EPSON Stylus COLOR 860/1160 Revision C

Operating Principles Electrical Circuit Operating Principles 47

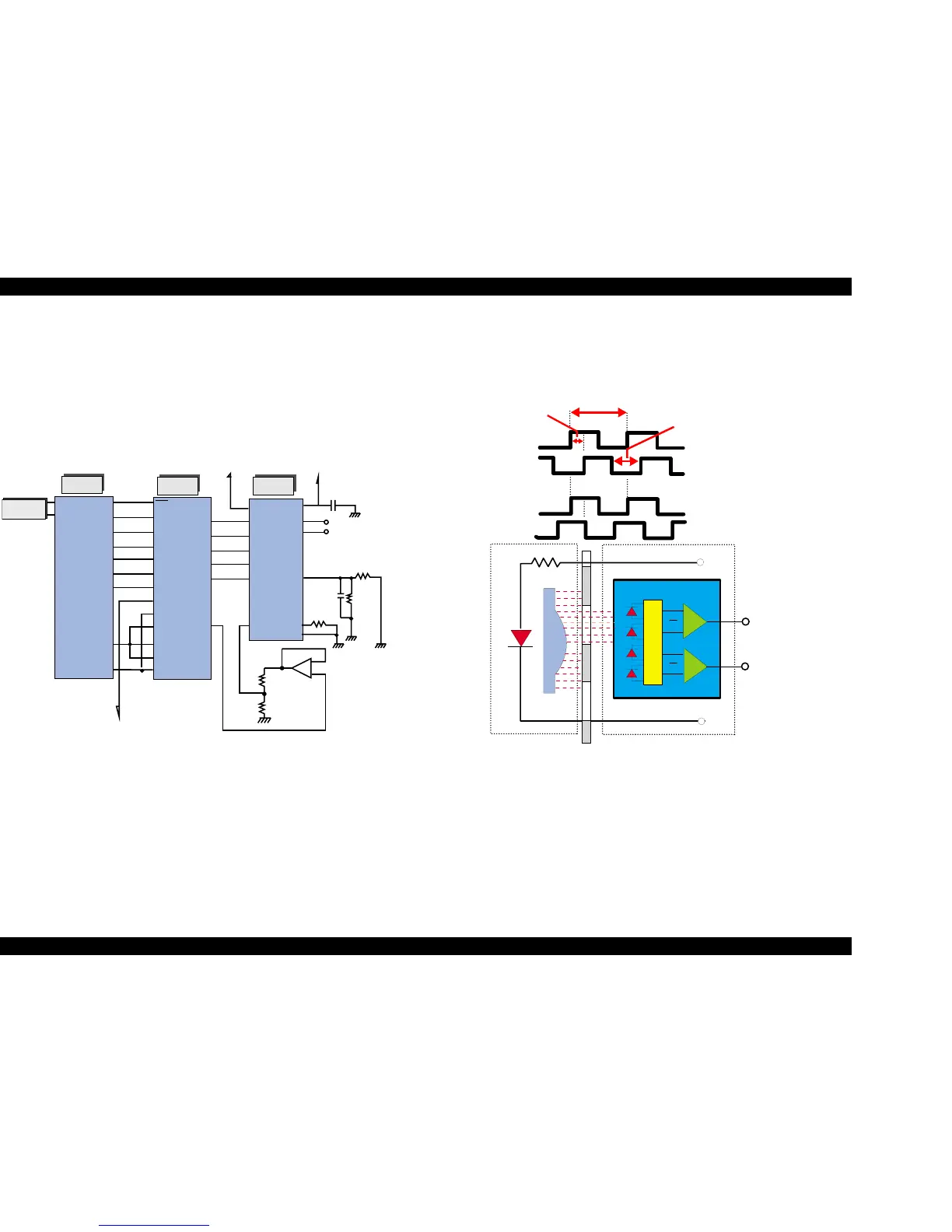

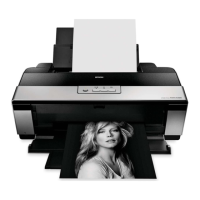

2.2.2.3 CR Motor Driver Circuit

The Stylus COLOR 860/1160 is equipped with a DC motor for the CR motor. In

addition to the CPU and ASIC, a slave CPU is mounted on the C298MAIN

board. Since the slave CPU is exclusively used to control DC motors, it

reduces duty of CPU and ASIC to offer faster data processing.

o CR motor driver circuit

The internal equivalent circuit of the CR motor driver IC (LB1947) is as

shown below.

Figure 2-19. Internal Equivalent Circuit of the CR Motor Driver IC

The

IC15 slave CPU

controls the CR position by referring to the pulses sent

from the linear encoder via IC8 ASIC. The CPU also sets an appropriate

drive current value for the CR position and the direction in which the CR

moves based on the data transmitted from the ASIC. So the slave CPU

outputs specified control signals to the motor driver. The motor driver IC18

then outputs the CR motor drive current to the CR motor based on the

signals sent from the

IC15 slave CPU

.

Unlike a stepping motor, the DC motor that drives the carriage

can not detect

the current carriage position by referring to the pulses given. For this

reason, a linear scale is attached along the carriage operation range to

detect the carriage position. The linear encoder sensor outputs two

kinds of TTL level pulses Phase A and Phase B to IC8 ASIC.

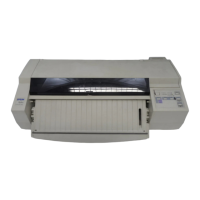

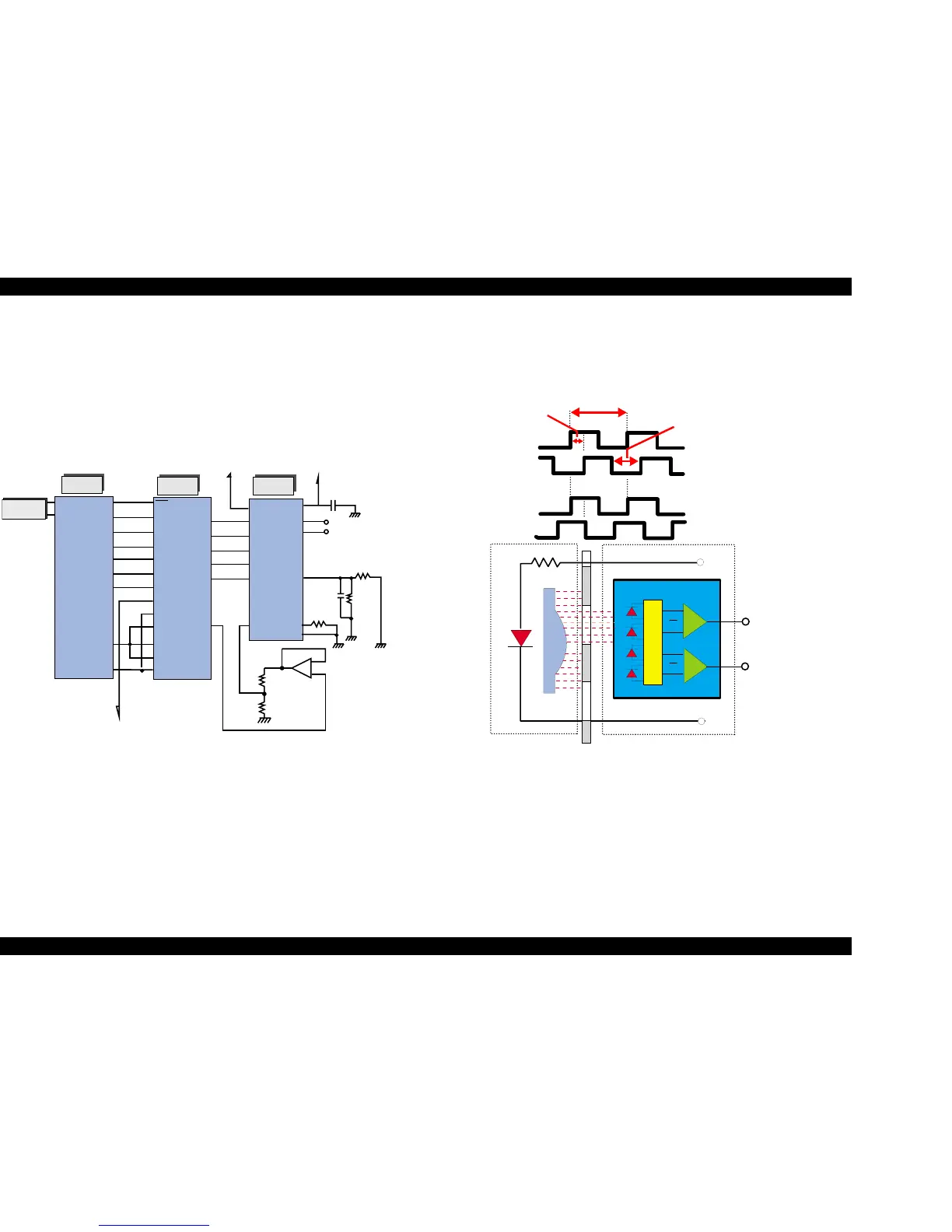

Figure 2-20. CR Linear Scale Encoder Pulse

Direction for the current CR’s movement is detected based on the waveforms

of the Phase A and Phase B that are out of phase, while carriage position is

controlled by using the waveforms output from Phase A on a cycle basis (1

cycle: 1/180 inches). Phase between the output waveforms A and B is as

shown in Figure 2-20. Note all edges in Phase A, Phase B output waveforms

(1/720-inch cycle) are used to control the CR position while it is in the home

position for ink system.

IC 1 8

LB1947

IC 1 5

C 90A 13C A

IC 8

E05B 70C D

CR-A

CR-B

OUTA

OUTB

-

NMI

NMI

P31

RXD1

P33

TXD 1

P32

CRBI3

P30

CRPHAB

P64

CRENBB

RES

CRAI2

MD2

P25

CPU

CRBI3

CRAI0

ENA

ENB

CRAI1

CR

E

GND

R 115

68BK

R114

12.7K

C 117

1500p

R112

0.499

C 115

0.1U

+5V

+42V

VBB

IN 1

IN 2

ST

VI

MD

PE1

PE2

PE0

PE4

PA0

VREF

+

-

IC 2 4

M 62552FP

R138

4.4BK

R139

4.99BK

DA1

P12

P26

P11

P13

P27

CRBI2

CN8

Head FFC

A

A

B

B

+

-

+

-

Photo

D iodes

C om parators

LEN S

LED

Phase A

Phase B

Phase A

Phase B

Phase A

Phase B

1/720 inches

1/180 inches

1/360 inches

CR Motor CW rotation

CR motor CCW

Loading...

Loading...