108

OPERATION

24. Track adjustment

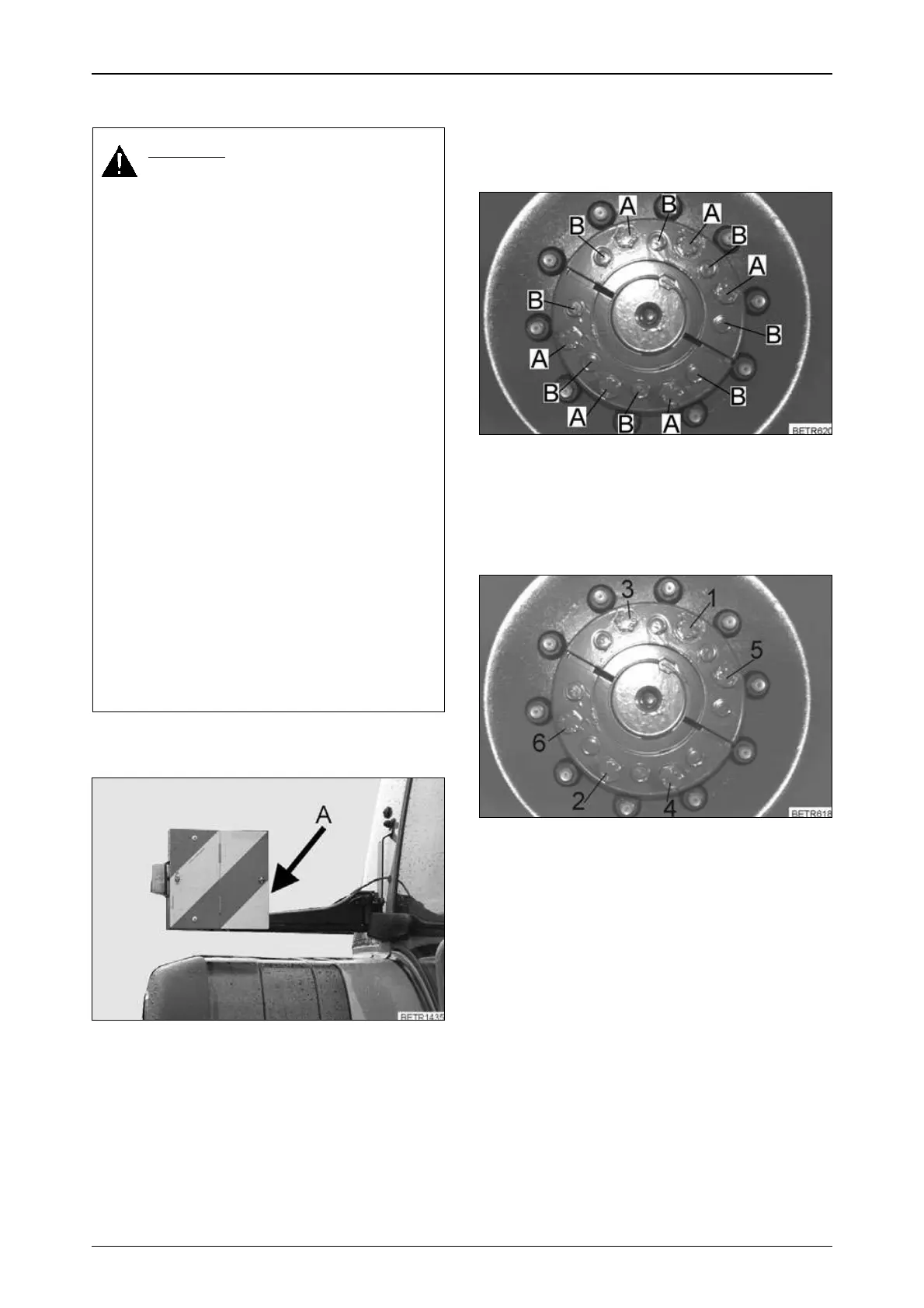

24.1 Lighting wide vehicle

Operation_Pic_number:1

Apply left and right warning signs flush with the

outer edge of the tyre.

Tighten locking screw (A) at 5 Nm.

DANGER:

When working on tyres, make sure

the tractor is properly parked and

secured against rolling away (wheel

chocks)!

If the engine needs to be started for

turning the wheels, both wheels

must be jacked up and turn free.

When the tractor is jacked up and

some one is working underneath, no

one else should be on the tractor.

If the tractor is lifted with the lower

links, additional supports are

required!

Tyre repairs should be performed

only by qualified personnel using

suitable tools.

Tyres may explode if the air pressure

is too high! Check tyre pressures

regularly!

Do not use special protective tyres

for heavy-duty traction work or front

loader operations; maximum road

speed 25 km/h.

After wheel mounting or track

adjustment, tighten the bolts and

nuts on front and rear wheels and on

track adjusting elements. Check

these regularly!

Fig.258

24.2 Rear axle stub

Text-module

(optional).

Change track width

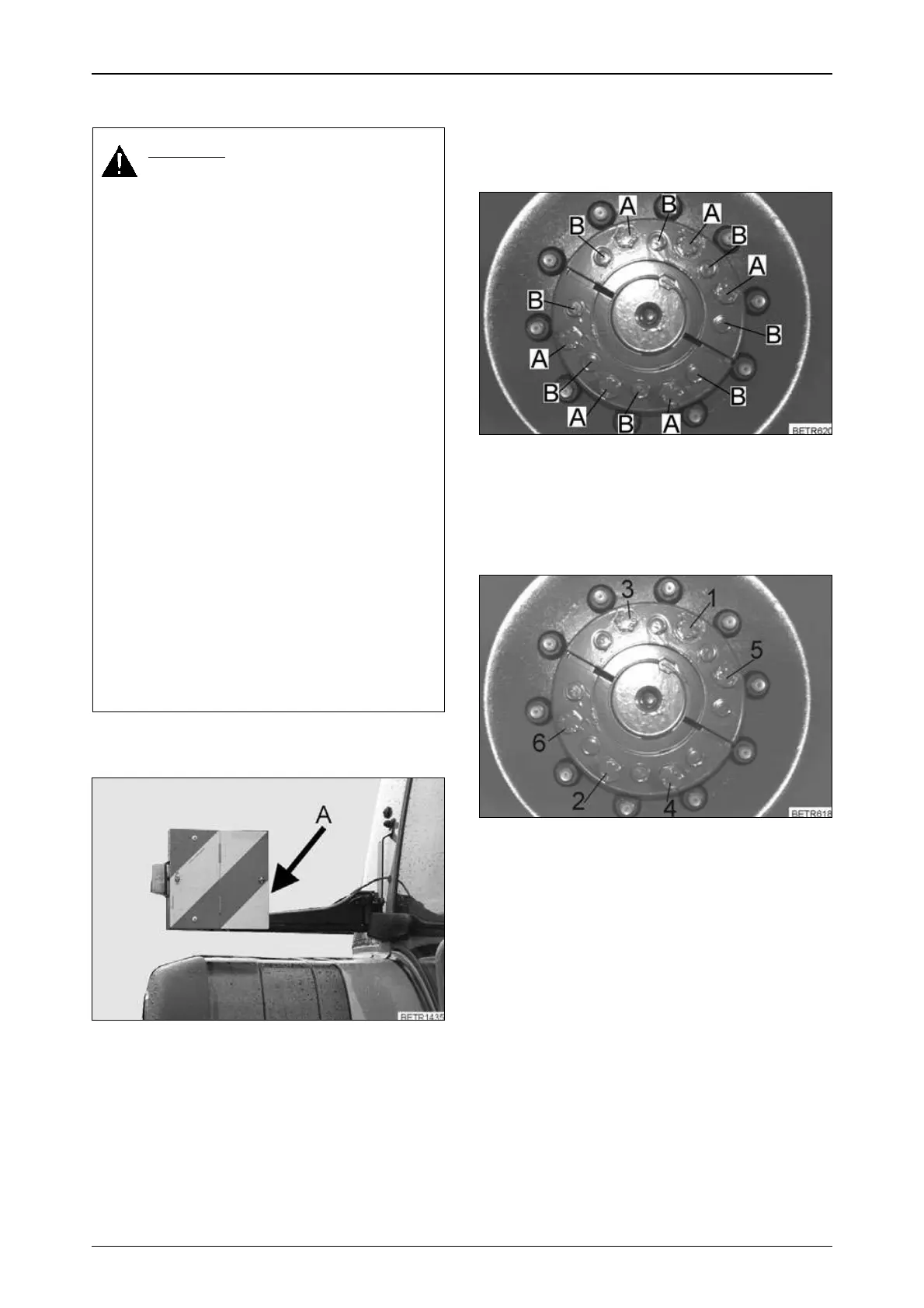

Operation_Pic_number:1

Jack up rear wheels, loosen screws (A).

Screw in the screws (in tool box) in hole (B) to

loosen the chuck cone.

Set to the desired track width.

Operation_Pic_number:1

If the track width is changed, the mounting bolts

should be tightened in accordance with the

following diagram.

1 = Tighten hexagon screws in the order

shown (1-6) at a torque of 200 Nm.

2 = Tighten hexagon bolts to Nm in the order

shown (1-6).

3 = Drive tractor for a couple of hundred

yards then retighten to 600 Nm in the or-

der shown (1-6).

4 = After another 3 operating hours, re-

tighten in the order shown (1-6), to

600 Nm.

5 = After 10 additional operating hours re-

tighten according to the shown pattern

(1-6) at 600 Nm.

Fig.259

Fig.260

Loading...

Loading...