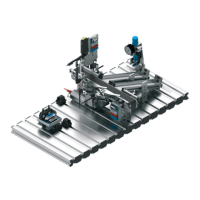

Sorting Station Inline

26 © Festo Didactic 8129444

10 Function

The Sorting Station Inline sorts workpieces on two slides or forwards the workpiece to the next application.

Workpieces placed onto the beginning of the conveyor belt are detected by a fork light barrier. The

workpieces are stopped briefly in order to determine their characteristics. The sensors in the detection

module ascertain the workpieces’ material and color (black, red, metallic).

The workpieces are sorted onto the appropriate slides by means of electrically operated deflectors. A retro-

reflective sensor monitors the level of the slides.

11 Sequence description

11.1 Start-up prerequisite

• Workpiece at the beginning of the conveyor

11.2 Initial settings

• Conveyor motor off

• Deflector 1 retracted

• Deflector 2 retracted

• Slides not full / no workpiece at end of conveyor

11.3 Sequence

1. Workpiece detected at beginning of conveyor

2. Conveyor motor on

3. Color/material detection

Black workpiece detected, deposited at end of conveyor

4. Workpiece is transported to end of conveyor

5. Workpiece at end of conveyor

6. Workpiece is forwarded if next station is free (I6 on control panel) or workpiece is manually removed

Loading...

Loading...