What does OCd over current mean on gefran VDI100?

- CCaleb WoodwardSep 5, 2025

If your Gefran Inverter displays an OCd (Over Current) error, it's likely because the deceleration time is too short. To resolve this, set a longer acceleration time.

Loading...

Loading...

What does OCd over current mean on gefran VDI100?

If your Gefran Inverter displays an OCd (Over Current) error, it's likely because the deceleration time is too short. To resolve this, set a longer acceleration time.

What causes an OCC over current error on a gefran VDI100?

If your Gefran Inverter displays an OCC (Over Current) error, it might be due to an instantaneous change of load; in this case, change to a bigger size of inverter. It could also be due to an instantaneous change of current; try adding a reactor to the power source.

What to do if my gefran VDI100 Inverter shows an OPL output phase loss error?

If your Gefran Inverter displays an OPL (Output Phase Loss) error, it could be because the wiring is loose in the inverter output terminal; check the output wiring and tighten the screws. It could also be that the motor's rated current is less than 10% of the inverter's rated current; check the motor and inverter ratings.

What does IPL input phase loss mean on my gefran VDI100 Inverter?

If your Gefran Inverter displays an IPL (Input Phase Loss) error, it could be due to a few reasons. The wiring might be loose in the inverter input terminal, so check the input wiring and tighten the screws. There might be a momentary power loss, so check the power supply. Input voltage imbalance could also cause this, so check the power supply.

How to fix OH1 Heatsink overheat error on gefran VDI100?

If your Gefran Inverter displays an OH1 (Heatsink Overheat) error, it could be due to several reasons. The ambient temperature might be too high, so install a fan or AC to cool the surroundings. The cooling fan might have failed, so replace the cooling fan. The carrier frequency might be set too high, so reduce the carrier frequency. Also, the load might be too heavy, so reduce the load and measure the output current.

What does SC short circuit mean on gefran VDI100 Inverter?

An SC (Short Circuit) error on your Gefran Inverter can be caused by a short circuit or ground fault; check the motor wiring. It could also indicate a damaged motor (insulation); in that case, disconnect the motor and try running the inverter. Wire damage or deterioration can also cause this error; disconnect the motor and try running the inverter.

Why am I getting a UV Under voltage error on my gefran VDI100 Inverter?

If your Gefran Inverter is showing a UV (Under Voltage) error, it could be due to several reasons. The input voltage might be too low, so check the input voltage. There might be an input phase loss, so check the input wiring. The acceleration time might be set too short, so increase the acceleration time. Input voltage fluctuation could also be the cause, so check the power source. The pre-charge contactor could be damaged, so replace the pre-charge contactor. Also, the DC bus voltage feedback signal value might be incorrect, so replace the control board or the entire inverter.

What does OL2 Inverter overload mean on my gefran VDI100?

If your Gefran Inverter displays an OL2 (Inverter Overload) error, it could be due to a few reasons. The voltage setting in V/f mode might be too high, causing over-excitation of the motor; check the V/f curve. The inverter rating might be too small; replace the inverter with a larger rating. Finally, the load might be too heavy; check and reduce the motor load, and check the operation duty cycle.

What causes an OL1 Motor overload error on a Gefran Inverter?

If your Gefran Inverter displays an OL1 (Motor Overload) error, it could be due to a few reasons. The voltage setting in V/f mode might be too high, causing over-excitation of the motor; check the V/f curve. The motor rated current setting might be incorrect; check the motor rated current. Finally, the load might be too heavy; check and reduce the motor load, and check the operation duty cycle.

What causes a GF Ground fault error on my gefran VDI100?

If you're seeing a GF (Ground Fault) error on your Gefran Inverter, it could be due to several reasons. The motor might be damaged (insulation failure), so replace the motor. There could also be damage or deterioration to the wiring, so check the motor wiring. A defect in the inverter's DCCT sensors could also cause this; check the resistance between the cables and ground. Also, try reducing the carrier frequency.

Ensures correct wiring and warns against connecting input supply to output terminals.

Details proper grounding, RCD compliance, and dielectric withstand test precautions.

Covers model matching, carrier frequency adjustment for long cables, and cover installation.

Provides guidelines for safe inverter operation, including cover installation, motor connection, and fan operation.

Details procedures for maintenance, inspection, and replacement, emphasizing safety precautions.

Essential for verifying inverter nameplate and ensuring correct rating for application.

Lists inverter models and their corresponding applied motor power ratings for Heavy Duty applications.

Specifies operating temperature, storage, humidity, altitude, installation site, and shock conditions.

Details inverter installation in an upright position and required surrounding space for heat dissipation.

Illustrates the external appearance of different inverter sizes, labeling key components.

Highlights important warning information located on the front cover that must be read upon installation.

Explains how to remove the front cover to access terminals for wiring connections.

Provides UL approved wire gauges, crimp terminals, and fastening torque specifications.

Illustrates the basic power and control circuit terminal connections for the inverter.

Specifies terminal connections for input power, inverter output, and ground.

Provides wiring precautions, power input terminal details, and grounding requirements.

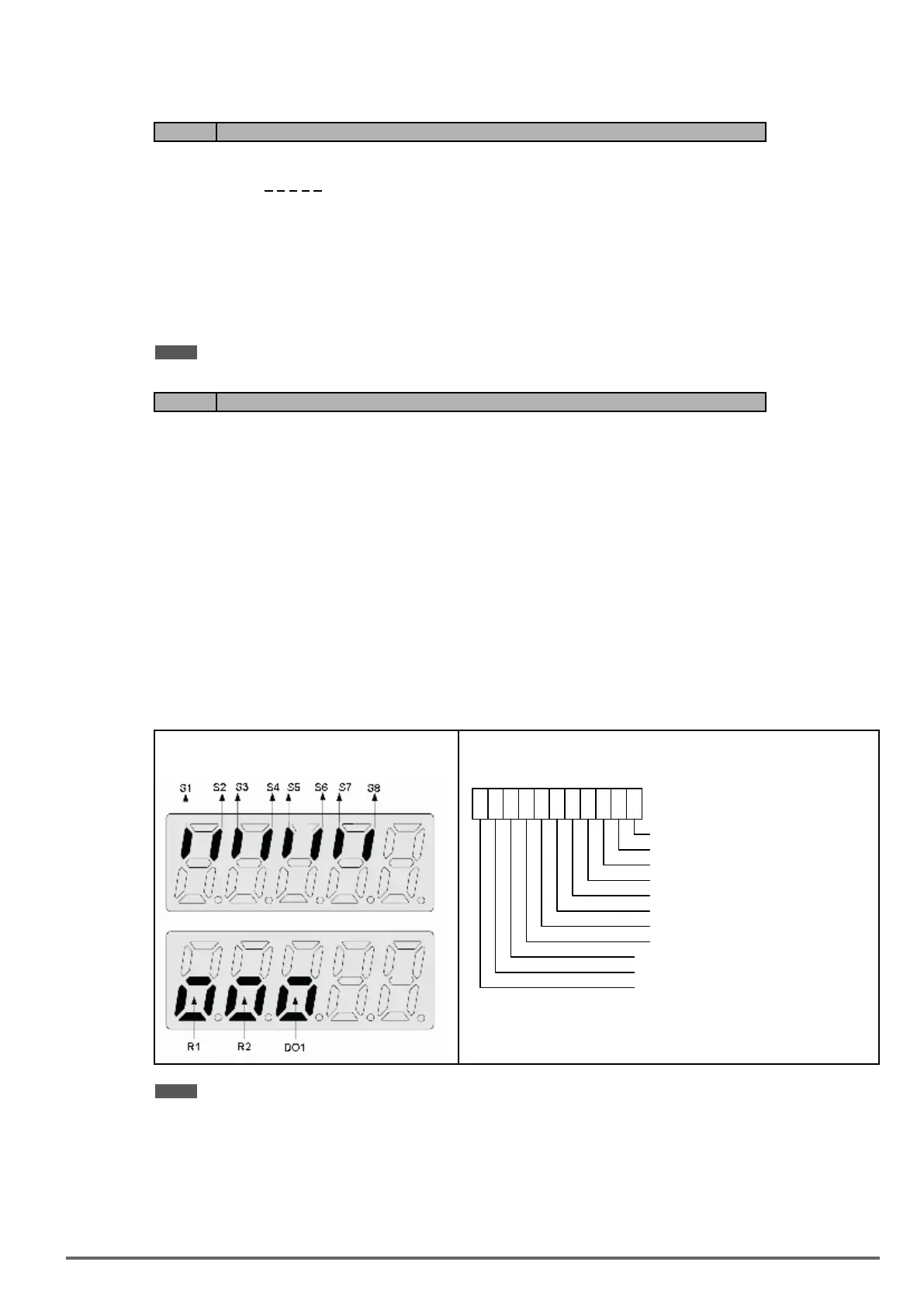

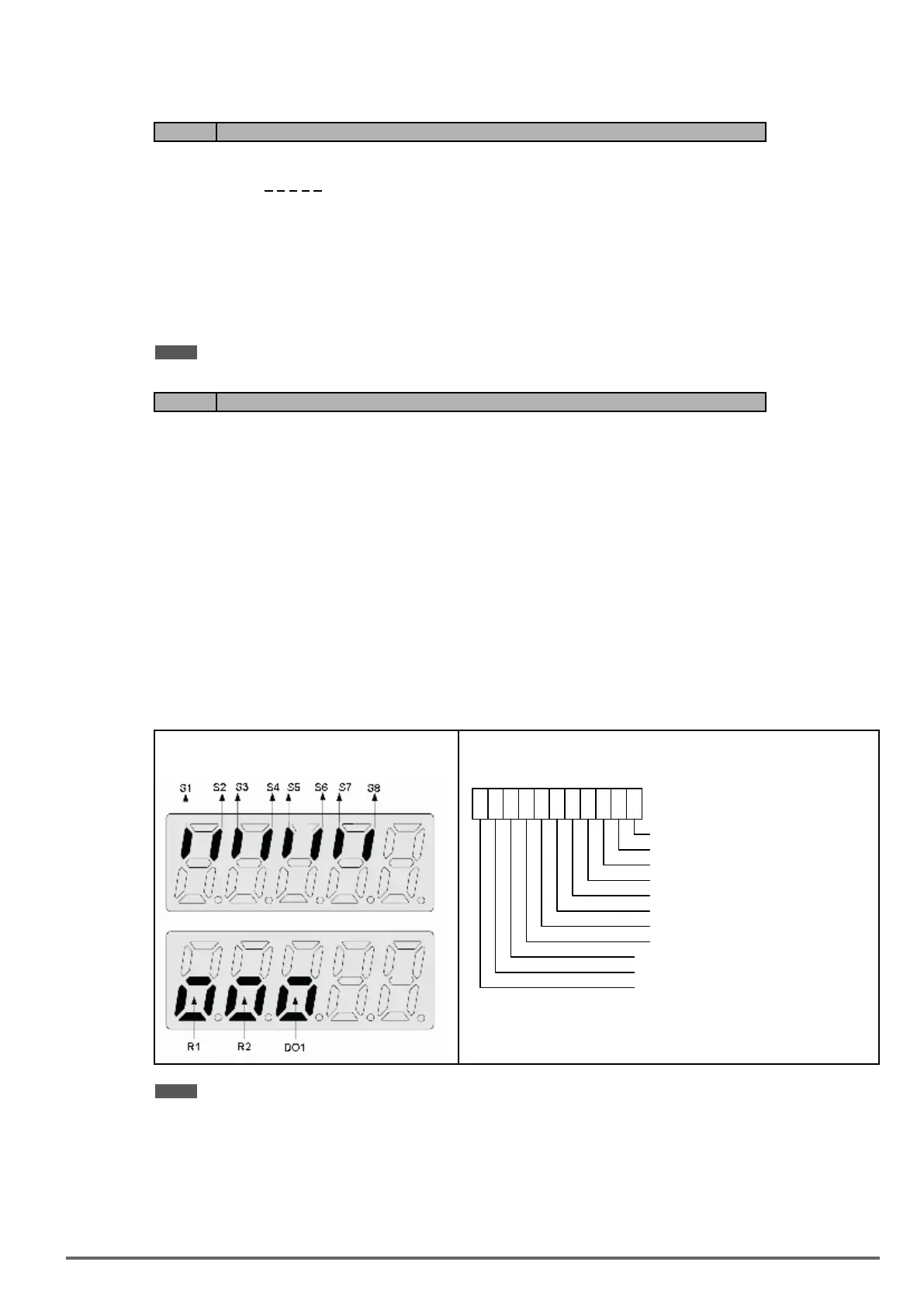

Details the LED keypad display, its keys, and their functions for inverter operation and parameter setting.

Explains the LCD keypad display, its keys, and the menu structure for programming and monitoring.

Provides a comprehensive list of all inverter parameters categorized into groups for easy access and configuration.