic compatibility" section → 99

Rupture disk

Information that is relevant to the process: → 93.

L

WARNING

Danger from medium escaping!

Medium escaping under pressure can cause injury or material damage.

‣

Take precautions to prevent danger to persons and damage if the rupture disk is

actuated.

‣

Observe information on the rupture disk sticker.

‣

Make sure that the function and operation of the rupture disk is not impeded through

the installation of the device.

‣

Do not use a heating jacket.

‣

Do not remove or damage the rupture disk.

‣

After the rupture disk is actuated, do not operate the measuring device any more.

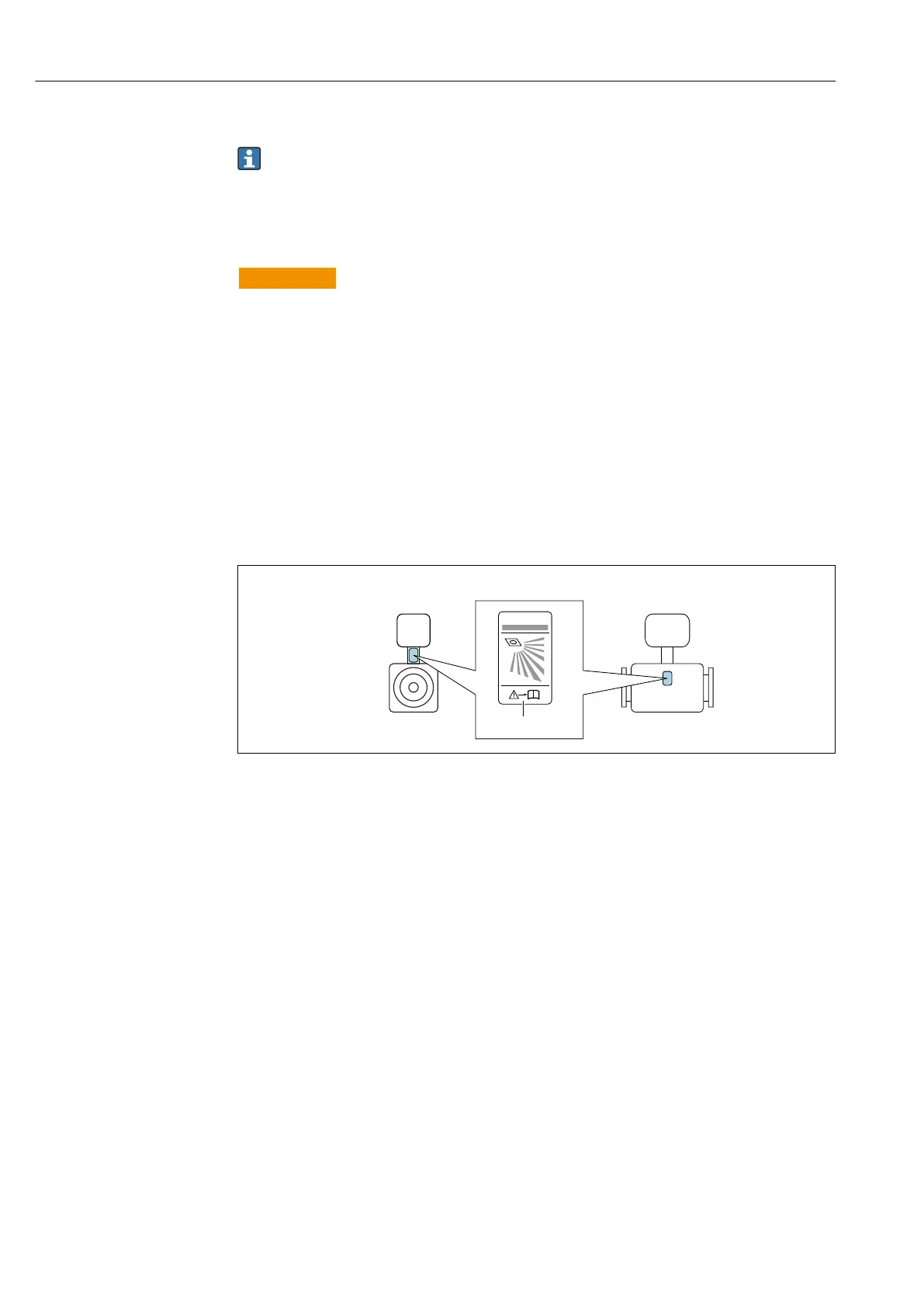

The position of the rupture disk is indicated on a sticker applied over it. If the rupture disk

is triggered, the sticker is destroyed. The disk can therefore be visually monitored.

RUPTURE DISK

i

1

DN 8 ( ")... ( ")!⁄# 50 2 DN ( ")80 3

A0029956

1 Rupture disk label

Zero point adjustment

All measuring devices are calibrated in accordance with state-of-the-art technology.

Calibration takes place under reference conditions→ 87. Therefore, a zero point

adjustment in the field is generally not required.

Experience shows that zero point adjustment is advisable only in special cases:

• To achieve maximum measuring accuracy even with low flow rates.

• Under extreme process or operating conditions (e.g. very high process temperatures or

very high-viscosity fluids).

6.2 Mounting the measuring device

6.2.1 Required tools

For sensor

For flanges and other process connections: Corresponding mounting tools

Loading...

Loading...