T3-B T6-B Maintenance 10. Joint #2

T-B series Maintenance Manual Rev.1 77

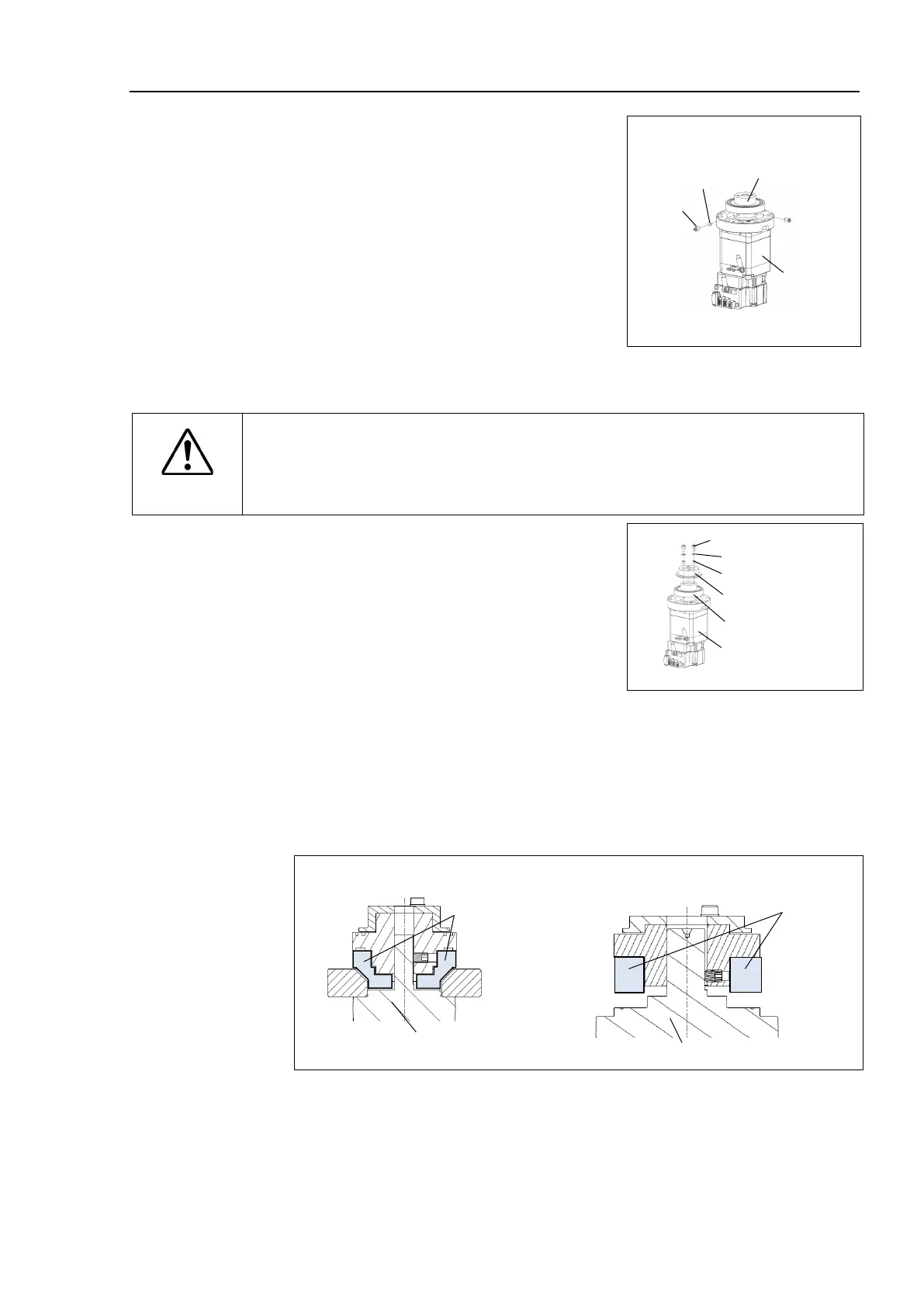

elliptic cam bearing by the set screw.

2-M4×6 set screw

M4 brass bushing

Tightening torque: 2.5 ± 0.15 N·m

Tighten one of the set screws on the flat face of

the motor shaft until the

screw just touches the

surface. Insert a bushing into the other set screw

hole to prevent damage to the motor shaft. Then,

tighten both set screws.

elliptic

cam positioning jig, unscrew the temporarily securing screws

and remove the

elliptic cam positioning jig.

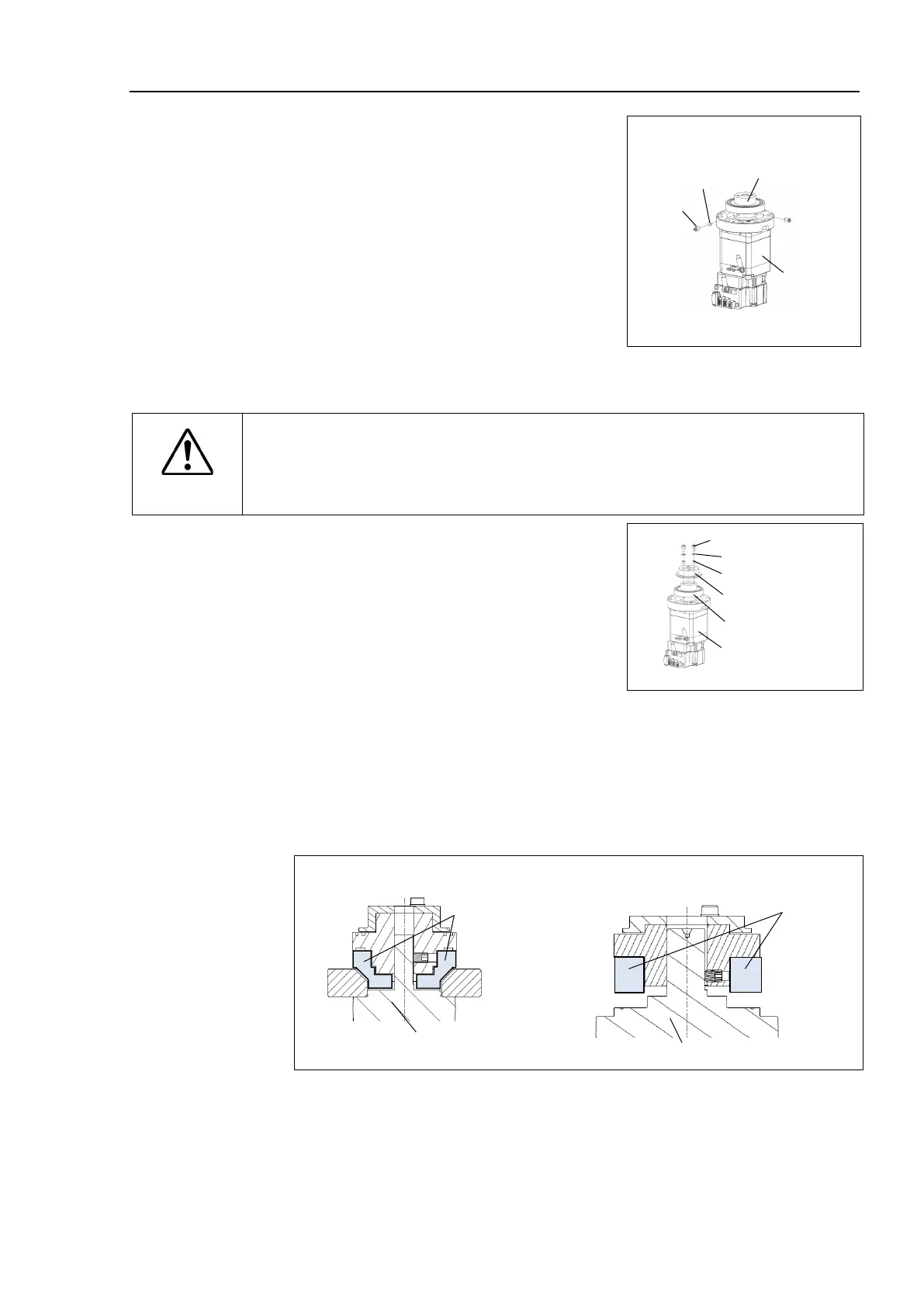

CAUTION

■

Refer to the figure above for the orientation of the

elliptic cam bearing. Be sure to

elliptic cam bearing properly.

elliptic cam bearing will result in improper function of the

Mount the grease receiver to the

elliptic cam

bearing on the Joint #2 motor.

2-M3×6+washer+collar

Tightening torque: 1 ± 0.2 N·m

Grease volume

T3-B: Between the motor flange and the elliptic cam bearing

SFB No.1: 4g

T6-B: Between the motor and the elliptic cam bearing

SFB No.1: 6g

Loading...

Loading...