T3-B T6-B Maintenance 9. Joint #1

T-B series Maintenance Manual Rev.1 65

units mounting

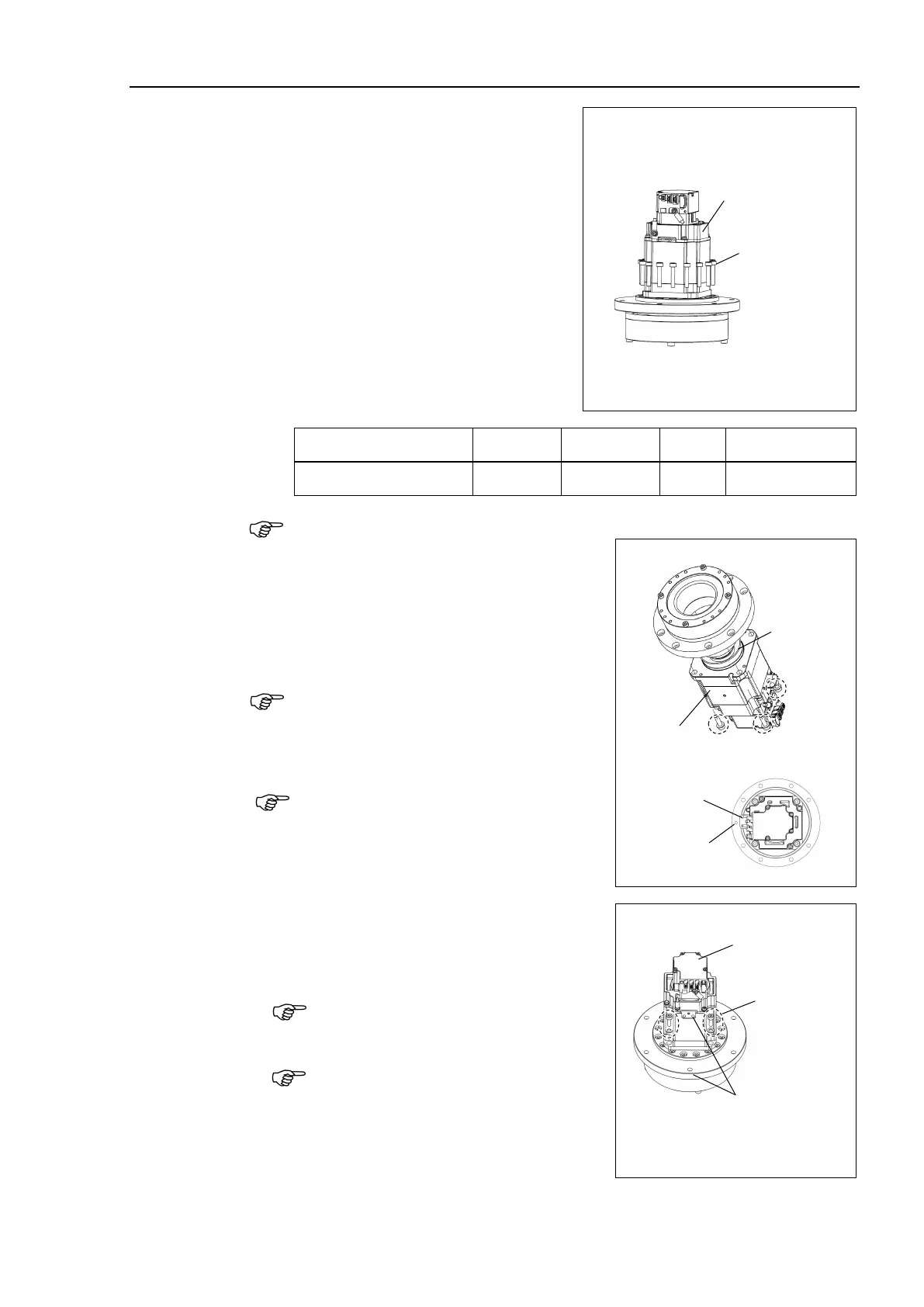

Rotate the motor around the shaft so that

the reduction gear units mounting screws

are visible, then operate.

T6-B: 16-M4×22

Loosely fasten all bolts in a crisscross

pattern so that the bolts will be fastened

evenly.

torque wrench, tighten each

bolt securely in a crisscross pattern at the

torque specified in the table below.

Name Model Bolt type Bolts Tightening torque

Joint #1 reduction gear units T6-B M4×25 16 5.5 ± 0.25 N⋅m

Be careful not to apply too much force since it may damage the parts.

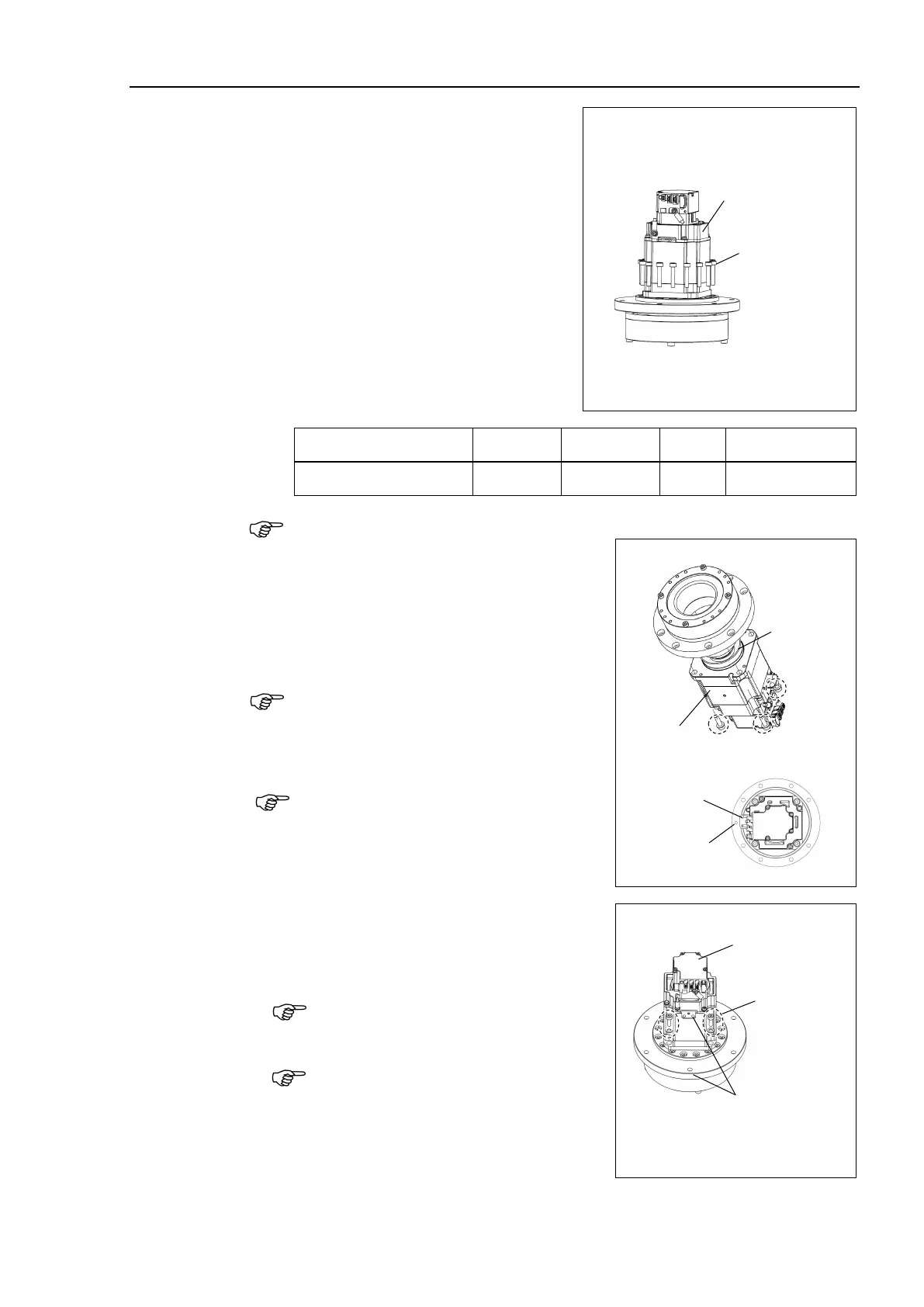

T3-B : Set the O-ring (between the motor and

the flange) on the motor mounting

surface, and temporarily secure the

motor unit on the Joint #1 flange.

4-M4×15+small washer

Be careful of the direction of the motor. Align

the orientation of the motor board with the

alignment dent in the flange.

Secure temporarily the screws.

After this, an alignment of the reduction gear

units are performed.

(Secure so that the screw head lightly touches

the flange base.)

-B: Mount the motor mounting screws.

4-M4×12+small washer

Be careful of the direction of the motor.

Align the orientation of the motor board

with the alignment dent in the flange.

Secure temporarily the screws.

After this, an alignment of the reduction

gear units are performed.

(Secure so that the s

touches the flange base.)

Align the orientation

of the motor board

with the dent

Loading...

Loading...