T3-B T6-B Maintenance 10. Joint #2

76 T-B series Maintenance Manual Rev.1

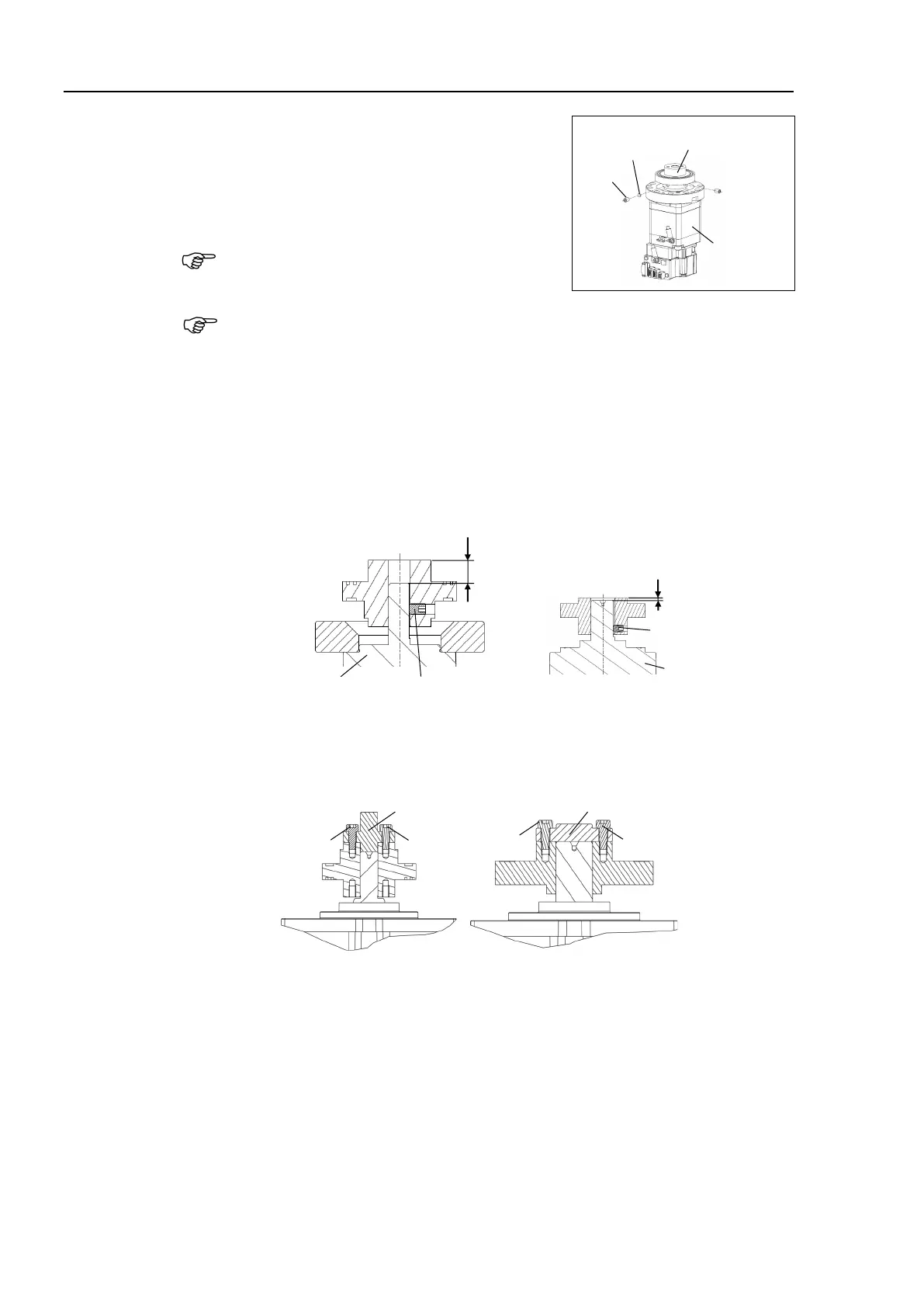

elliptic cam bearing from the Joint

2-M4×6 set screw

M4 brass bushing

There is a brass bushing in one of the set screw

holes. Be sure not to lose the bushing.

Motor

tightening hexagon socket head cap bolts, refer to “2.4 Tightening Hexagon

”.

elliptic cam bearing on the Joint #2 motor.

Mount the bearing so that the end faces of the

elliptic cam bearing and the motor

shaft have the following dimensions.

T3-B: 8.5 mm

T6-B: 1.5 mm

Be careful of the direction of the

elliptic cam bearing.

Set screw is on the

end of motor shaft

Set screw is on the

end of motor shaft

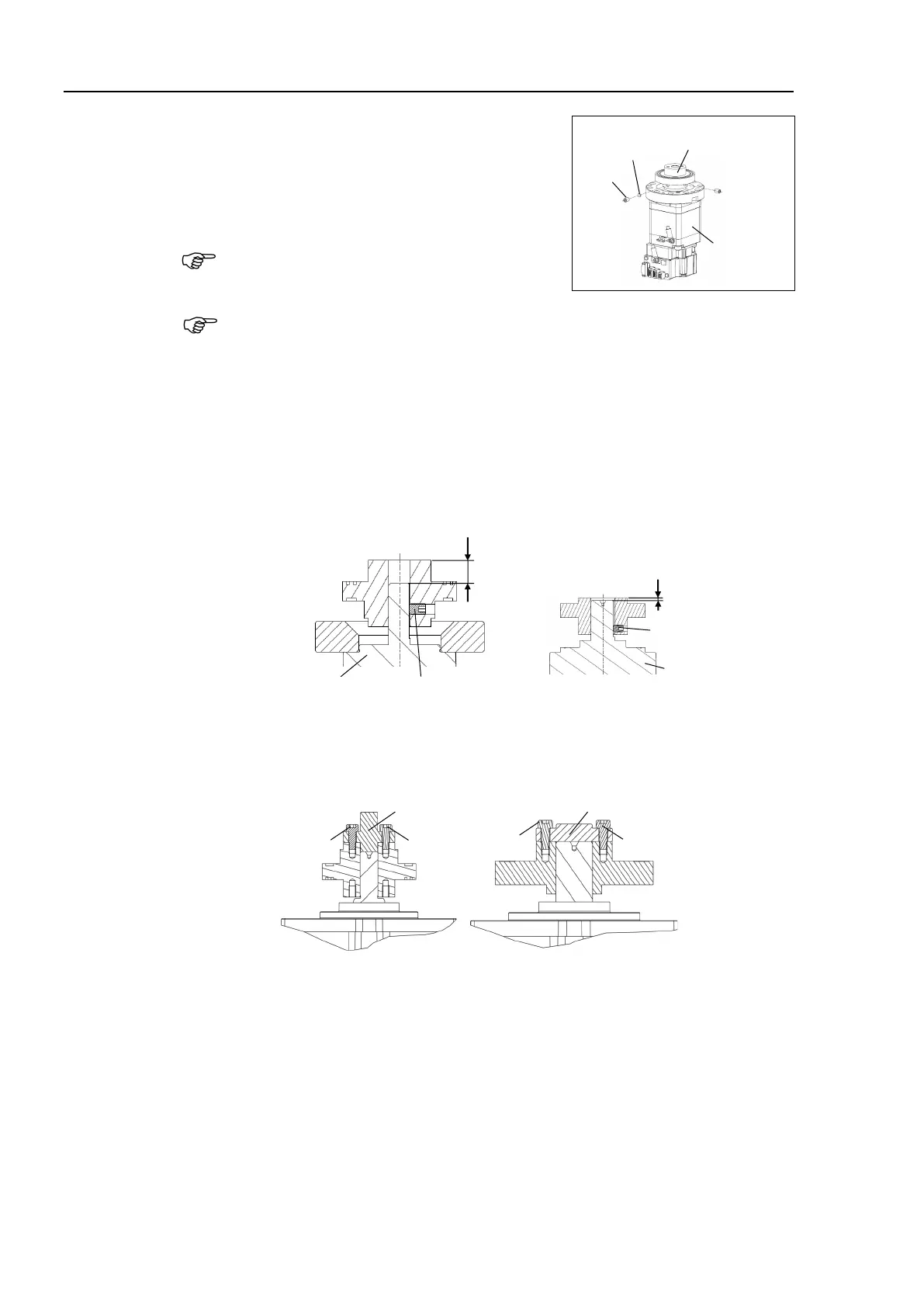

elliptic cam positioning jig, mount the jig and temporarily secure it.

Secure so that the screw head lightly touches the jig.

Jig to set the position of

elliptic cam bearing

Jig to set the position of

elliptic cam bearing

The jigs for T3-B and T6-B have different dimensions. Be careful of the dimensions.

Loading...

Loading...