69

EN

Theaxlenutsmustbecorrectlyfastened

after each chain adjustment process.

Work may only be performed on the

chain once the electrical system has

been switched o and the battery has

been removed. If the chain of your

FLYER e-bike has fallen o the chain

ring or sprocket, it is essential to switch

otheelectricalsystemandremovethe

battery before placing the chain back on

the gear wheels.

Chain care

The drive chain must be cleaned and lubricated

regularly in order to ensure that it functions well

(see section “Inspection plan”).

Dirtcansimplybewashedo.Youcanalsoclean

the chain by wiping it with an oil-soaked cloth.

Once it is clean, it must be lubricated at the joints

with a suitable lubricant. After leaving for a short

while,wipeotheexcesslubricant.

Belt drive

The Gates Carbon Drive belt is very durable and

long-lasting. However, you must take extreme

care before and during assembly to ensure that

no damage is caused to the carbon bres that

make upthestrength of the drive belt. Extreme

bending and twisting causes tears that can lead to

faults in the belt if subjected to high stress.

1

10-15 mm

2

3

Follow the instructions for handling the Gates

Carbon Drive System belt and observe the provi-

sions in the user manual.

Drive belt and chain tighten if the bike has

sliding dropouts

Adjusting the tension and alignment of

thebeltrequiresagreatdealofexperi-

ence. Improper handling can cause acci-

dents and severe falls. Always let your

FLYER specialist retailer perform this

activity.

If the tension of the drive belt is too low,

this can cause it to slip on the toothed

pulley. This may result in accidents or

severe falls.

The carbon bres inside the drive belt

may also be damaged. If the drive belt

slips through, take it to a specialist to be

checked over.

If the tension of the drive belt is too high,

bearings and seals in the wheel hub can

become damaged. The wear and friction

losses on the entire drive are therefore

also higher.

Thecarbon bresinsidethedrivebelt mayalso

be damaged. If the drive belt slips through, take it

to a specialist to be checked.

If the tension of the drive belt is too high, bearings

and seals in the wheel hub can become dam-

aged. The wear and friction losses on the entire

drive are therefore also higher.

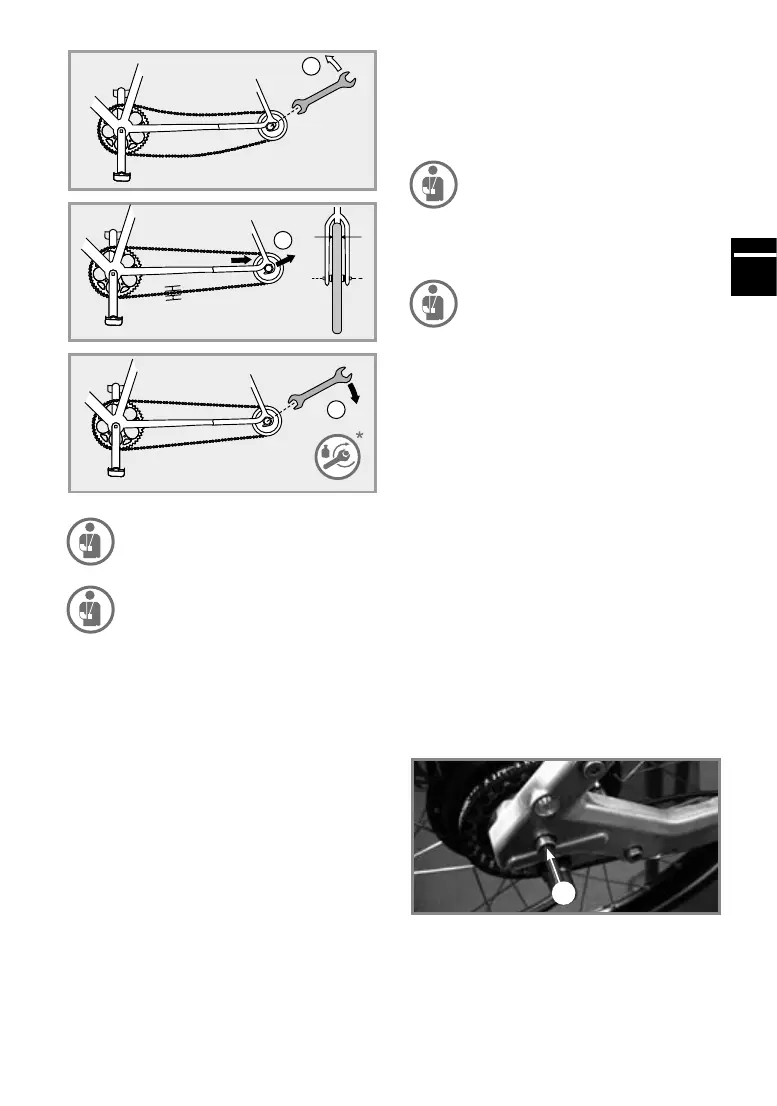

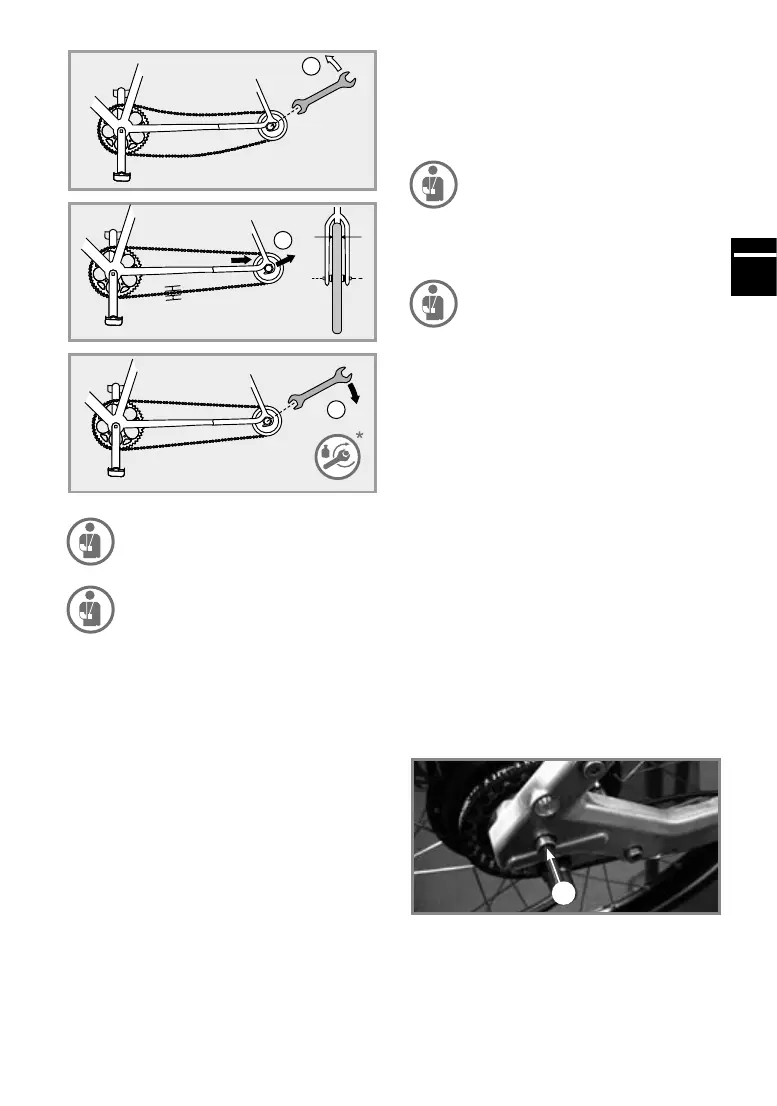

Tightening the toothed belt

Loosen the screws A1 on both sides of the dro-

pout. You only need to loosen the

screws until the dropout can move freely.

A1

Tighten the chain/toothed belt using the adjusting

screw A2. You have reached the correct chain

tension when the chain is still able to move up

and down slightly in the centre (10-15 mm). Use

a belt tension measuring device to check that the

belt tension is correct. Consult the belt manufac-

Loading...

Loading...