6Functions

Festo – GDCP-CMMP-M0-FW-E N – 1304N H 55

6.6.2 E x ample, toothed belt axis

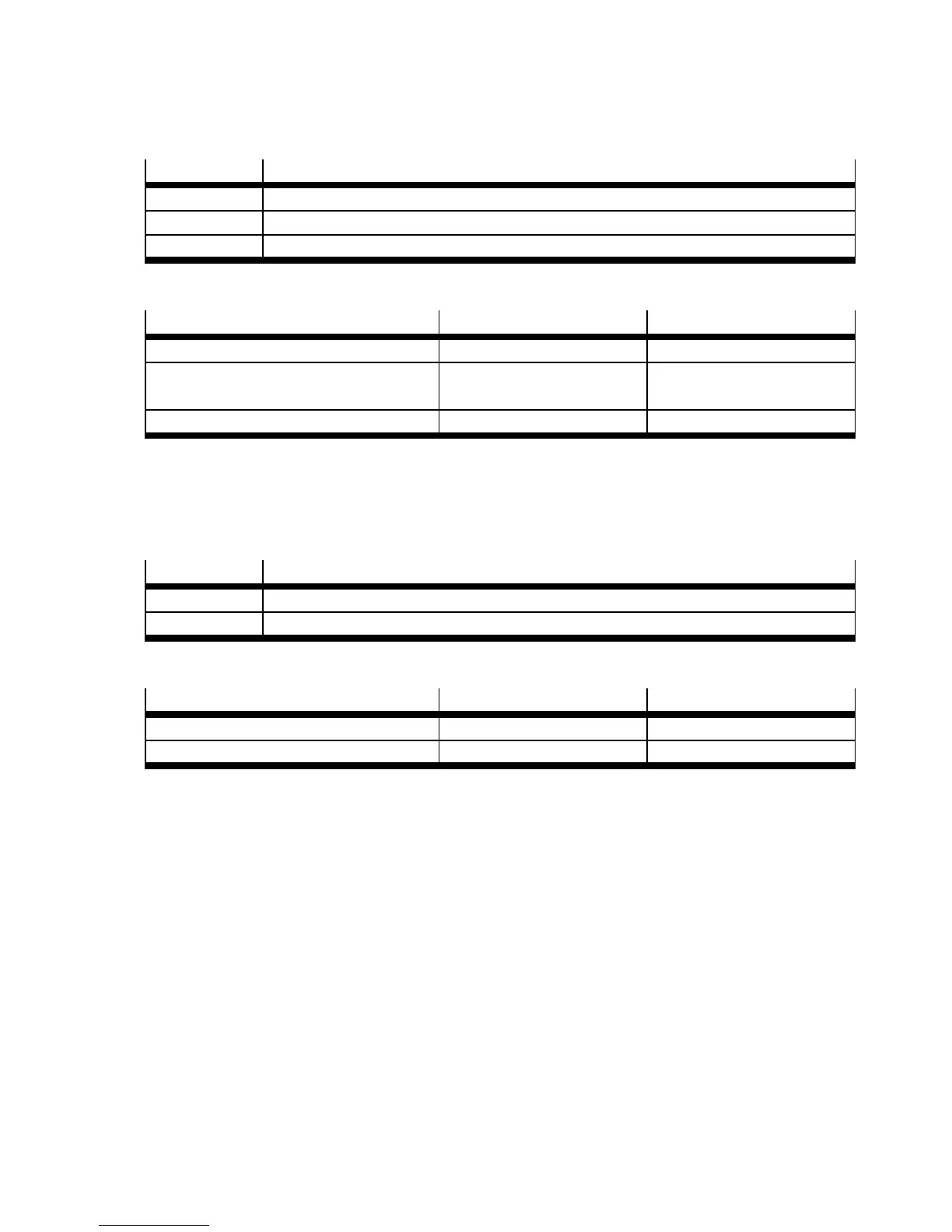

Component

Type

Motor EMMS-AS-70-M-Rx

Gear unit EMGA-60-P-G3-SAS-70

Axis EGC-80-2000-TB-KF-0H-GK (real feed constant 90.2 mm/R)

Tab. 6.16 Toothed belt axis c omponents

Parameterisation

Repetition accuracy Approx. absolute a ccuracy

Standard parameterisation [mm] 0.08 4.44

Parameters with real feed

constant

[mm] 0.08 0.44

External displacement encoder [mm] < 0.08

1)

< 0.10

1)

1) Depending on the system used (possible loose gears or gear backlash are compensated with the 2nd measuring system and thus

improve the absolute accuracy.)

Tab. 6.17 Repetition accuracy of toothed belt axis

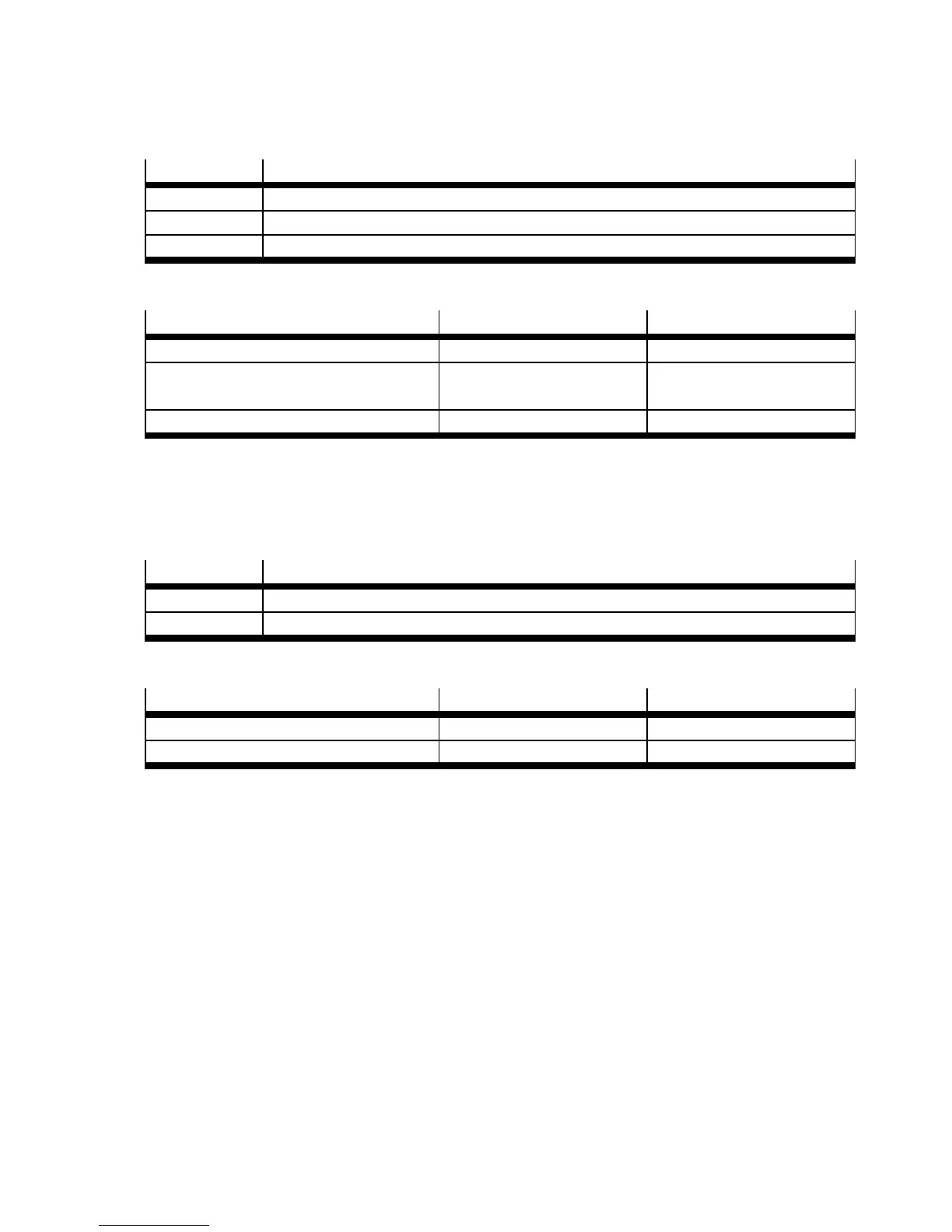

6.6.3 E x ample, spindle axis

Component

Type

Motor EMMS-AS-70-M-Rx

Axis EGC-80-2000-BS10-KF-0H-Mx-GK-S (Feed constant = 10 mm/R)

Tab. 6.18 Spindle axis c omponents

Parameterisation

Repetition accuracy Approx. absolute a ccuracy

Standard parameterisation [mm] 0.02 0.05

External displacement encoder [mm] < 0.02 < 0.05

Tab. 6.19 Repetition accuracy of spindle axis

6.6.4 Function in the motor controller

In the motor controller, the position actual value of the external displacement encoder is evaluated

instead of that of the motor encoder. Both commutation and speed adjustment continue t o be made

through the encoder in the motor.

Through encoder difference monitoring, an adjustable offset between the motor encoder and external

measuring system is detected and reported. Errors, for instance mechanical offset, failure of external

encoders or torn tooth ed belt, result in stopping with a corresponding error message .

Loading...

Loading...