T3-B T6-B Maintenance 12. Joint #4

T-B series Maintenance Manual Rev.1 101

Mount temporarily the motor plate on the Joint

#4 motor.

2-M4×55 +M4 small washer

When mounting temporarily the motor plate, be

careful of

the positions of the motor plate and

Check that the motor can be moved by hand,

and it will not tilt when pulled.

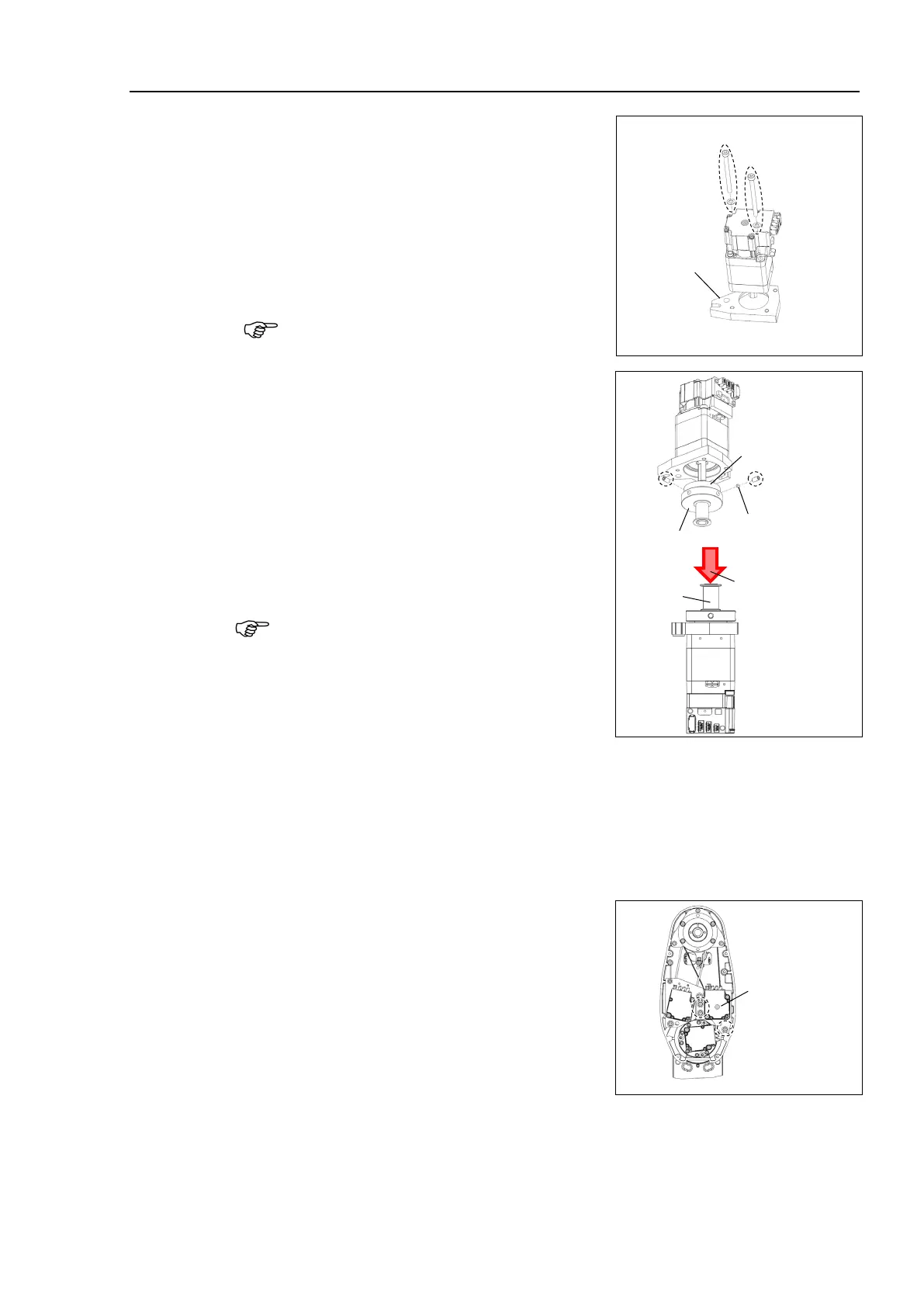

Mount the pulley and the bearing on the Joint

#4 motor.

M4×8 set screw

M4×8 set screw+M4 bushing

Tighten one of the set screws and bushing

vertically on the flat face of the motor shaft.

Secure using the set screw and the bushing

while preventing damage to the motor shaft.

Make sure that the bearing is inserted

completely when

mounting the pulley. If the

end faces of the motor plate and bearing fit,

bearing is inserted completely.

When tightening

set screw

Payload: 2.9±0.1kg

Give a pressure to bearing when tightening.

Pressure: 2.9±0.1kg

following torque to secure the pulley.

Tightening torque: 2.5 ± 0.15 N·m

Mount the motor plate on the Joint #4 motor.

T3-B: 3-M4x20+M4 slotted hole washer

T6-B: 3-M4x20+M4 washer

Tightening torque: 4 ± 0.2 N·m

Loading...

Loading...