Maintenance Overview

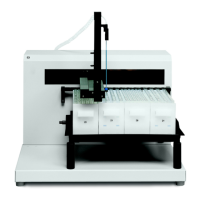

General guidelines for the periodic replacement of the ‘wear parts’ are indicated in the table

below, according to the amount of use: intensive, regular, or occasional. This schedule should

be regarded as a guide; changes in performance, or visible leaks, give an indication that a part

should be changed.

Component

Intensive

(168 h/week)

Regular

(40 h/week)

Occasional

(10 h/week)

Piston seals 4.5 months (3000 h) 1–1.5 years (2500 h) 2 years (1000 h)

Check valves 7 months (4500 h) 1.5 years (3000 h) 3 years (1500 h)

Piston assembly 9 months (6000 h) 2–3 years (5000 h) 4 years (2000 h)

These recommendations are based on the assumption that the pump is working at half its maximum

flow rate and pressure.

To prevent injury, observe good laboratory practices when handling solvents. Know the

physical and chemical properties. Refer to the Material Safety Data Sheets for the solvents

used.

Cleaning

Keep the pumps clean for peak performance. Always turn the power off to the pumps before

cleaning. Wipe the pumps with a soft cloth dampened with a mild detergent and disinfect as

needed.

40

MAINTENANCE | 333/334 HPLC PUMPS

MAINTENANCE OVERVIEW

Loading...

Loading...