Model G0776 (Mfd. Since 7/14)

-69-

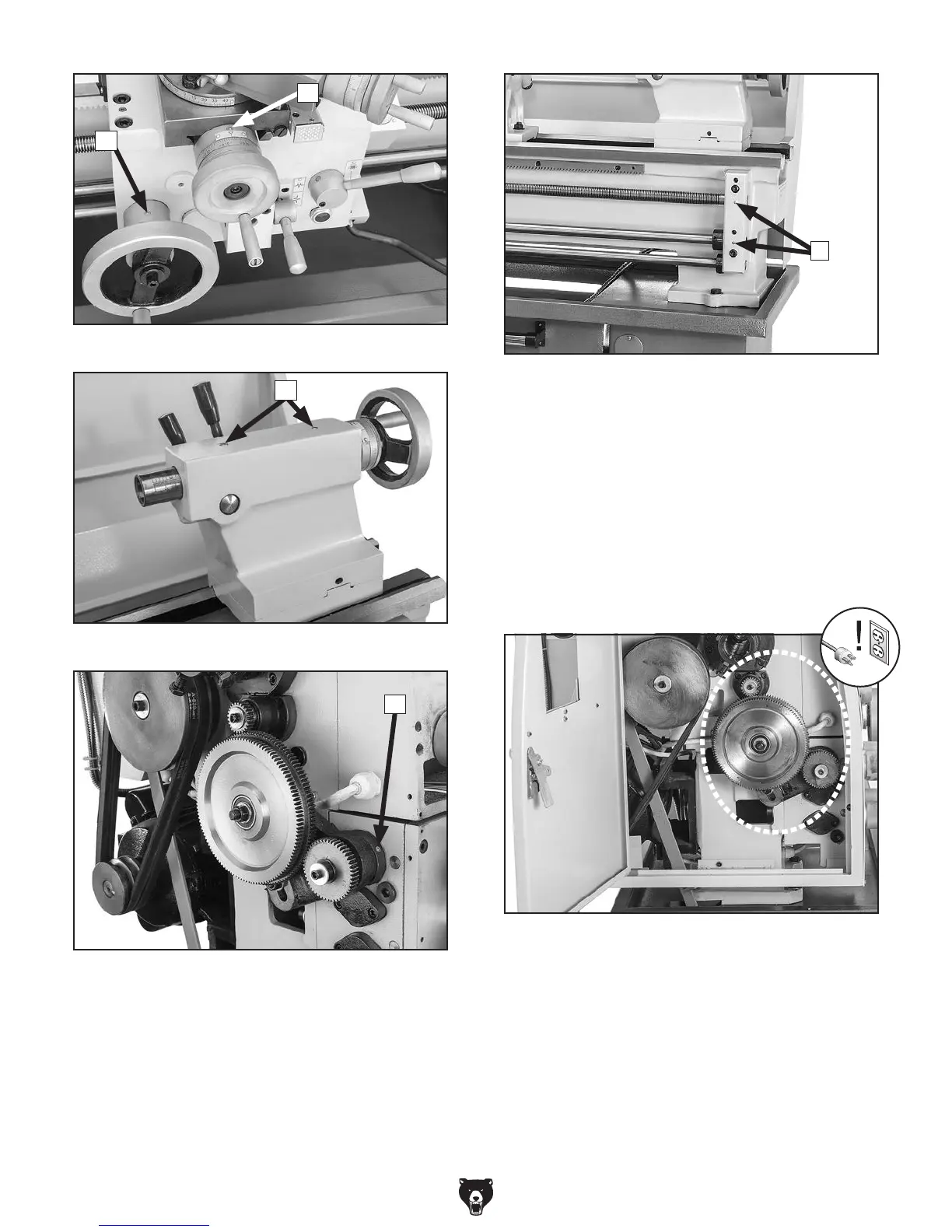

Figure 121. Handwheel ball oilers.

Figure 122. Tailstock ball oilers.

Figure 123. Change gear hub ball oiler.

Figure 124. End cap ball oilers.

End Gears

Grease Type ........ T23964 or NLGI#2 Equivalent

Lubrication ................. Every 50 Operating Hours

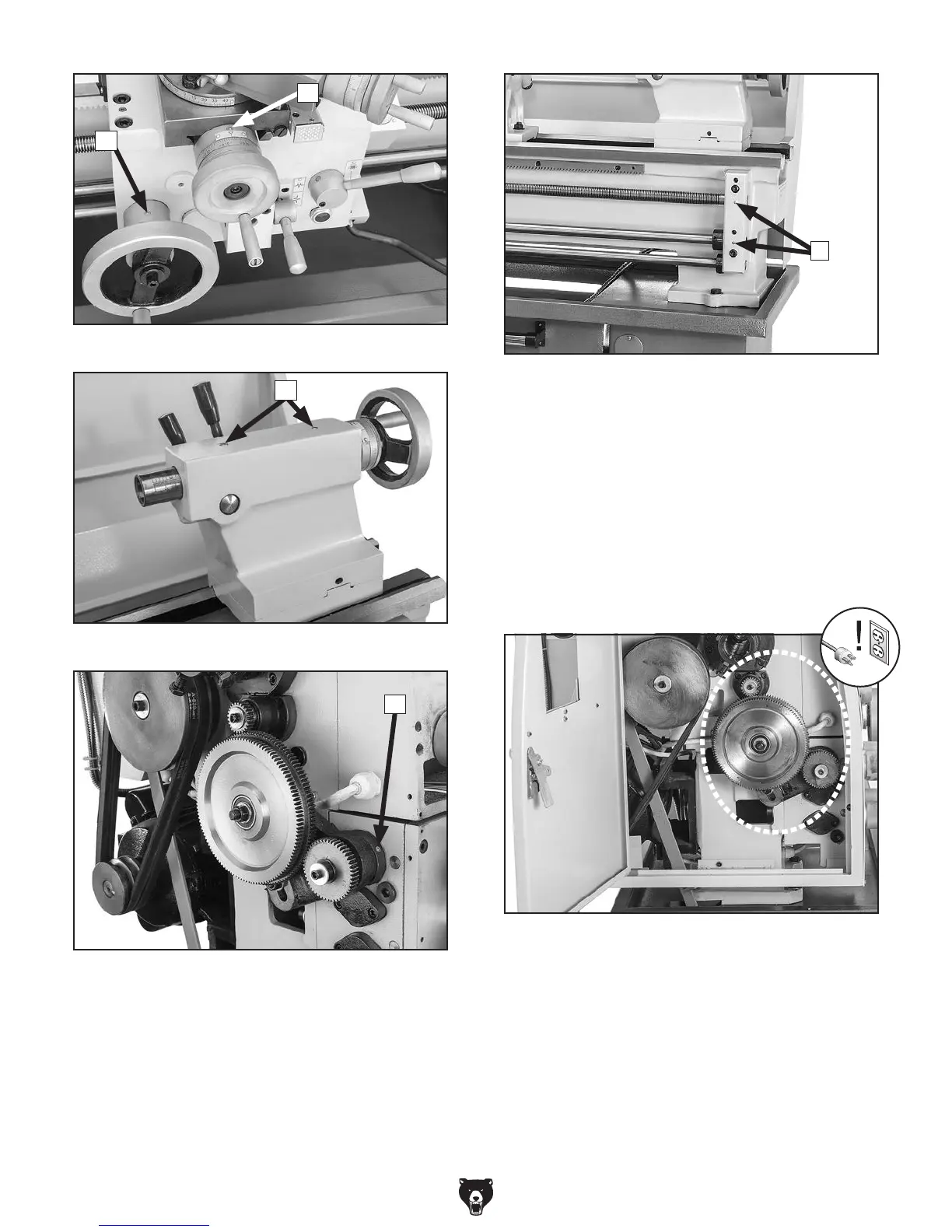

The end gears, shown in Figure 125, should

always have a thin coat of heavy grease to

minimize corrosion, noise, and wear. Wipe away

excess grease that could be thrown onto the

V-belts and reduce optimal power transmission

from the motor.

Figure 125. End gears.

Handling & Care

Make sure to clean and lubricate any gears you

install or change. Be very careful during handling

and storage—the grease coating on the gears will

easily pickup dirt or debris, which can then spread

to the other gears and increase the rate of wear.

Make sure the end gear cover remains closed

whenever possible to keep the gears free of dust

or debris from the outside environment.

D

E

F

G

H

Loading...

Loading...