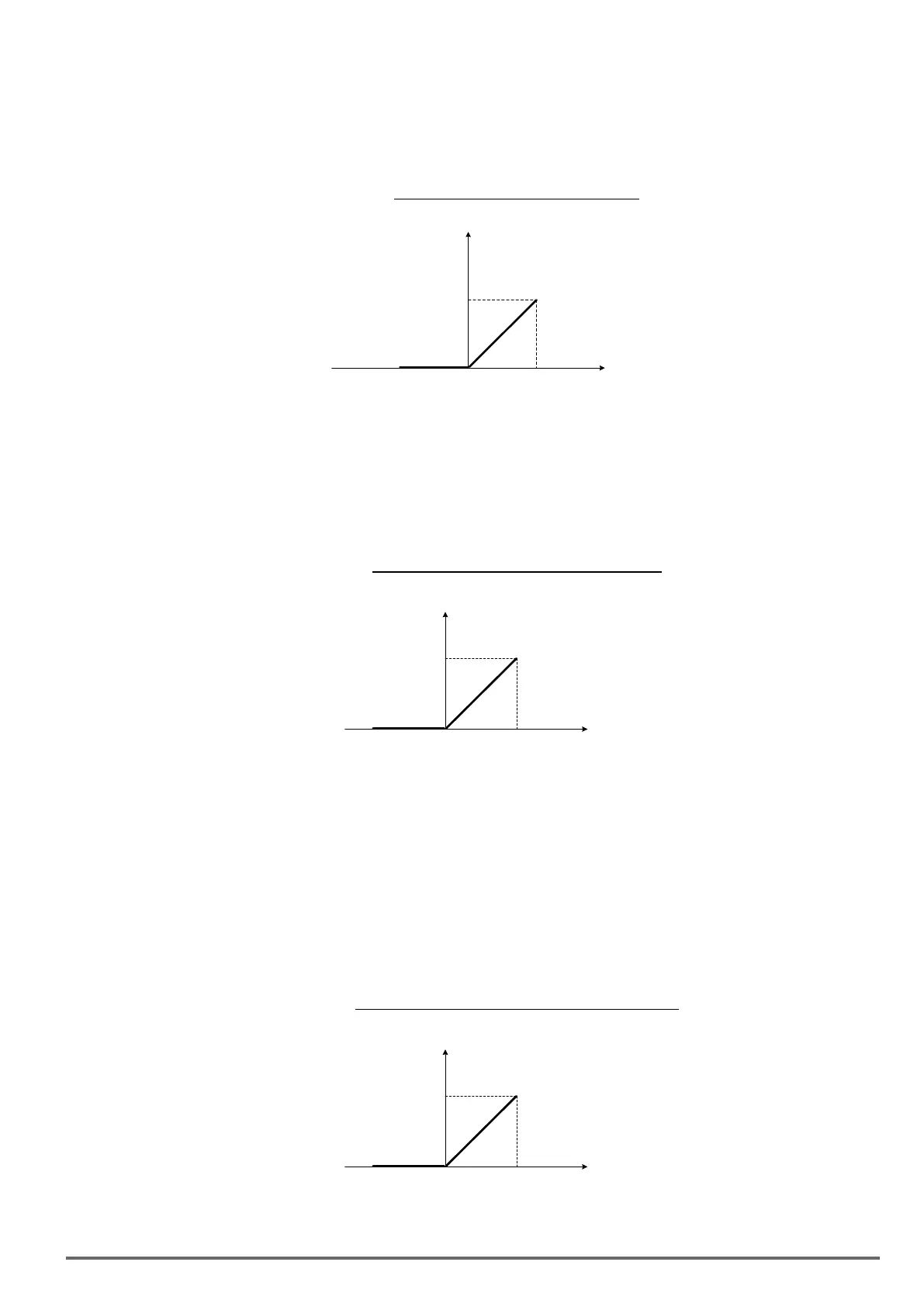

04-05=5: DC braking current

Multi-function analog input AI2 can be used to adjust the DC Injection braking current.

DC braking current parameter 07-07 setting should be set to 0% to use this function.

The inverter rated current = 100%

Figure4.4.44DCbrakingcurrentadjustment

100%

-10V

10V

(20mA)

0V

(4mA)

Braking

Current

Terminal AI2

analog input

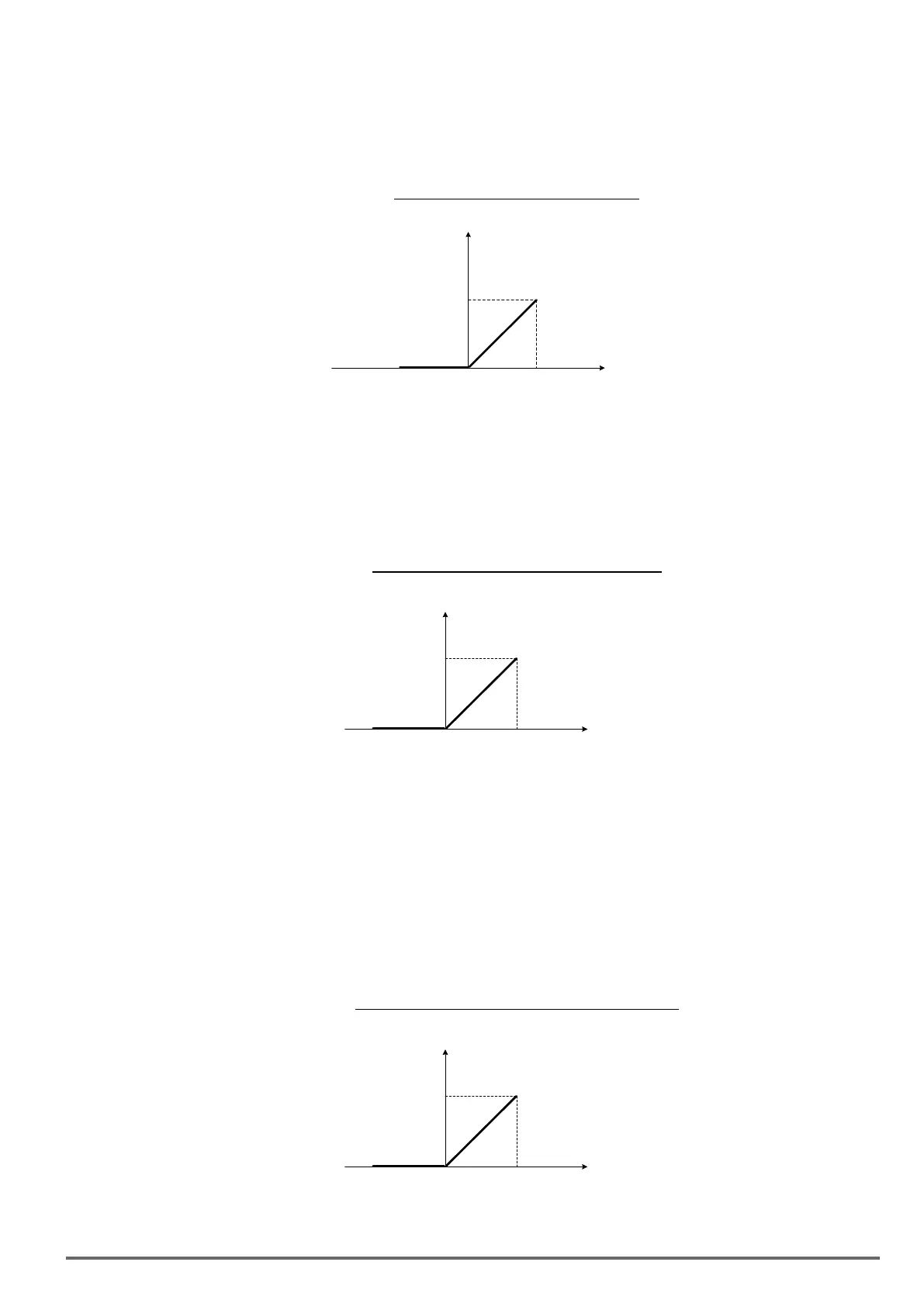

04-05=6: Over-torque detection level

Multi-function analog input AI2 can be used to adjust the over-torque detection level.

100% of inverter rated current (V/f or V/f + PG control mode)

100% motor rated torque (SLV or SV control mode)

If the multi-function analog input is used to adjust the over-torque level, the internal over-torque detection level

(08-15) is disabled.

Figure4.4.45Over-torquedetectionleveladjustment

100%

-10V

10V

(20mA)

0V

(4mA)

Level

Terminal AI2

analog input

4-05=7: Stall prevention level during running

Multi-function analog input AI2 can be used to adjust the stall prevention level during operation.

Inverter rated current = 100%. When AI2 is set to control stall prevention level (04-05 = 7) and parameter 08-

03 (Stall prevention level during operation) is used, then the lesser of the two value becomes the active stall

prevention level during operation.

Example: If the motor power is less than that of the inverter, the operation and the stall prevention of the motor

will be based on the factory settings, multi-function analog input AI2 can be used to reduce the stall prevention

level during operation.

Figure4.4.46Stallpreventionleveladjustmentinoperation

100%

-10V

10V

(20mA)

0V

(4mA)

Level

Terminal AI2

analog input

VDI100 • Instruction manual 177

Loading...

Loading...