Model G0776 (Mfd. Since 7/14)

-83-

Tensioning/

Replacing V-Belts

V-belts stretch and wear with use, so check the

tension after the first three months and then every

six months to ensure optimal power transmission.

Replace all of the V-belts as a matched set if any

of them show signs of glazing, fraying, or crack-

ing.

Tensioning V-Belts

Tools Needed: Qty

Phillips Head Screwdriver #2 ............................ 1

Open-End Wrench 16mm .................................. 1

To tension V-Belts:

1. DISCONNECT LATHE FROM POWER!

2. Open end gear cover to expose V-belts, pul-

leys, and motor (see Figure 140).

Figure 140. End gear cover location.

End Gear

Cover

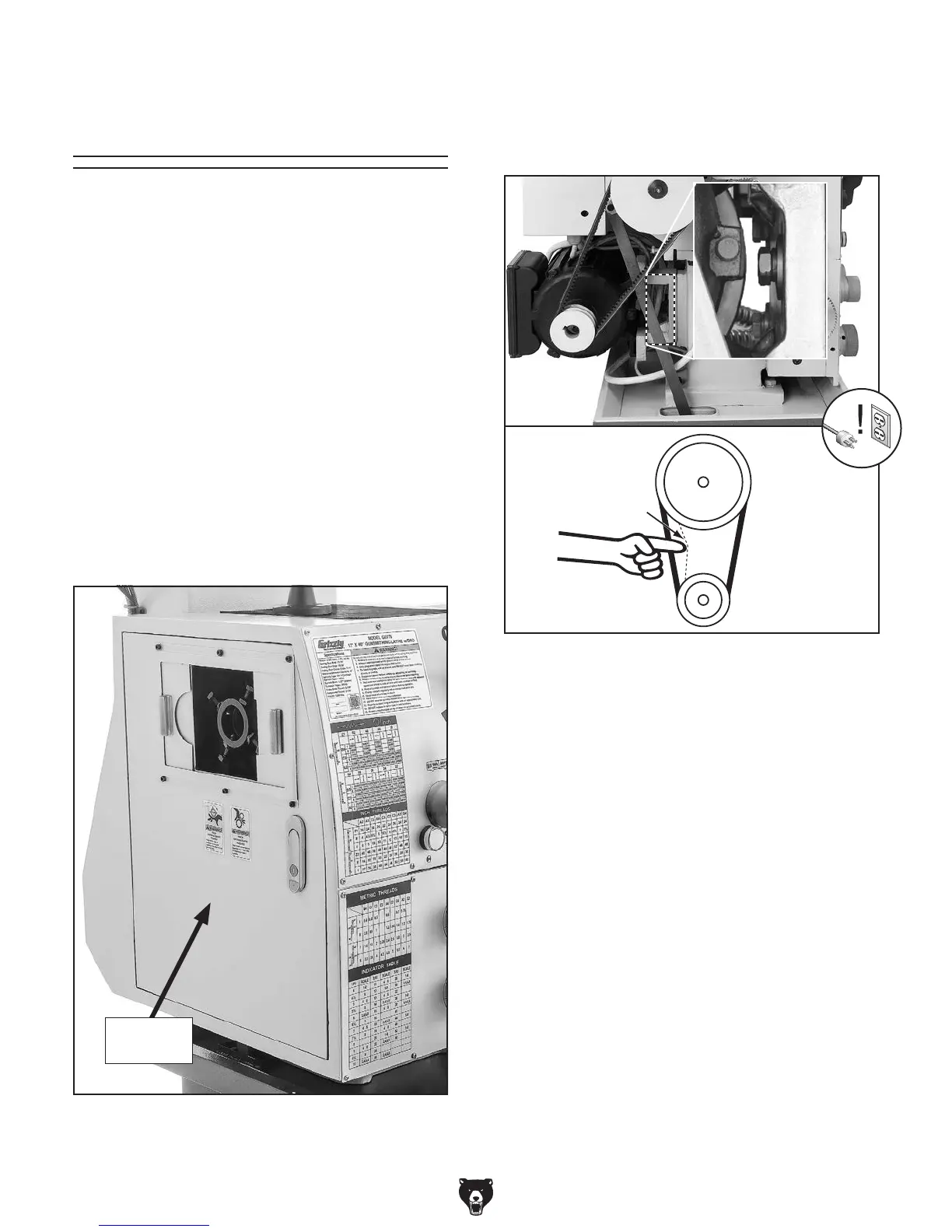

3. Adjust hex nuts on motor mount bolts (see

Figure 141) until there is approximately

3

⁄4"

deflection in each V-belt when it is pushed

with moderate pressure.

Motor

Mount

Bolts

Pulley

Deflection

Pulley

3

⁄4"

Figure 141. Location of motor mount bolts.

4. Firmly tighten hex nuts to secure setting, then

re-install motor access panel and close end

gear cover.

Replacing V-Belts

1. DISCONNECT LATHE FROM POWER!

2. Open end gear cover.

3. Loosen motor mount bolts (see Figure 141),

slide motor up, and remove V-belts.

Note: It may be more convenient to access

the motor mount bolts if you first remove the

rear splash guard.

4. Install new V-belts as a matched set so they

equally share the load.

5. Tension belts.

6. Re-install and secure end gear cover.

Loading...

Loading...