INSTALLATION ST51A/ST75A/ST75AV Mass Flow Meters

8 Fluid Components International LLC

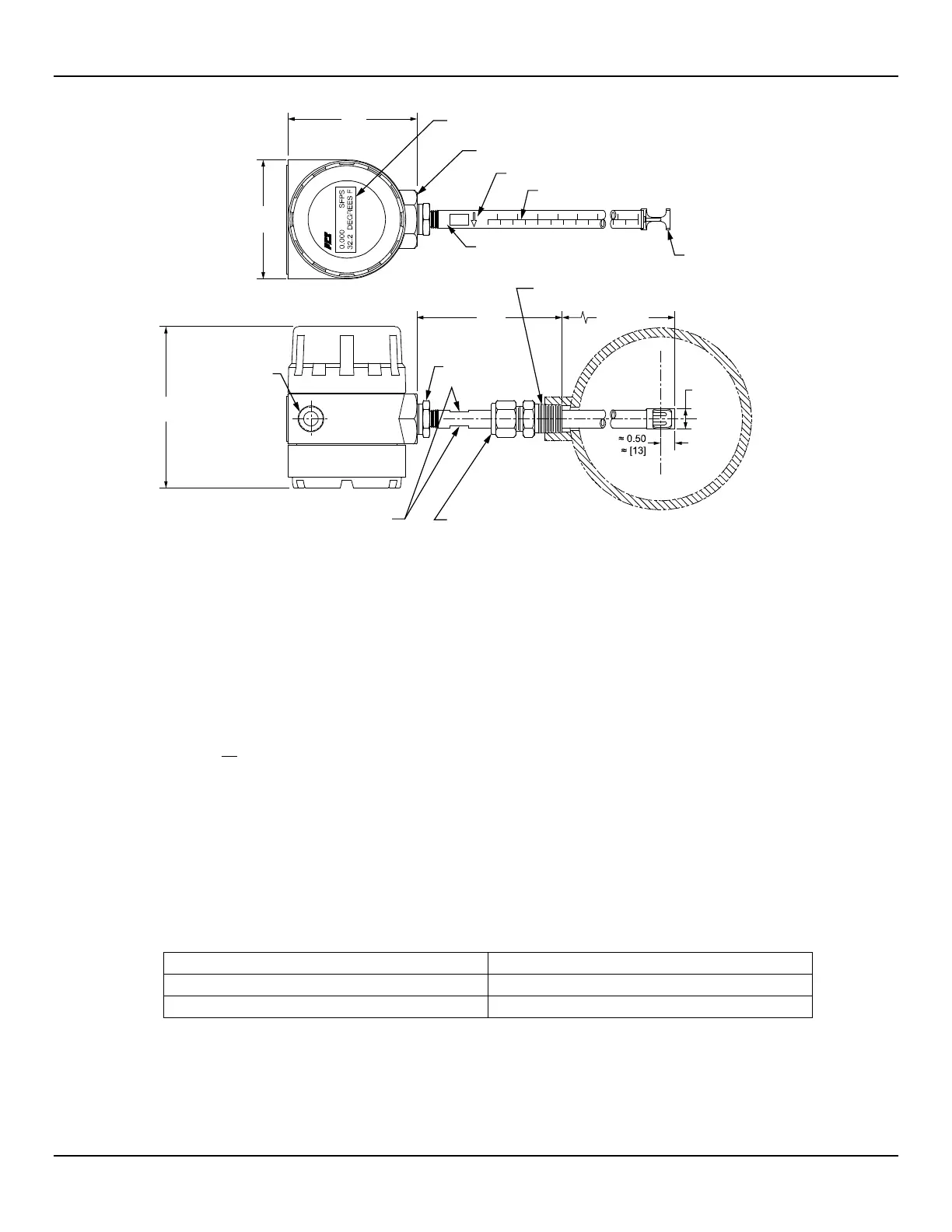

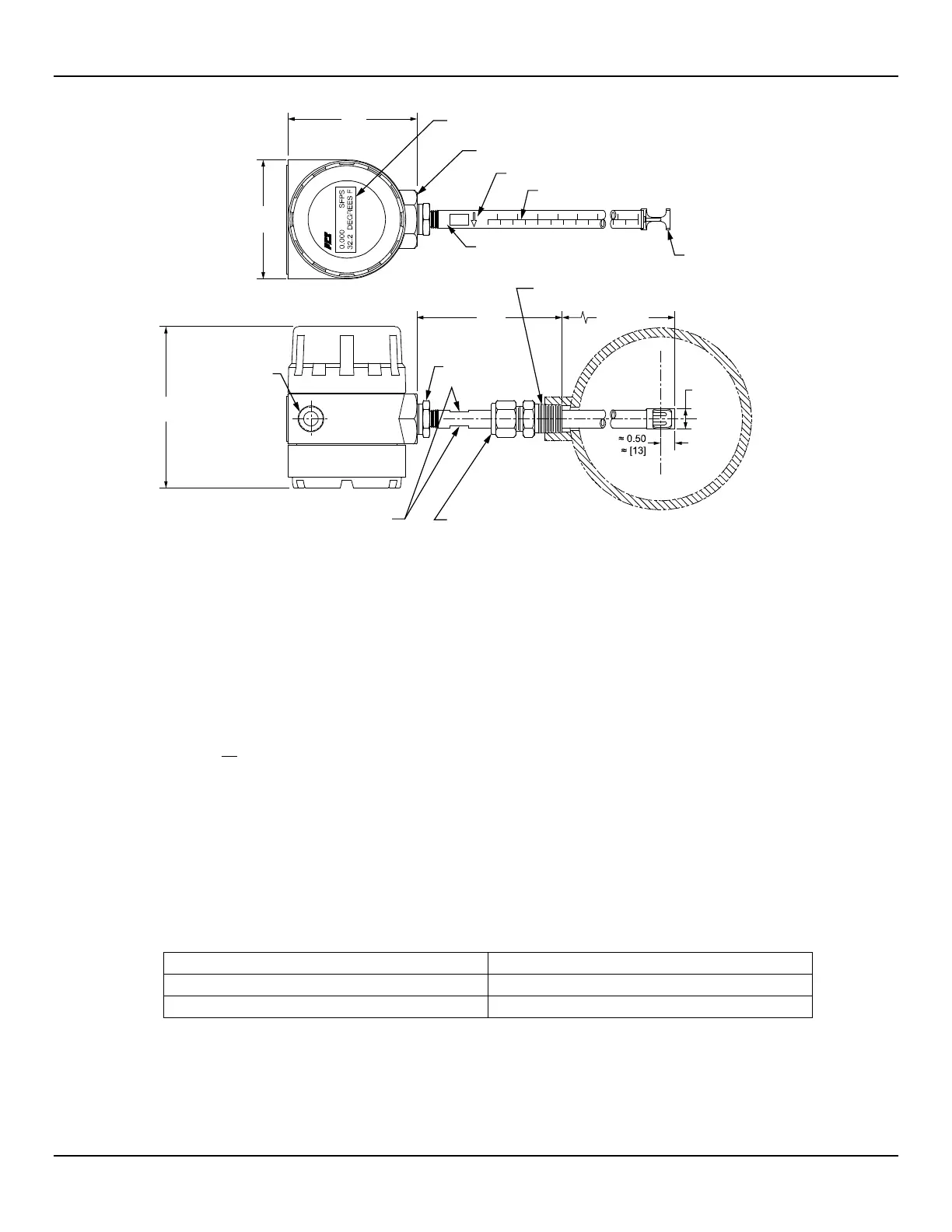

Figure 5 – Flow Element Installation, Compression Fitting ST51A

The flow element is properly mounted when the tip of the flow element is located 0.50 inches (13 mm) past the pipe centerline. The scale

etched on the side of the insertion pipe indicates the length to the tip of the flow element. Follow the steps below to install the ST51A flow

element.

1. Calculate the insertion depth using the equation below.

I = Insertion depth

I.D. = Pipe inside diameter

T = Pipe wall thickness

C = Pipe mounting coupling and compression fitting (installed length)

= 0.50" +

..

+ +

I = __________

2. Mark the insertion pipe at the calculated insertion depth.

3. Apply proper thread sealant to the tapered pipe thread on the compression fitting and secure into pipe mounting coupling.

4. Insert the flow element to the insertion depth mark making sure the orientation flat is aligned parallel to the flow direction. Hand tighten

the compression nut. Compression fitting manufacturer recommends 1-1/4 turns past hand tight.

5. Tighten the compression nut to the torque specified for the corresponding ferrule material as shown in Table 2 below.

Table 2 – Compression Fitting Material

The metal ferrule configuration can only be tightened one time. Once tightened, the insertion length is no longer

adjustable.

XXXX

FLUID COMPONE NTS

INTERN A TIONAL LLC

y

C00584-1-3

MOUNTING ORIEN TATION OF FLATS

TO BE PARALLEL TO FLOW

2X 1/2" NPT,

OPTIONA L M20 x 1.5

ADJUSTABLE COMPRESSION FITTING,

OPTIONA L TEFLON OR METAL FERRULE

ENCLOSURE MEETS EXPLOSION PROOF

WATER AND DUST TIGHT APPRO VALS

OPTIONA L DUAL LINE DIGITAL DISPLAY,

90° INCREMENTAL ROTATION

1/2 OR 3/4 INCH NPT

PROCESS CONNECTION

FLOW ARROW

LASER ETCHED INSERTION SCALE

SERIAL NUMBER

REDUCER

BUSHING

PROTECTIVE SHROUD

OVER PROBE TIPS

0.56

[014]

4.00

[102]

U LENGTH

VARIABLE

4.5

[114]

3.28

[83]

3.56

[90]

L

C

Loading...

Loading...