Diagnostics and troubleshooting Proline Promass E 100 Modbus RS485

72 Endress+Hauser

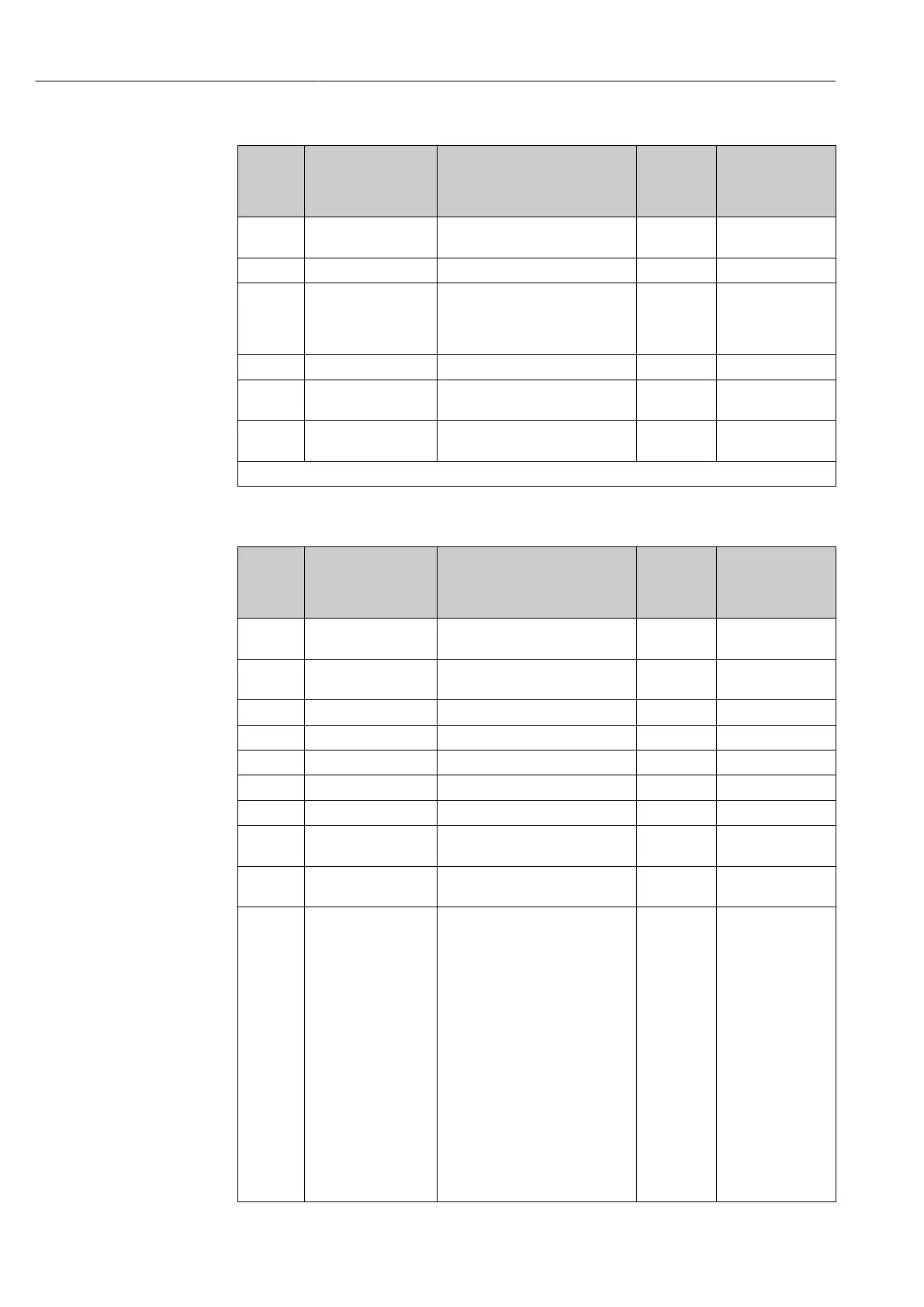

Diagnostics for the configuration

Diagnosti

c number

Short text Remedial measures

Status

signal

from the

factory

Diagnostic

behavior

from the factory

410 Data transfer 1. Check connection.

2. Retry data transfer.

F Alarm

411 Up-/download active Up-/download active, please wait C Warning

438 Dataset 1. Check data set file.

2. Check device configuration.

3. Up- and download new

configuration.

M Warning

453 Flow override Deactivate flow override. C Warning

484 Simulation failsafe

mode

Deactivate simulation. C Alarm

485 Simulation process

variable

Deactivate simulation. C Warning

*

Diagnostic behavior can be changed: "Adapting the diagnostic behavior" section → 70

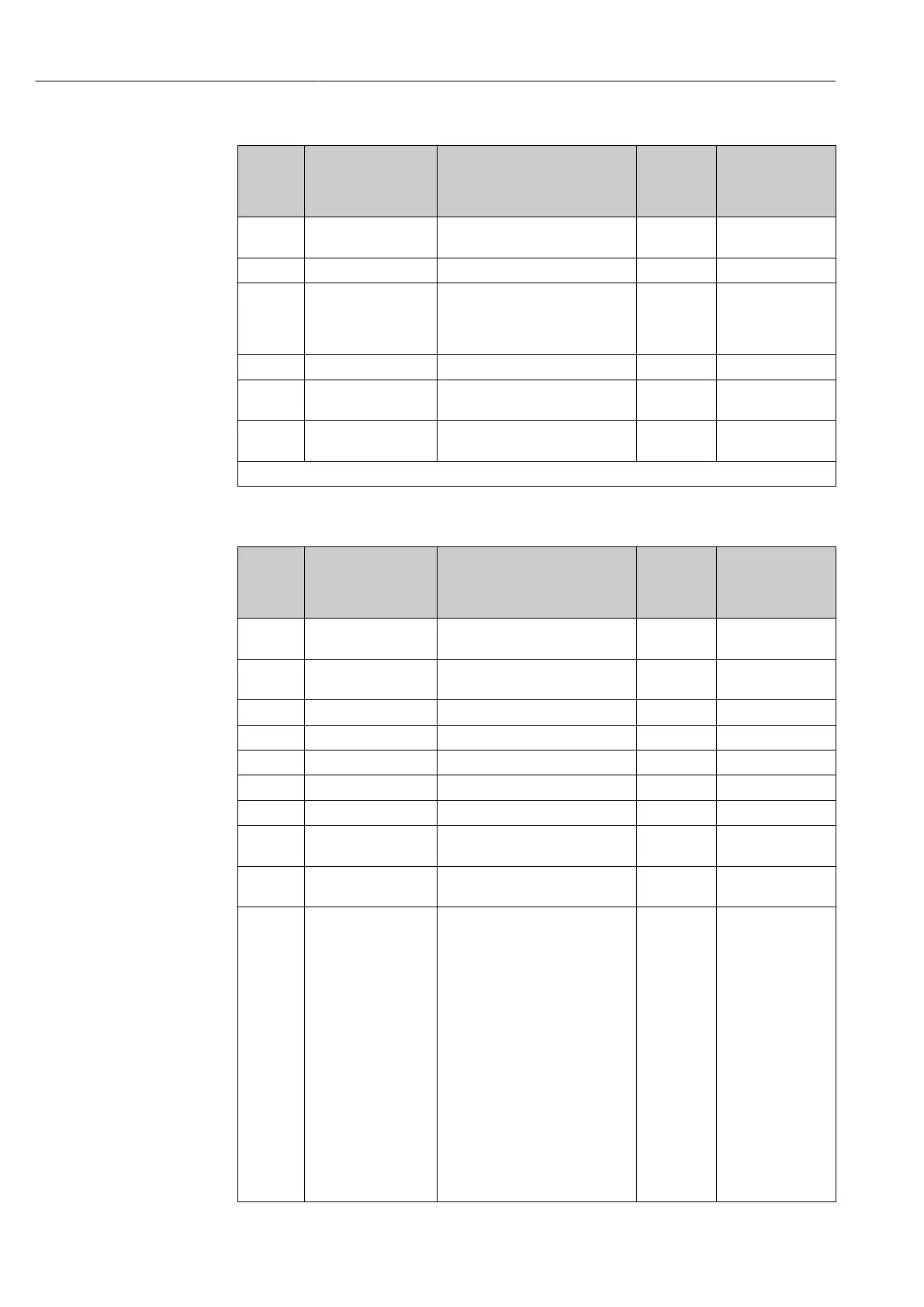

Diagnostics for the process

Diagnosti

c number

Short text Remedial measures

Status

signal

from the

factory

Diagnostic

behavior

from the factory

830 Ambient temperature Reduce the ambient temperature

around the sensor housing.

S Warning

831 Ambient temperature Increase the ambient temperature

around the sensor housing.

S Warning

832 Ambient temperature Reduce ambient temperature. S Warning

*

833 Ambient temperature Increase ambient temperature. S Warning

*

834 Process temperature Reduce process temperature. S Warning

*

835 Process temperature Increase process temperature. S Warning

*

843 Process limit Check process conditions. S Warning

862 Partly filled pipe 1. Check for gas in process.

2. Check detection limits.

S Warning

910 Measuring tube does

not vibrate

1. Check electronics.

2. Inspect sensor.

F Alarm

912 Inhomogeneous Fluid is inhomogeneous, e.g. gas or

solid content!

1. Check process conditions.

2. Increase system pressure.

In particular with outgassing

media and/or increased gas

content, the following

measures are recommended

to increase system pressure:

• Install the instrument at

the outlet side of a pump.

• Install the instrument at

the lowest point of an

ascending pipeline.

• Install a flow restriction,

e.g. reducer or orifice plate,

downstream from the

instrument.

S Warning

*

Loading...

Loading...