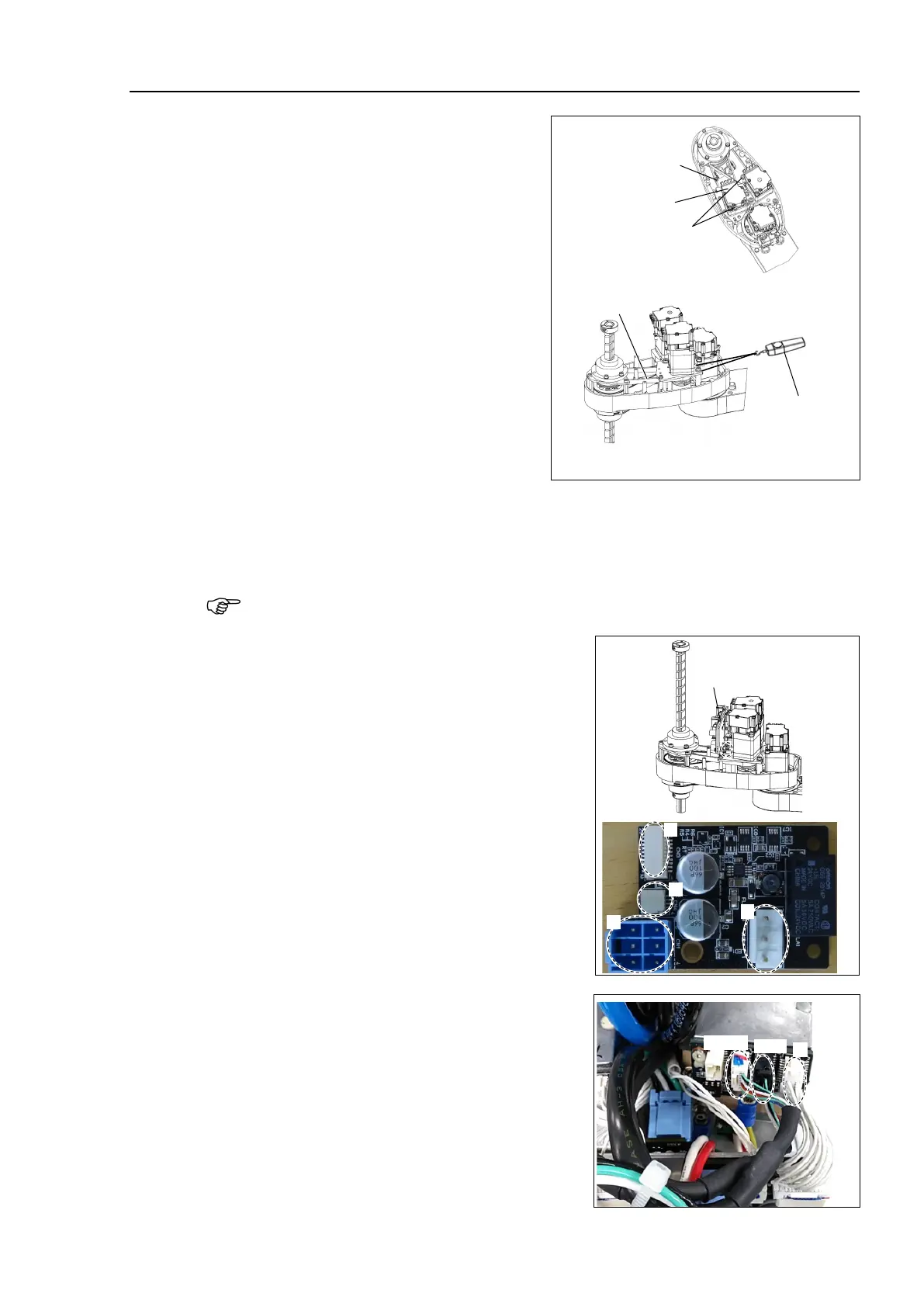

T3-B T6-B Maintenance 11. Joint #3

T-B series Maintenance Manual Rev.1 91

to the Z belt, and

secure the Joint #3 motor unit.

T3-B: a: 2-M4×15+M4 slotted hole washer

b: M3×12+M3 slotted hole washer

T6-B: ab: 3-M4×15+M4 washer

Pass a suitable cord or string around the

plate hole of the Joint #3 motor unit. Then,

pull the

cord using a force gage or similar

tool to apply the specified tension shown

below.

Z belt tension:

34.5 N (3.5 ± 0.5 kgf)

Axial force (when pulling):

69.0 N (7.0 ± 0.5 kgf)

following torque to secure the plate.

M3: 2 ± 0.1 N·m

M4: 4 ± 0.2 N·m

To check belt tension with the tension meter, refer to the following.

11.4 Checking the Timing Belt Tension (Z Belt)

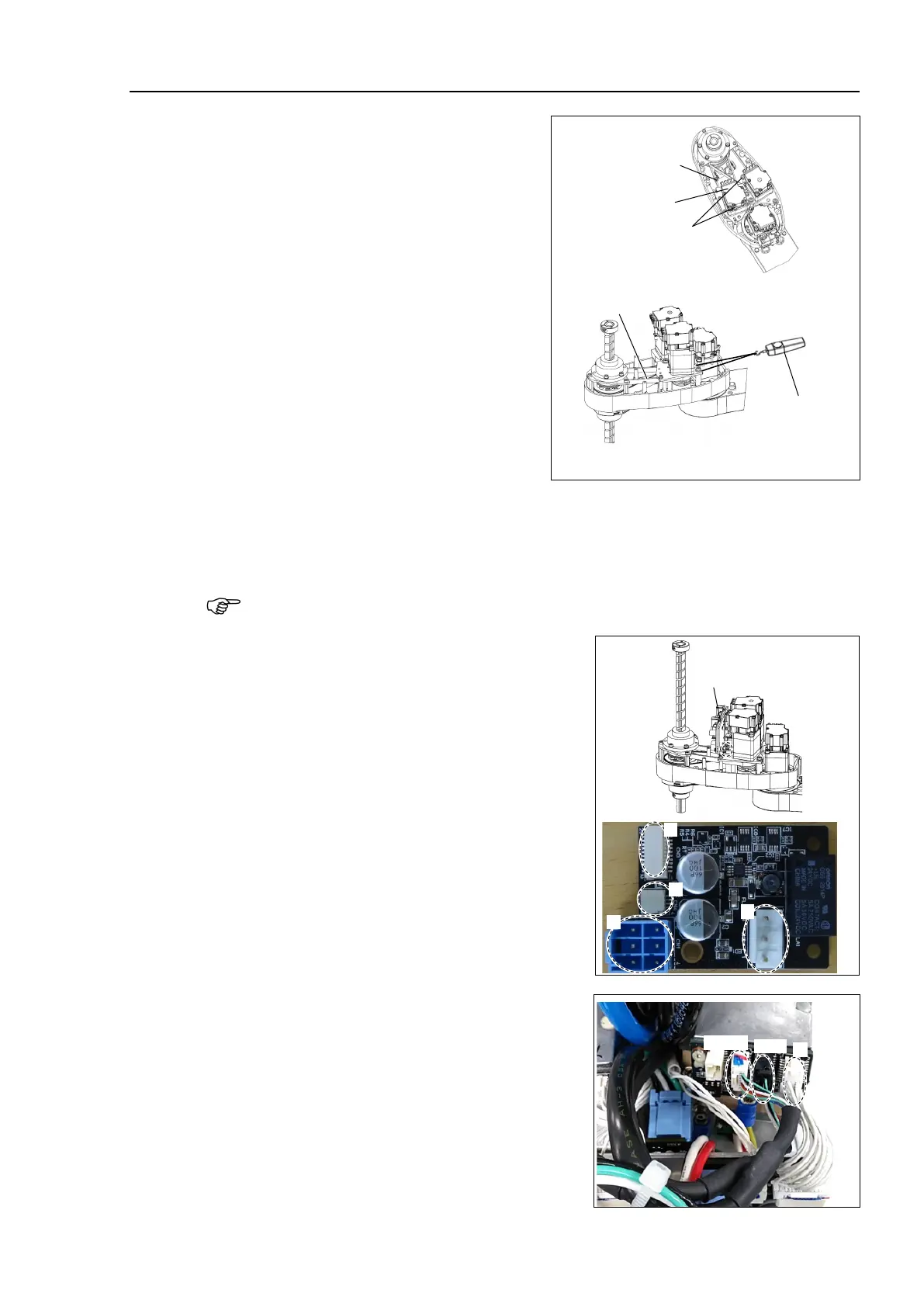

Mount the Joint # 2, 3, 4 AMP board unit.

Sems bolt: 2-M3×10

Tightening torque: 0.9 ± 0.05 N·m

Connect the following connectors to the AMP

board unit.

A: Power cable connector (×3)

B: AMP cable connector (×3)

C: Motor cable connector (×3)

D: Brake cable connector (×1)

Joint #2, 3, 4 AMP

board unit

Connect the connector of Joint #3 motor unit.

A: AMP cable connector (×1)

B: Signal cable connector

(IN/OUT ×1 for each)

Loading...

Loading...