The value set for G-H only applies if the maximum welding current actually has

been set. The actual value is derived from the present welding current. For a

medium welding current, for example, the actual value will be half of the value

set for G-H.

IMPORTANT! The values set for the G-L and G-H set-up parameters are added

together. For example, if both welding parameters are set to the maximum (40

s), the gas post-flow will last:

-

40 s at minimum welding current

-

80 s at maximum welding current

-

60 s if the welding current is exactly half the maximum, etc.

If Aut is set, the gas post-flow time G-H is calculated automatically.

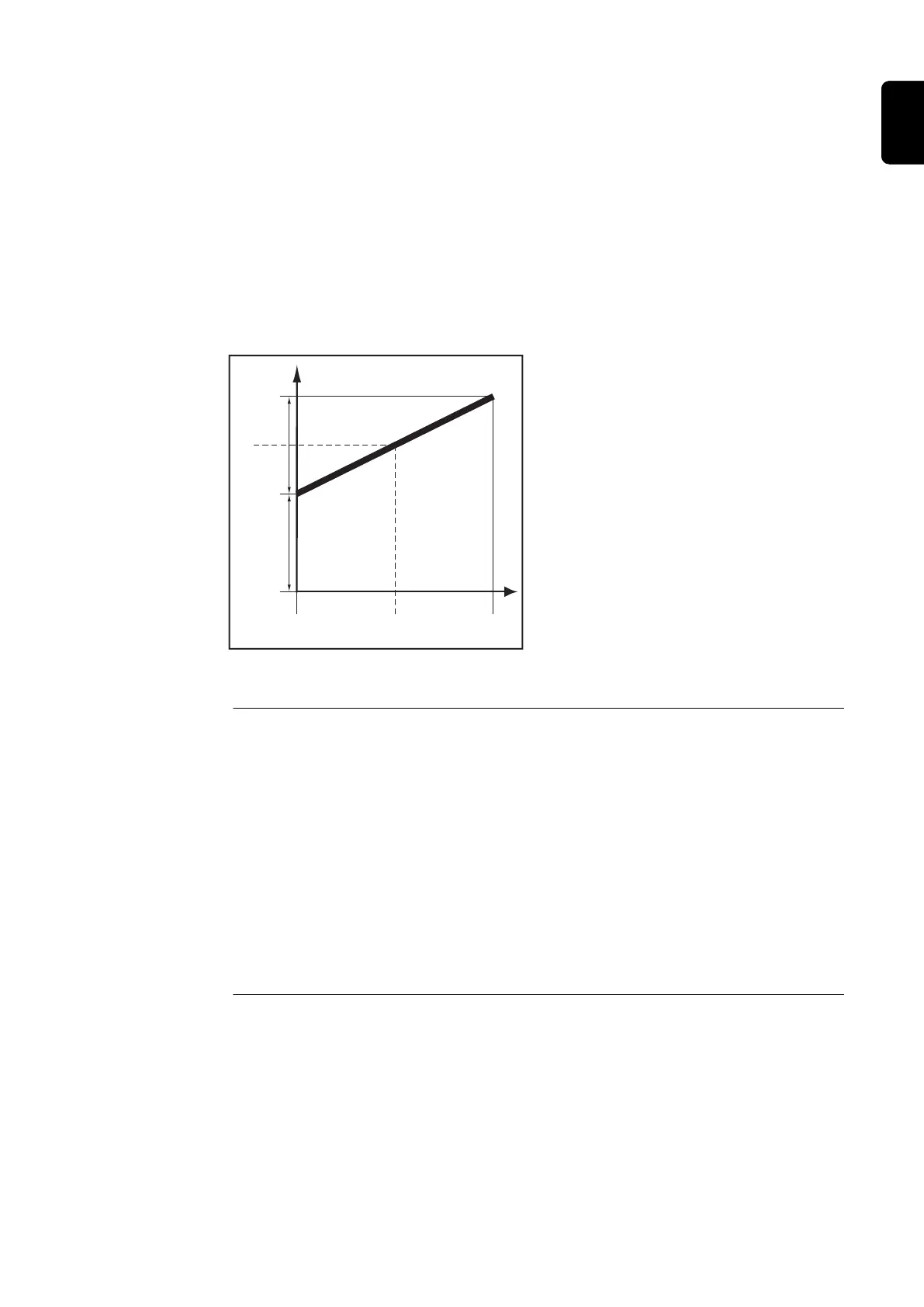

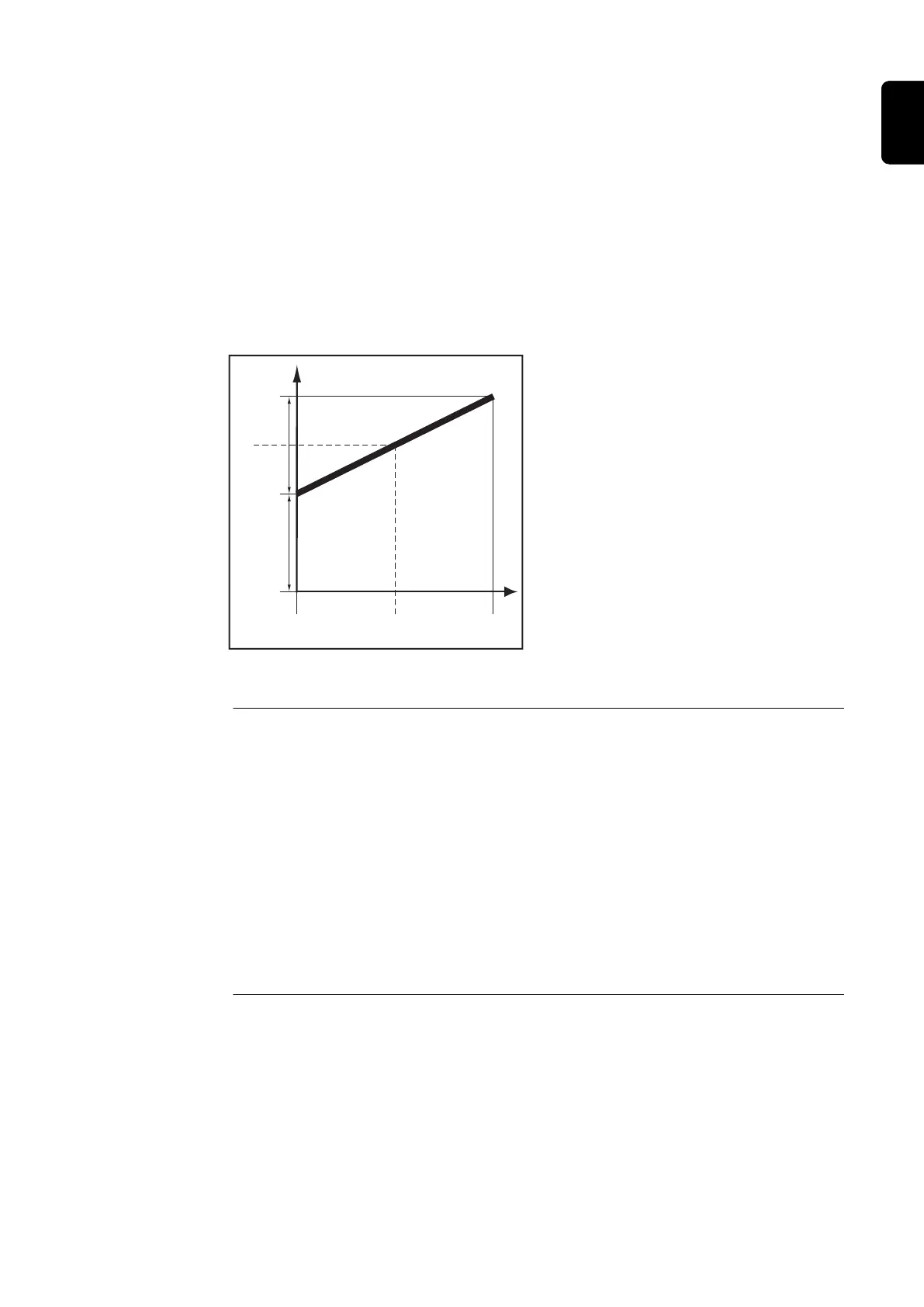

Legend:

(1).... Gas post-flow time at any given

moment

(2).... Welding current at any given

moment

Gas post-flow time as a function of the welding current

GPU

Gas purger - protective gas shield purging

Unit min

Setting range OFF / 0.1 - 10.0

Factory setting OFF

Purging of the protective gas shield begins as soon as GPU is allocated a value.

For safety reasons, purging of the protective gas shield cannot be restarted un-

til a new GPU value is entered.

IMPORTANT! Purging of the protective gas shield is necessary if condensation

forms when the device is left unused in a cold environment for a prolonged

period. Long hosepacks are most affected.

77

EN

Loading...

Loading...