2 Operating modes and functions

Festo – GDCP-CMMP-M0-FW-E N – 1304N H 11

2 Operating modes and functions

2.1 Overview

The following operating modes are available to support your application.

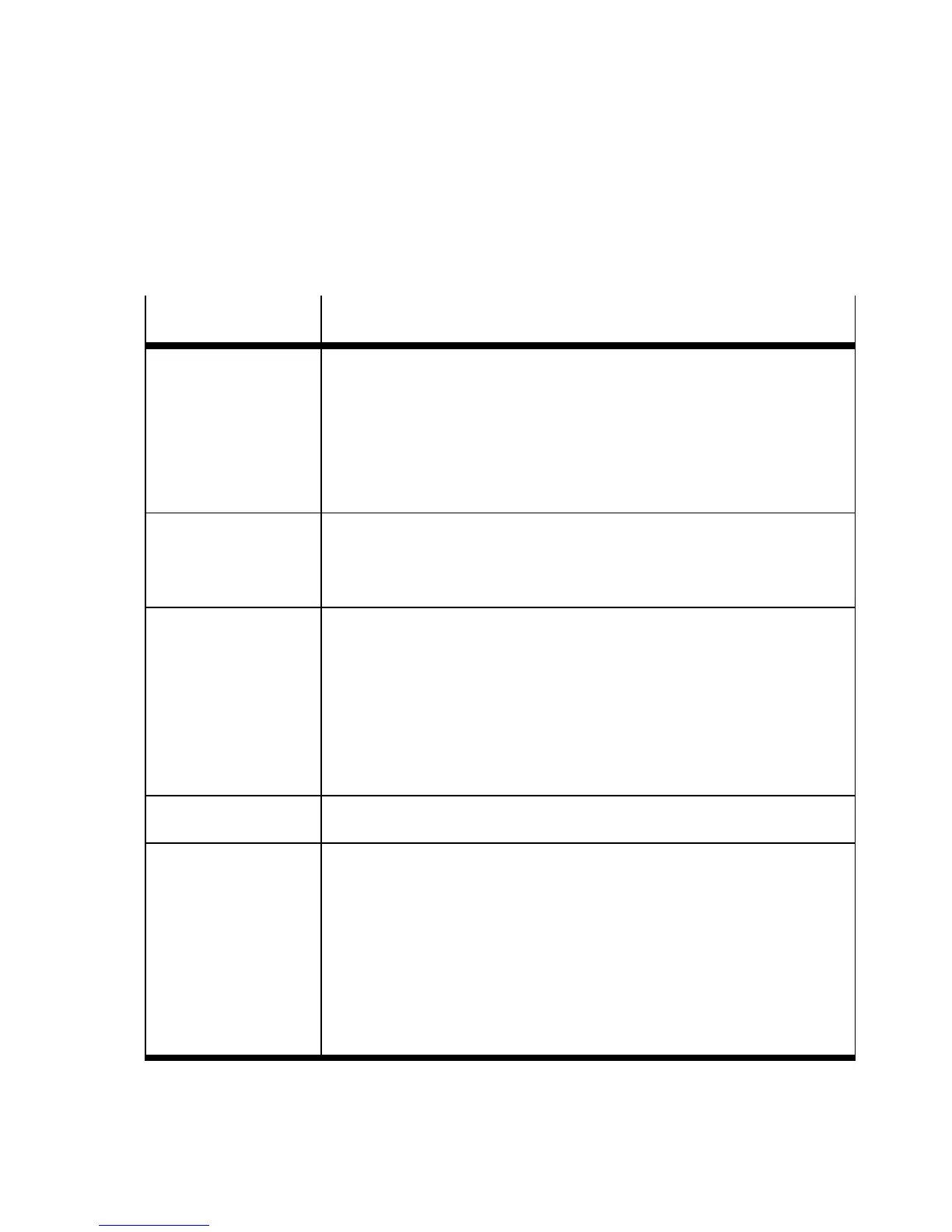

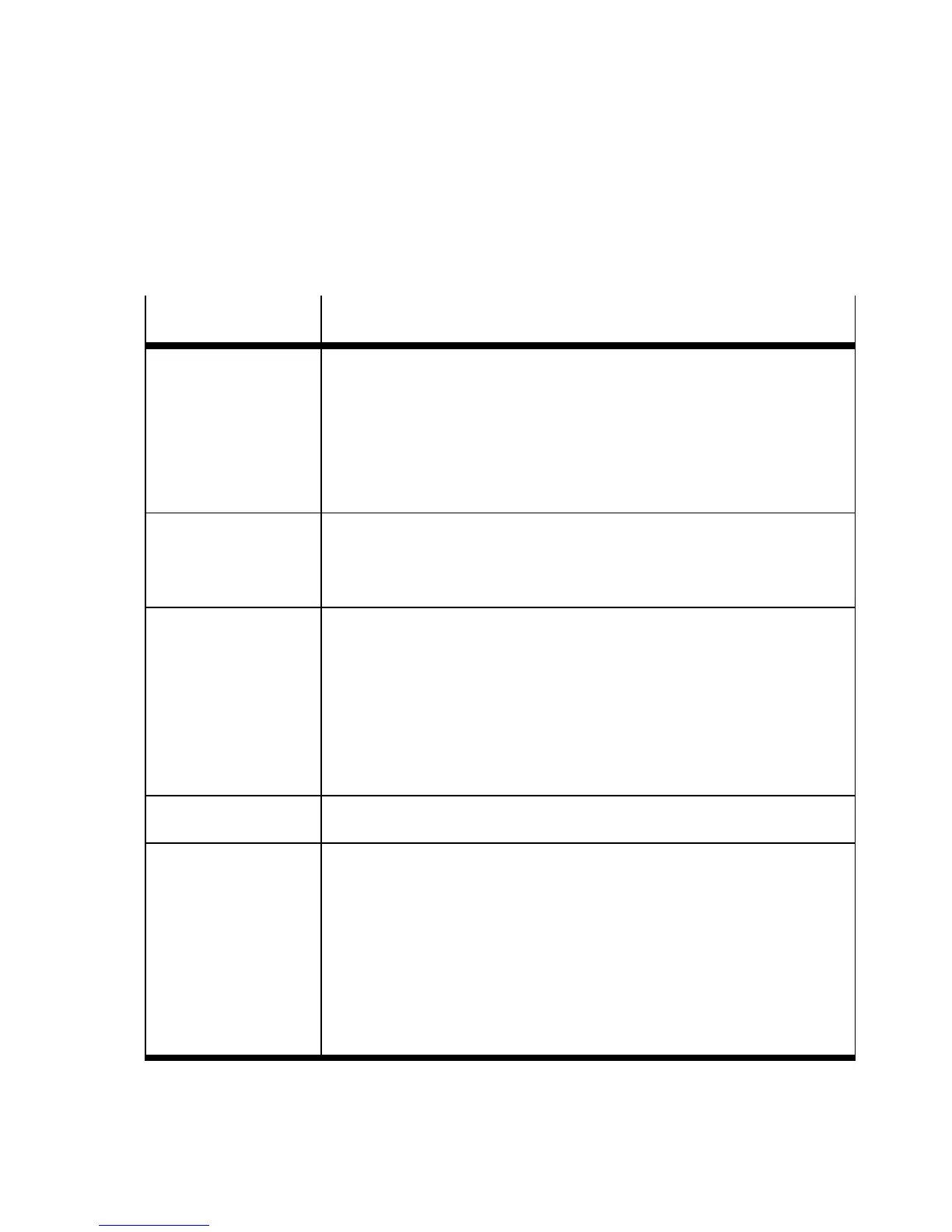

Operating mode/

functions

Description

Positioning mode

(Profile Position Mode)

Operating mode for executing a positioning record ( record selection) or a

positioning task (direc t mode). In addition to operation with speed control,

a higher-level position controller (setpoint value generator) is active; it

processes deviations between setpoint position and actual position and

converts it into corresponding setpoint specifications fo r th e speed

controller. For position control, the current settings for speed, acceleration,

deceleration, etc. are taken into account.

Speed-controlled

operation

(Profile Velocity Mode)

Operating mode for executing a positioning record (direct mode).

Regulation in accordance with speed setpoint values and profiles. In

speed-controller operation, current limitation can be activated through

specification of a force/torque limit value.

Force/torque

operation

(Profile Force/

Torque Mode)

Operating mode for executing a positioning record (direct mode) with

force/torque c ontrol ( c urrent control). This operating mode permits

specification to the c ontroller of an external force/torque setpoint value

(relative to the motor current). All specifications on forces/torques refer to

the motor nominal torque or the motor nominal current. Since force/torque

are proportional to the motor current, only t he current regulator is

activated in this operating case. In addition, speed limiting can be activated

through specification of a limit value.

Homing

(Homing)

Positioning mode with a sequence established through the homing method

for definition of the mechanical reference system (homing point).

Interpolated

positioning mode

(Interpolated position

mode in accordance

with CiA402)

Positioning mode with a sequence established through the homing method

for definition of the mechanical reference system (homing point)

– Travelling along trajectory curves

– Coupling of axes for multiple axis systems

– Axis error compensation.

The movement is parameterised for several axes in advance in the shape of

data points (position, speed, time) and loaded into the motor controllers.

Between the data points, the various axes interpolate automatic ally and

work off the movement profile synchronously in time.

Tab. 2.1 Overview of operating mo des

Loading...

Loading...