70

5 Damage prevention

5.5 Painting work

MITSUBISHI FUSO body/equipment mounting directives for FE Issue date: 20. 10. 2020

! Only print out complete sections from the current version

5.5.5 Procedure for painting plastic parts

• Do not paint, bake or dry plastic parts of the cab

while they are installed. Remove plastic parts and

paint them as described below. It is recommended

that you use the paint and painting method

indicated in the table below.

Note 1. Acrylic lacquer type paint may be prone to blistering. For details, ask the paint manufacturer/supplier.

Note 2. Be sure to sand the surfaces before repainting, otherwise the paint film may not adhere well.

Note *1: The Iwata cup:

is a simple paint viscometer, viscocity cup, NK-2 produced by ANEST IWATA Corporation.

• Custom vehicles and optional plated parts cannot

be repainted.

• Solvent for removing contamination

Synthetic resin used for the grille, and so on, do not

readily withstand organic solvents. For this reason,

if you select the wrong kind of solvent for wiping

such a part, cracks may occur and also marks may

remain on the surface of the part.

• Organic solvents which can be used

• Kerosene

•Light oil

• Anti-freeze

• Wax spray can (Nihon Parkerizing Co., Ltd.) Neo

lider

• Industrial soap

•Unigold

•Car Spray 99

• Solvents which must not be used

• Paint thinner

•Turpentine

•Gasoline

•Escort

• Origin veil

•Torepika

• Emulsion wax

• Commercially available wax

•Acetone

• Reagent alcohol (The Japanese Pharmacopoeia

Grade 1)

• Ketones

•Esters

• Chlorinated hydrocarbon

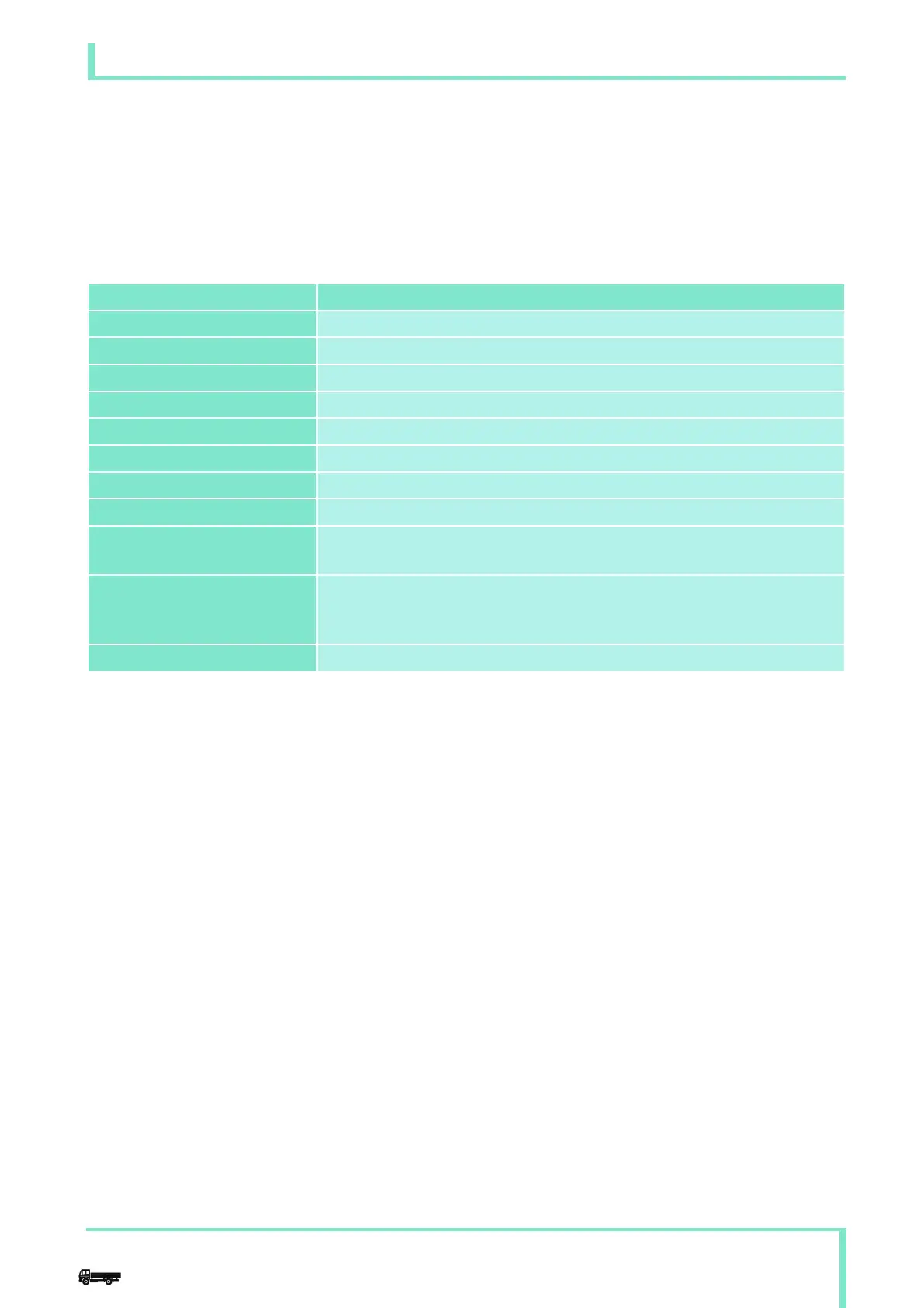

Paint manufacturer Dai Nippon Toryo Co., Ltd.

Paint type Acrylic and urethane type

Name of paint Planitto #3000

Curing agent Planitto #721 curing agent

Blending ratio Main ingredient : Curing agent = 100 : 15

Diluting thinner Planitto #30 thinner

Paint viscosity 12 – 14 seconds/by the use of Iwata cup

*1

Dry film thickness 20 – 35 µ

Setting Normal temperature × 5 – 10 minutes

Drying the paint film 60 – 70° × 30 – 40 minutes

Touch-drying ≈ 15 – 20 minutes

Pre-treating the surface to be

painted

1. Sanding white painted surfaces

2. IPA degreasing

3. Air blow

Painting method Hand spraying with gun

Loading...

Loading...