Commissioning Proline Promass E 100 Modbus RS485

56 Endress+Hauser

10.3.5 Configuring the partial filled pipe detection

The Partially filled pipe detection submenu contains parameters that have to be set for

configuring empty pipe detection.

Navigation path

"Setup" menu → Partial filled pipe detection

Structure of the submenu

Partially filled pipe detection

→

Assign process variable

Low value partial filled pipe detection

High value partial filled pipe detection

Response time part. filled pipe detect.

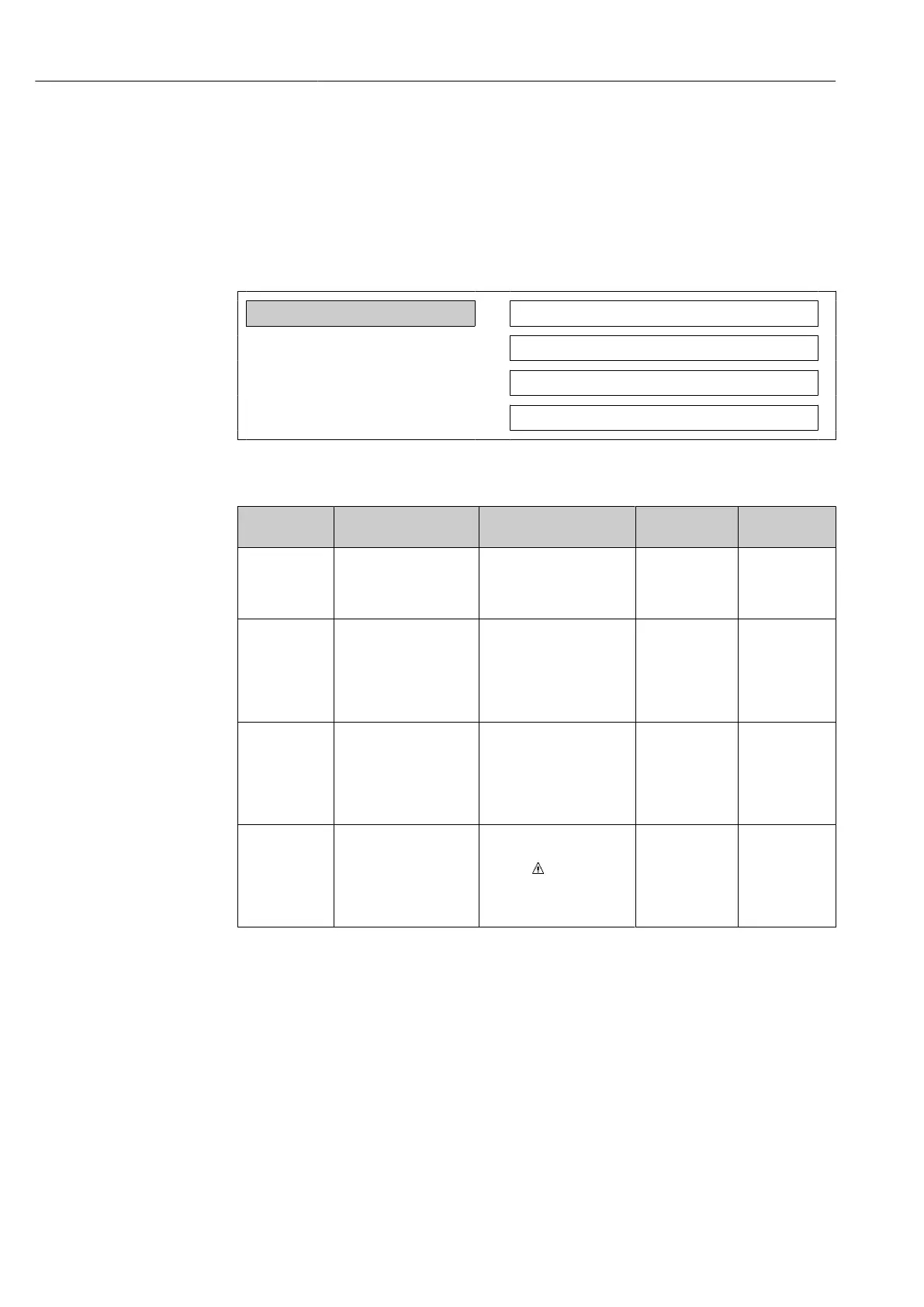

Parameter overview with brief description

Parameter Prerequisite Description Selection/

User entry

Factory setting

Assign process

variable

– Select a process variable to

detect empty or partially

filled pipes.

• Off

• Density

• Reference

density

Density

Low value

partial filled

pipe detection

One of the following

options is selected in the

Assign process variable

parameter:

• Density

• Reference density

Enter a lower limit value to

activate detection of an

empty or partially filled

pipe.

Max. 15-digit,

positive floating-

point number

Country-

dependent:

• 0.2 kg/l

• 12.5 lb/cf

High value

partial filled

pipe detection

One of the following

options is selected in the

Assign process variable

parameter:

• Density

• Reference density

Enter an upper limit value

to activate detection of an

empty or partially filled

pipe.

Max. 15-digit,

positive floating-

point number

Country-

dependent:

• 6 kg/l

• 374.6 lb/cf

Response time

part. filled pipe

detect.

One of the following

options is selected in the

Assign process variable

parameter:

• Density

• Reference density

Enter the time interval

until the diagnostic

message S862 Partly

filled pipe detection is

displayed for an empty or

partially filled pipe.

0 to 100 s 1 s

Loading...

Loading...