Hotstart func-

tion

To obtain optimum welding results, it will sometimes be necessary to adjust the

hotstart function.

Benefits

-

Improved ignition, even when using electrodes with poor ignition properties

-

Better fusion of the base material in the start-up phase, meaning fewer cold-

shut defects

-

Largely prevents slag inclusions

See the "Set-up menu: level 2" section for details on setting the available welding

parameters.

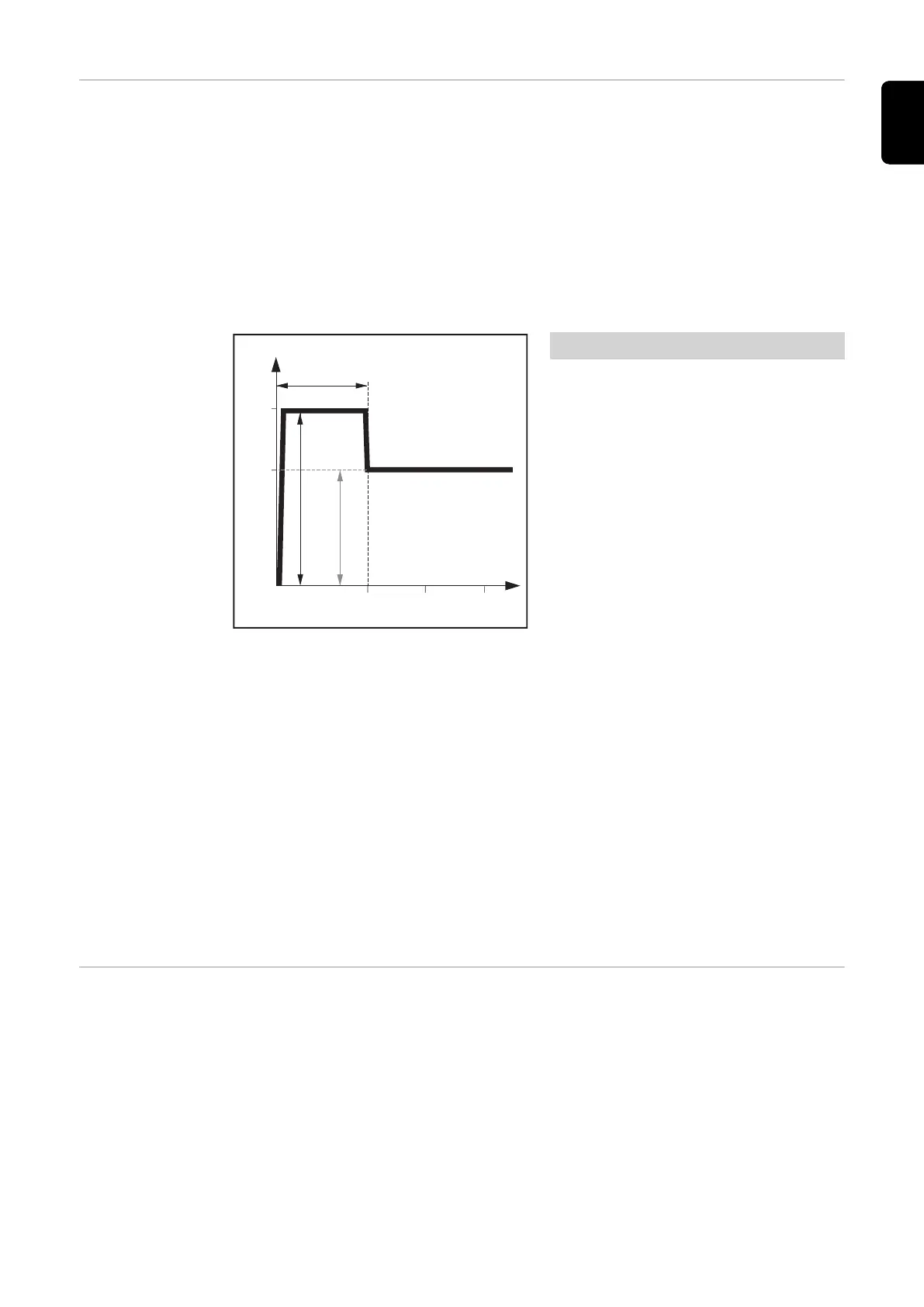

I (A)

t (s)

0,5 1 1,5

Hti

I

1

HCU

100

150

Example of hotstart function

Legend

Hti Hot-current time, 0-2 s, fact-

ory setting: 0.5 s

HCU HotStart current, 0-200%,

factory setting 150%

I

1

Main current = set welding

current

Function:

during the specified hot-current time

(Hti), the welding current I

1

is in-

creased to the HotStart current HCU.

To activate the hotstart function, the

HotStart current HCU must be > 100.

Settings examples:

HCU = 100

The HotStart current corresponds to the set welding current I

1

.

The hotstart function is not activated.

HCU = 170

The HotStart current is 70% higher than the set welding current I

1

.

The hotstart function is activated.

HCU = 200

The HotStart current is twice the set welding current I

1

.

The hotstart function is activated, the HotStart current is at its maximum.

HCU = 2 x I

1

Anti-stick func-

tion

As the arc becomes shorter, the welding voltage may drop so far that the rod

electrode will tend to stick. This may also cause the rod electrode to burn out.

Electrode burn-out is prevented by activating the anti-stick function. If the rod

electrode begins to stick, the power source immediately switches the welding

current off. After the rod electrode has been detached from the workpiece, the

welding process can be continued without any problems.

The anti-stick function can be activated and deactivated in the "Set-up menu -

level 2" section.

71

EN

Loading...

Loading...