-50-

Model G0776 (Mfd. Since 7/14)

Both the carriage and cross slide have power feed

capability when the carriage is engaged with the

feed rod. The rate that these components move

per revolution of the feed rod is controlled by the

quick-change gearbox dial positions and the end

gear configuration.

The feed per revolution and the spindle speed

must be considered together—this is the feed

rate. The sources you use to determine the opti-

mum spindle speed for an operation will also

provide the optimal feed to use with that spindle

speed.

Often, the experienced machinist will use the

feeds and speeds given in their reference charts

or web calculators as a starting point, then make

minor adjustments to the feed rate (and some-

times spindle speed) to achieve the best results.

The carriage can alternately be driven by the

leadscrew for threading operations. However, this

section only covers the use of the power feed

option for the carriage and cross slide compo-

nents for non-threading operations. To learn how

to power the carriage for threading operations,

refer to Threading on Page 55.

Power Feed

If the feed selection lever and the half nut

are engaged at the same time, machine

damage could occur. Even though there is

a lock-out device to prevent this, it could

break if forced.

Power Feed Controls

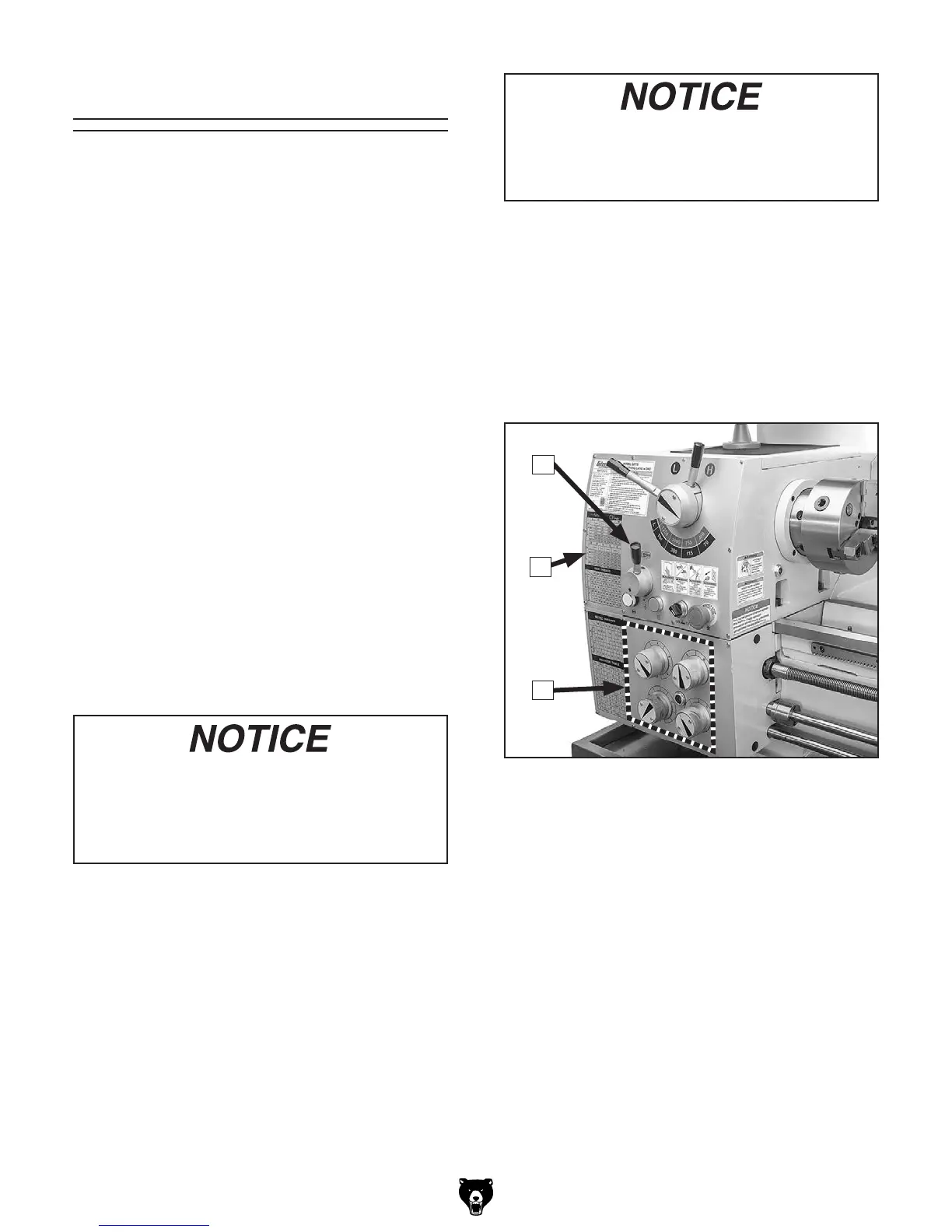

Use Figures 66–67 and the following descrip-

tions to understand the power feed controls.

Note: Before using power feed, you may have to

reconfigure the end gears, depending on how they

are set up. Refer to End Gears on Page 52 for

detailed instructions.

Figure 66. Power feed controls on the

headstock.

To avoid damaging the lathe, ALWAYS make

sure the spindle is completely stopped

BEFORE using the headstock controls to

make changes.

A. Feed Direction Lever: Selects the direction

for power feed. When the lever is positioned

as shown in Figure 66, the carriage will move

to the left along the bed, or the cross feed will

travel toward the front of the lathe.

B. Feed Rate Chart: Displays the settings

for the quick-change gearbox dials for the

selected feed rate. Refer to Setting Power

Feed Rate subsection on the next page for

detailed instructions.

C. Quick-Change Gearbox Dials: Position

these as indicated on the charts to choose

different feed rates.

A

B

C

Loading...

Loading...