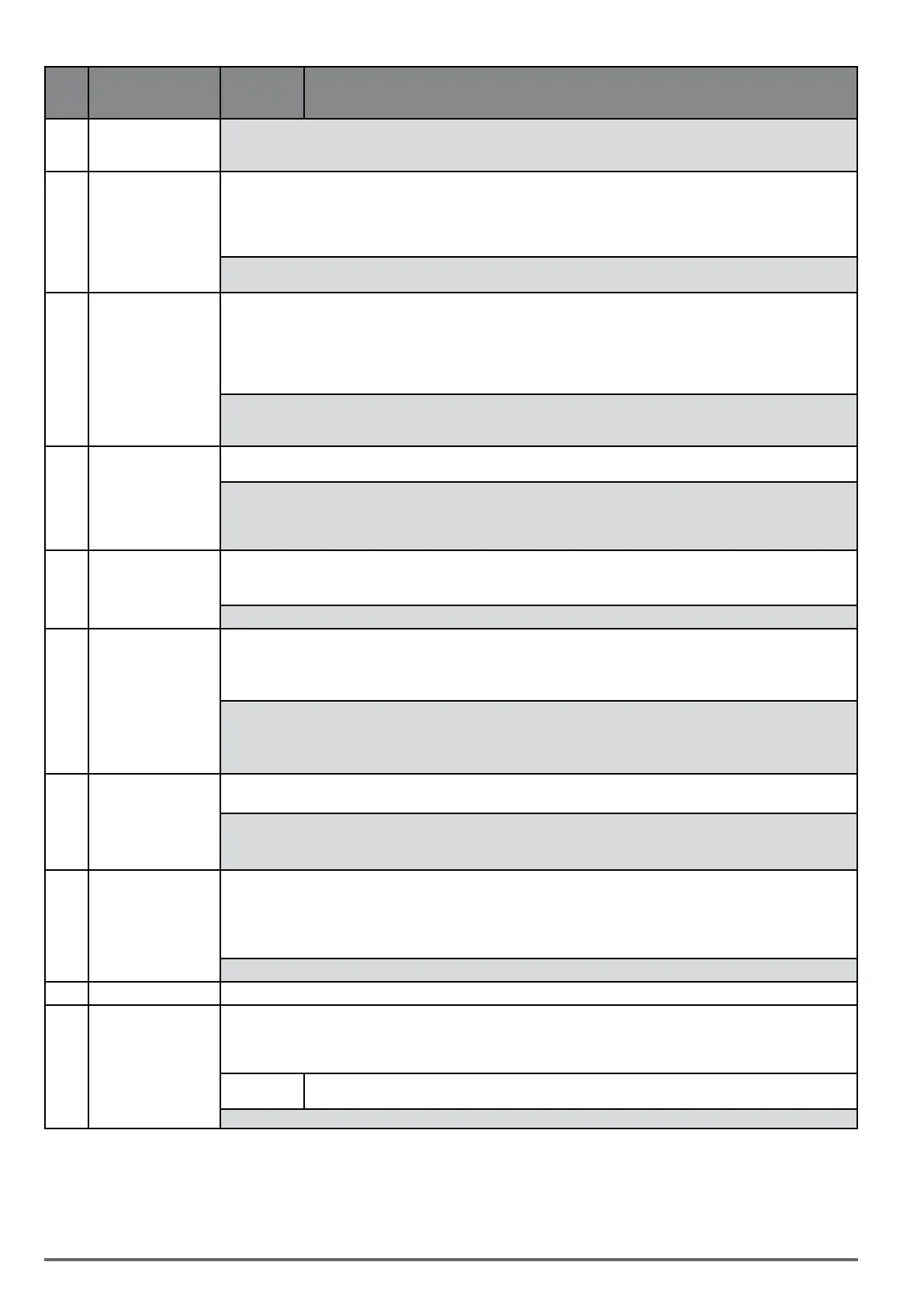

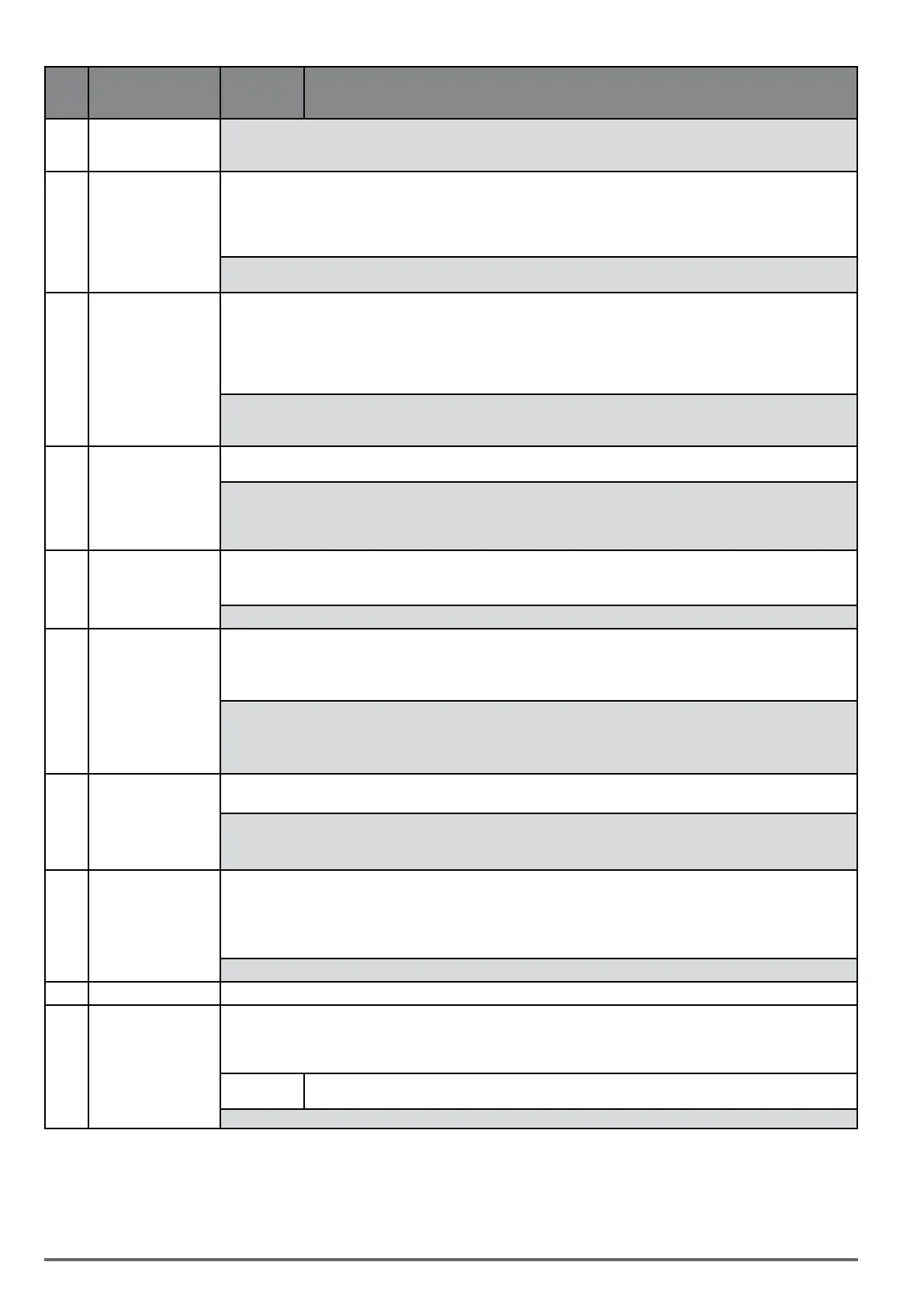

64 ADV200 SP • Quick start up guide - Specification and installation

Code Error message shown

on the display

Sub-code Description

Solution:

- Limit the speed reference.

- Check that the motor is not driven in overspeed during rotation.

24 Speed ref loss

Condition: Speed reference loss alarm

Occurs if the difference between the speed regulator reference and the actual motor speed is more than 100 rpm. This

condition occurs because the drive is in the current limit condition. It is only available in the Flux Vect OL mode.

Solution:

- Check the drive load conditions

25 Emg stop alarm

Condition: Emergency stop alarm.

The Stop key on the keypad was pressed with the PAR 1008 Stop key mode parameter set to EmgStop&Alarm.

Active in remote control mode (PAR 1012=1) both by using “Terminals” command or “Digital” commands and, in local

control mode (PAR 1012=0) by using “Terminals” command.

Solution:

Eliminate the reason for which the Stop key on the keypad was pressed and reset the drive.

26 Power down

Condition: The drive was enabled with no supply voltage at the power section.

Solution: Emergency stop alarm. The Stop key on the keypad was pressed with the Stop key mode parameter set to

EmgStop&Alarm in case of Remote->Terminal Strip or Remote->Digital or Local->Terminal Strip mode.

27 Broken belt

Condition: Occurs if torque required from motor falls below a programmed threshold (PAR 7702) and if speed exceeds

a programmed threshold (PAR 7706).

Solution: Check system mechanics.

28 End curve

Condition: The value of the feedback signal (for example, pressure transducer) is below the reference value and

rotation speed is higher than the threshold set in parameter 7712. The alarm is generated if this condition persists for

a time equal to the value set in parameter 7714

Solution:

• Check configuration of parameters on menu 26.11.

• Check for system leakages.

• Check the feedback sensor.

29

30

Dry pump

No flow

Condition: The value of delivered power (parameter 7752) is below the limits defined by the minimum power curve.

Solution:

• Check configuration of parameters on menu 26.11.

• Check for system leakages.

31 Clean alarm

Condition: If cleaning cycles are performed too frequently, there may be a problem with the pump that requires the

attention of an operator. In that case a specific alarm is generated. Only cleaning cycles that start following an exter-

nal event (digital signal) or analog measurement are considered for this alarm.

Solution: Check the system.

32

Not Used 6

33 ...

40

Plc1 fault

...

Plc8 fault

Condition: Enabled application developed in the IEC 61131-3 environment has found the conditions for generating this

specific alarm to be true. The meaning of the alarm depends on the type of application. For more information, refer to

the documentation concerning the specific application..

XXXXH-X The XXXXH-X code indicates the reason for the error: make a note of this to discuss it with the service

centre.

Solution: Refer to the documentation concerning the enabled application.

Loading...

Loading...