ST51A/ST75A/ST75AV Mass Flow Meters INSTALLATION

Fluid Components International LLC 5

2 INSTALLATION

The ambient temperature range and applicable temperature class of the ST51A and ST75A/ST75AV Series flow

meters are based on the maximum process temperature for the particular application as follows; T6 for -40 °C ≤ Ta ≤

+55 °C; T3 for -40 °C ≤ Ta ≤ +65 °C.

Instrument Identification and Outline Dimensions

Appendix A provides outline dimensions and mounting bracket dimensions for all integral and remote mounted electronic configurations.

Verify all dimensions meet the application requirements before beginning installation.

Pre-Installation

Serial Number

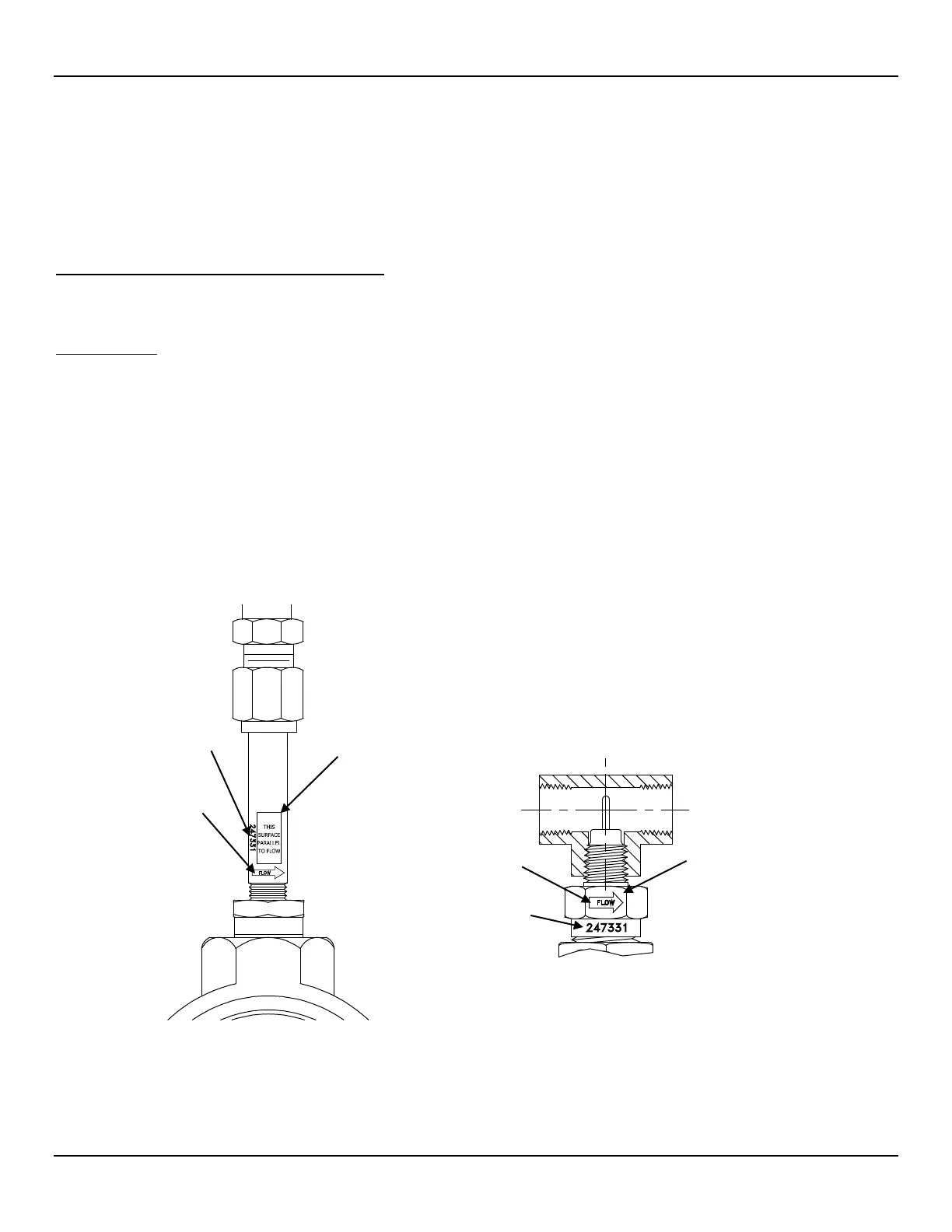

The ST51A, ST75A and ST75AV (Vortab) flow meters can be specified with integral or remote electronics. The flow element has a serial

number etched into the side of the extension pipe (ST51A) or HEX (ST75A/ST75AV) as shown in Figure 1 below. The tag on the enclosure

includes serial number and model number. A serial number is written on the transmitter’s PWB silkscreen (both AC and DC input) as

shown in Figure 2. The flow sensor and transmitter circuit are calibrated as a matched set. Always pair these components together unless

an exception is made by an FCI technician.

Flow Direction Alignment

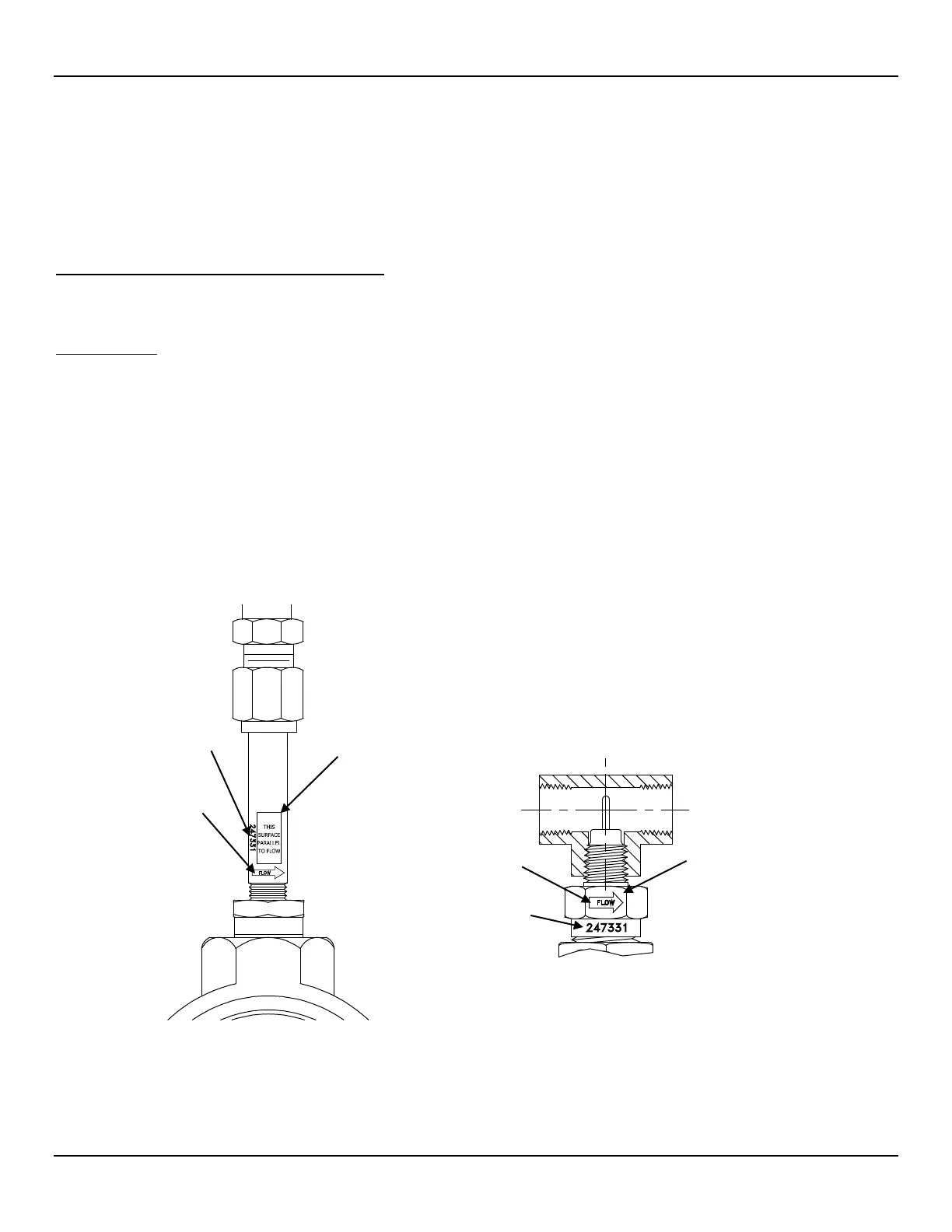

All sensor elements have a flow arrow indicator marked on the element assembly at the reference flat, which indicates the flow direction for

which the flow element has been calibrated. Install the instrument with the flow arrow facing in the same direction as flow in the pipe

stream as shown in Figure 3 and Figure 4. The ST75A/ST75AV flow element has been calibrated directly in the pipe tee or tube tee for

orientation and insertion depth, as shown on Figure 4. See APPENDIX A, page 73 for orientation details.

Figure 1 – Probe Serial Number, Reference Flat and Flow Direction Mark

REFERENCE FLAT

REFERENCE HEX FLAT

Loading...

Loading...