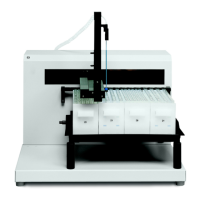

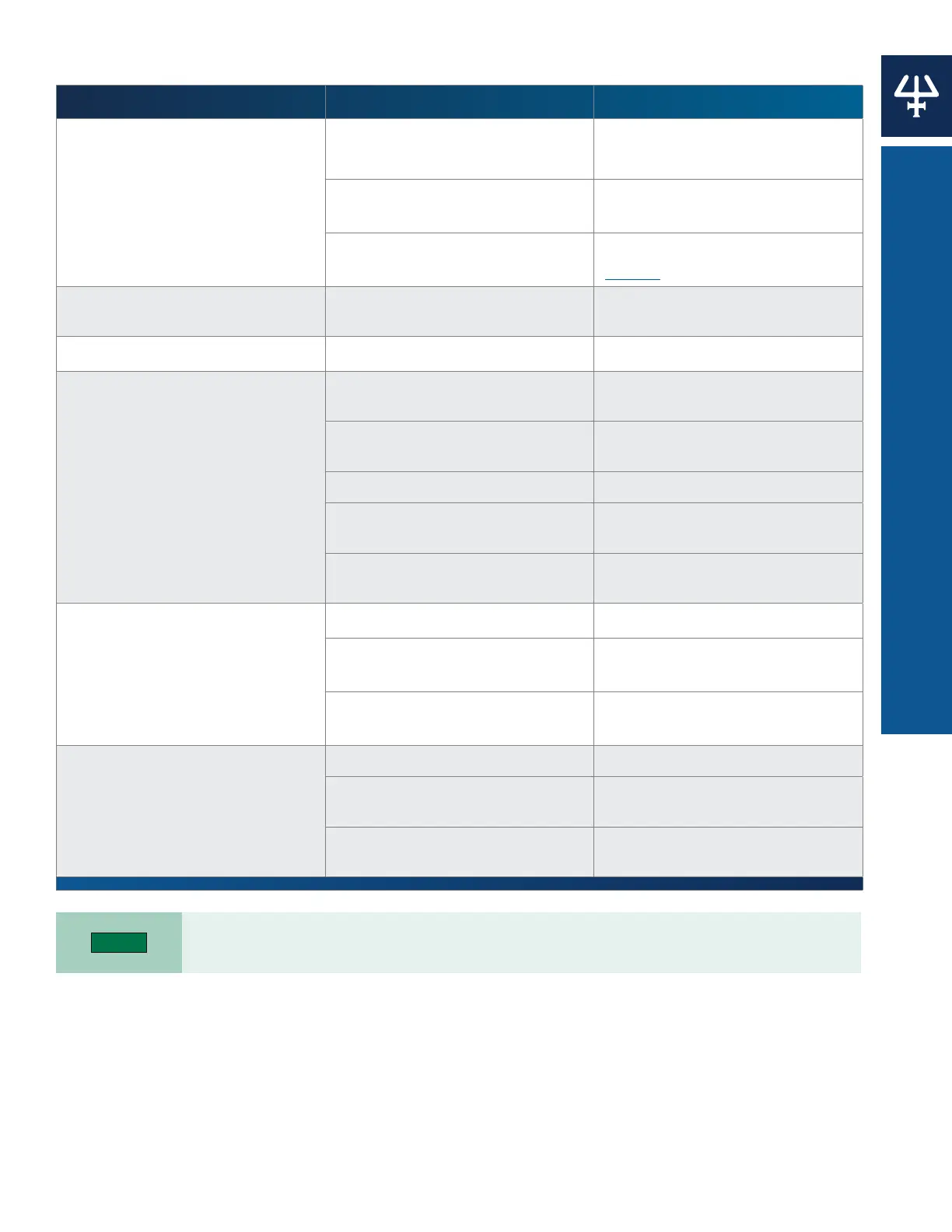

Hydraulic Problems

Problem Possible Causes Solutions

Air bubbles in both the inlet

and the outlet tubings

Inlet tubing is loose

Nut and/or ferrule damaged

Tighten the connectors

Replace the nut and/or ferrule

Inlet filter is plugged

Clean or replace the inlet

filter(s)

Refill time is too short

Increase the refill time; refer to

page 37

Air bubbles in the outlet tubing

only

Loose connection of outlet Tighten connectors

Leaks from a pump head Defective piston seal Replace the defective seal

Abnormally low flow rate

Leaks

Check the all plumbing for

leaks

Air entering upstream from the

head

Check the upstream

connections

Plugged inlet filter Replace inlet filter

Defective check valve

Clean or replace the check

valve

Incorrectly mounted pump

head

Remount the pump head

Abnormally high pressure

Plugged outlet filter Clean or replace outlet filter

Column particle size too small

or plugged column

Change or flush column

Mobile phase viscosity too high

Use lower viscosity solvents or

increase temperature

Baseline noise, periodic pulses

Mixer volume too small Increase mixer volume

Air in the hydraulics

Prime the pump, degas the

solvent

Faulty pressure module

Contact your Gilson

representative

Contact your local Gilson representative or techsupport@gilson.com for assistance resolving

problems described in this chapter.

57

333/334 HPLC PUMPS | USER’S GUIDE

TROUBLESHOOTING

Loading...

Loading...