-84-

Model G0776 (Mfd. Since 7/14)

Adjusting Spindle

Bearing Preload

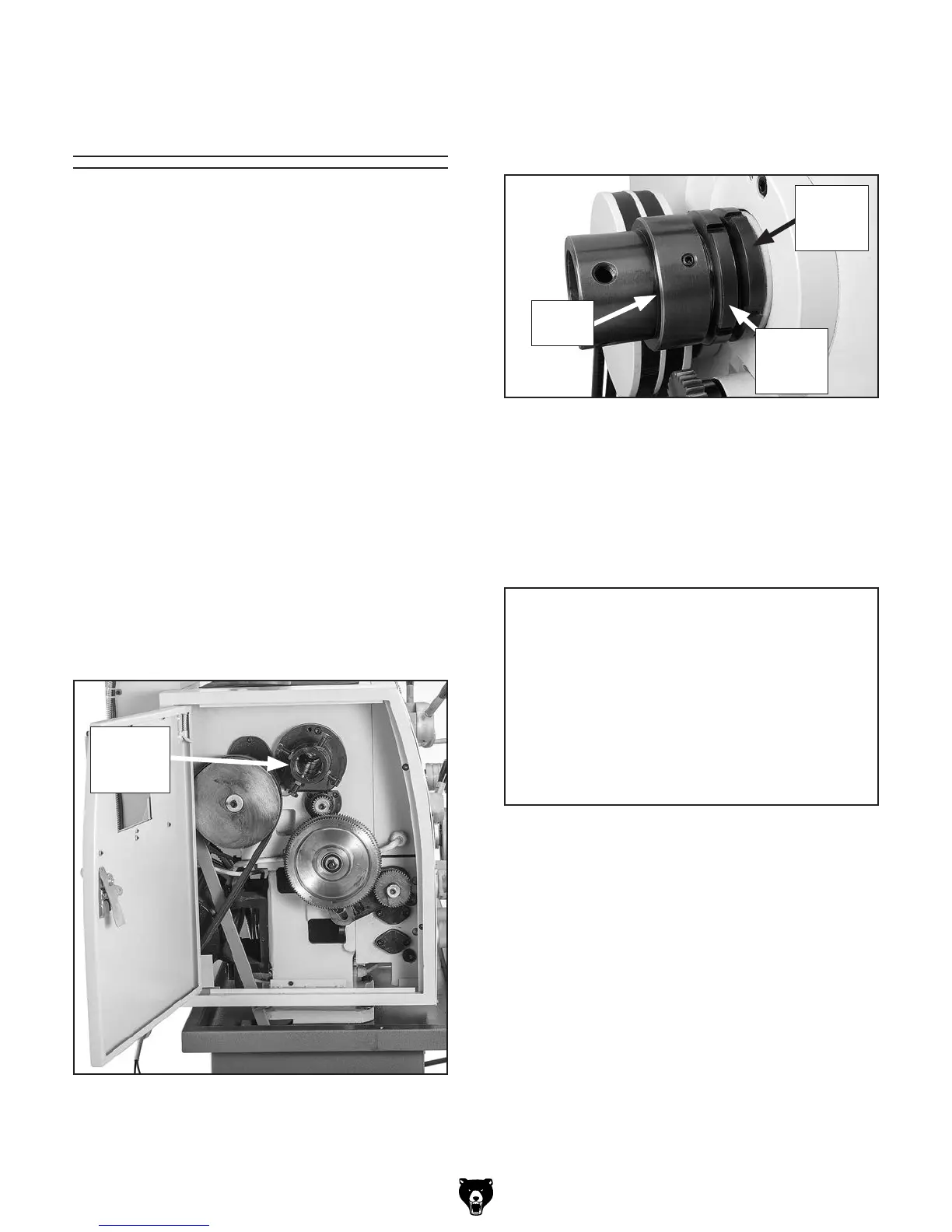

4. Place chuck wrench in camlock socket to

keep spindle from rotating, and loosen outer

spanner nut (see Figure 143) two turns.

Removing spider hub is not necessary.

Figure 143. Spindle spanner nuts.

Inner

Spanner

Nut

Outer

Spanner

Nut

Spider

Hub

5. Loosen inner spanner nut one turn.

Note: You may have to tap on the outboard

end of the spindle as explained in Step 6, to

help unload the spindle and break the span-

ner nut loose.

NOTICE

For the next step, DO NOT strike the wood-

en block with excessive force. If you do,

you can cause the tapered roller bearings

to indent the mating races. If this dam-

age occurs, one or more spindle bearings

will have to be replaced, as this damage

will generate vibration at higher spindle

speeds.

This lathe is shipped from the factory with the

spindle bearing preload set. If the spindle ever

develops end-play and the workpiece finish suf-

fers, you can re-establish the bearing preload,

remove the end-play, and correct the workpiece

finish issue.

Tools Needed Qty

Hook-Style Spanner Wrench 68-75mm ............. 1

Dial Indicator with Magnetic Base ..................... 1

Heavy Dead Blow Hammer ............................... 1

Wooden Block ................................................... 1

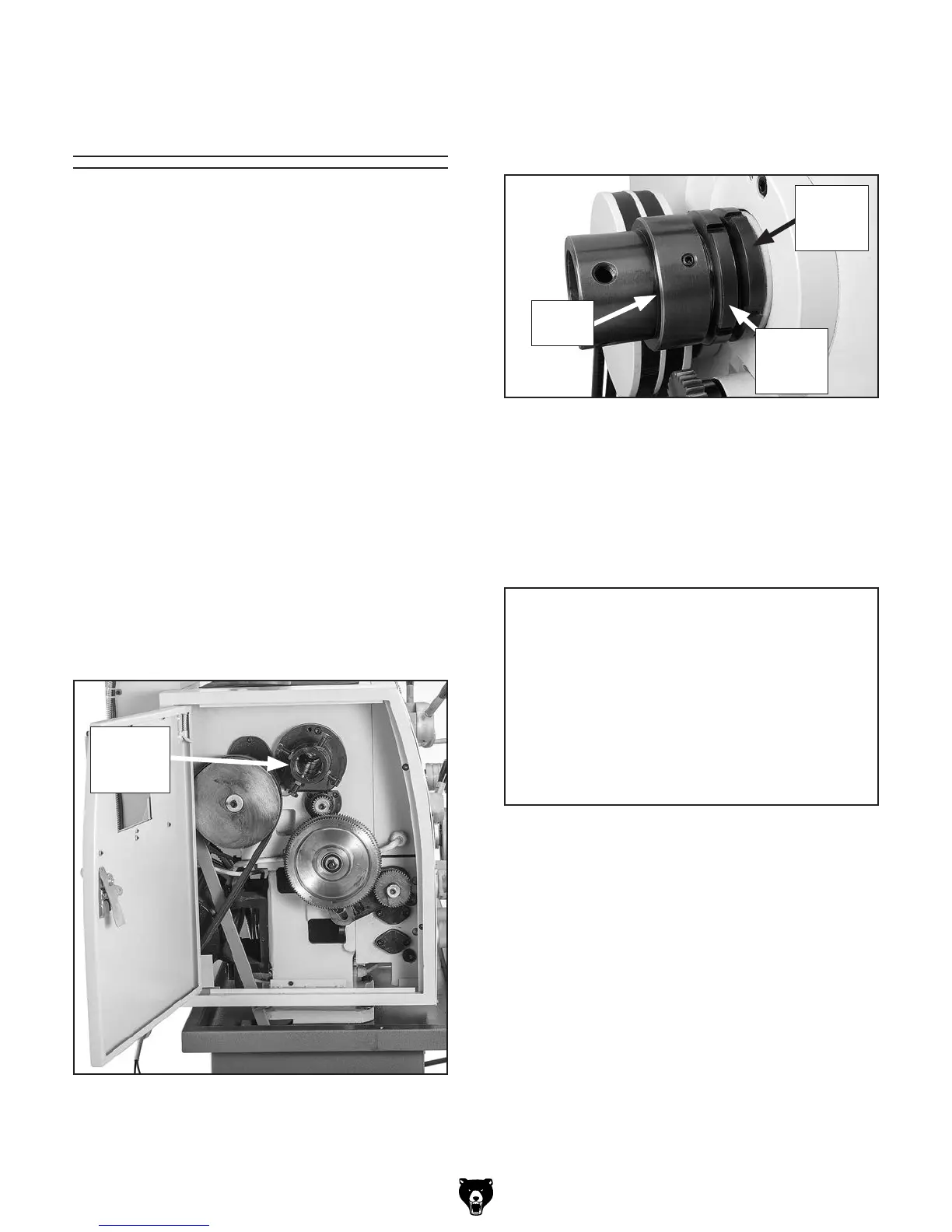

Figure 142. Location of outboard end of spindle.

Outboard

End of

Spindle

1. Run lathe for 20 minutes on high speed to

bring lathe to normal operating temperature.

2. DISCONNECT LATHE FROM POWER!

3. Remove chuck and spider bolts, then shift

spindle to neutral and remove headstock

gear cover to access outboard end of spindle

(see Figure 142).

Adjusting Preload

Loading...

Loading...