MCS- 48/92 Digital Brushless AC servo drive system - Ref.0707

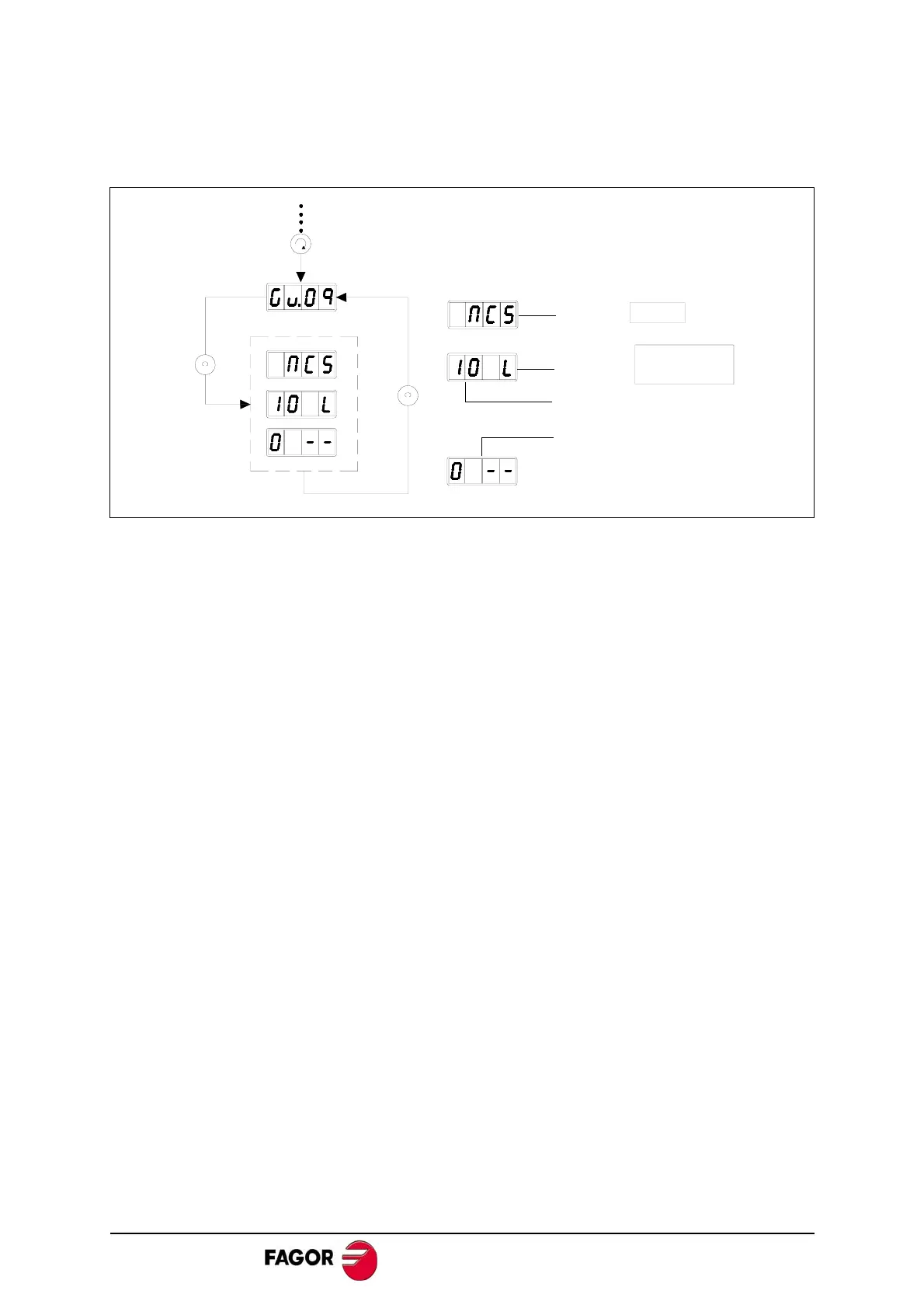

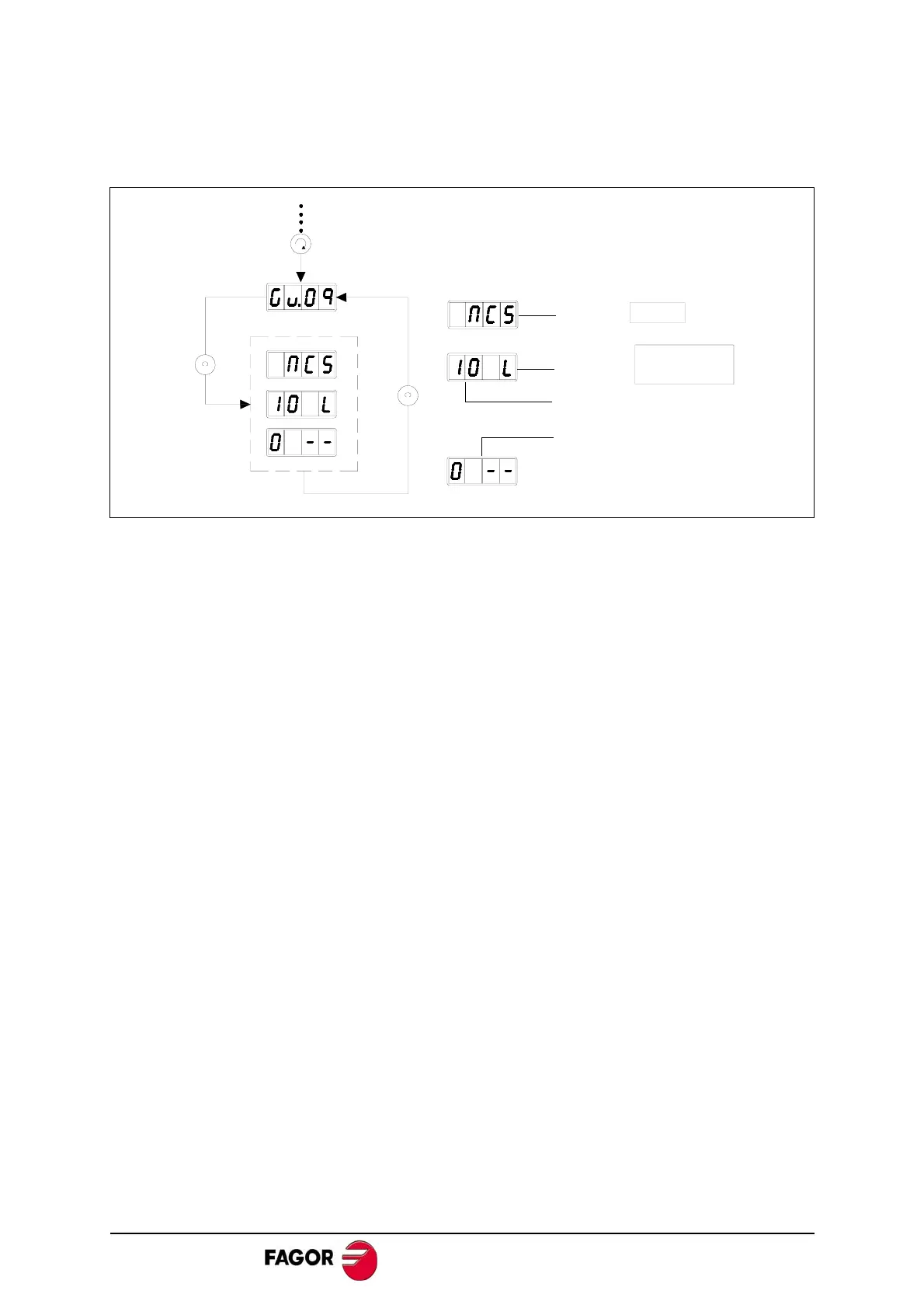

To obtain information on the type of drive (it can be read but not edited) coherent with

the selected motor, find GV9 and follow the indication of the figure below to display the

different fields that show their characteristics:

If for any reason, the access level must be changed, display the GV7 variable and write

the new code. Then, display GC1 and apply the command as described earlier. Finish

the procedure with a reset.

On the other hand, when adjusting it, proceed as follows:

Verify that desired velocity or current command is selected. To do this, make sure that

all the parameters involved (such as SP45, WV4,...) are properly set.

When using external analog command, verify that it is output to the proper pins.

When using analog command, set parameters SP20 and SP21 with the proper values

in order to obtain the desired response to the velocity command entered.

Use parameter CP20 to set the maximum peak current value of the drive to obtain the

best dynamic response.

Set the velocity PI gain using parameter SP1 (proportional gain K) and SP2 (integral

K) until the desired system performance is obtained.

Adjust the velocity offset using parameter SP30.

Send a 0 V velocity command to the drive (jumpering pins 4, 5 and 6 of connector X1).

Measure the motor speed and adjust the offset using parameter SP30 until the motor

stops. Be careful because this method only eliminates the offset of the drive. The CNC

may have an offset of its own which must be adjusted at the CNC.

In order to adjust the offset for the whole control loop:

Set the CNC in DRO mode keeping the Drive_Enable and Speed_Enable signals

active.

Change parameter SP30 until the motor stops.

Another method would consist in setting an axis position with the CNC and adjusting

parameter SP30 until the following error (axis lag) is symmetrical.

MCS

Model:

Peak current

Power

Supply:

L 220 V AC

H 400 V AC

Future

implementations

Loading...

Loading...